Preparation method of anti-corrosion and anti-friction synergistic coating on the surface of light alloy and composite material

A composite material and light alloy technology, applied in the field of material engineering, can solve problems such as few reports, and achieve the effects of good corrosion resistance, process stability and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: A method for preparing a corrosion-resistant and wear-reducing Concord coating on the surface of a magnesium alloy, comprising the following steps:

[0036] Pretreatment: The magnesium alloy sample was first polished with sandpaper, then cleaned with acetone, and finally rinsed with deionized water for later use. Then complete the preparation in the following steps:

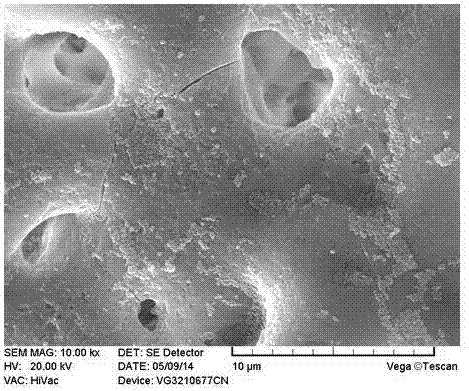

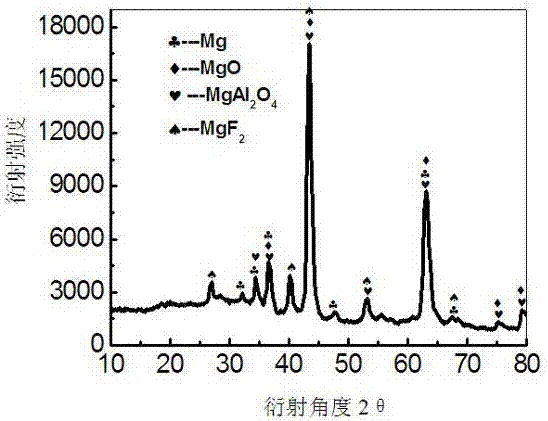

[0037] The first step: prepare a porous base layer on the surface of the magnesium alloy sample by plasma electrolytic oxidation:

[0038]First prepare the electrolyte according to sodium silicate 5g / L, sodium hydroxide 1g / L, potassium fluoride 5 g / L, and hydrogen peroxide 3ml / L, and the solvent is deionized water; then import the above electrolyte into the stainless steel tank as the cathode , the magnesium alloy sample was used as the anode, and the porous base layer was prepared by plasma electrolytic oxidation treatment on the magnesium alloy sample by means of DC pulse power output. Th...

Embodiment 2

[0044] Embodiment 2: A method for preparing a corrosion-resistant and wear-reducing Concord coating on the surface of an aluminum alloy, comprising the following steps:

[0045] Pretreatment: The aluminum alloy sample was first polished with sandpaper, then cleaned with acetone, and finally rinsed with deionized water for later use.

[0046] The first step: prepare a porous base layer on the surface of the aluminum alloy sample by plasma electrolytic oxidation:

[0047] First prepare the electrolyte according to potassium silicate 15g / L, potassium hydroxide 2g / L, potassium fluoride 10 g / L, and hydrogen peroxide 5ml / L, and the solvent is deionized water; then import the above electrolyte into the stainless steel tank as the cathode , the aluminum alloy sample was used as an anode, and the porous base layer was prepared by plasma electrolytic oxidation treatment on the aluminum alloy sample by means of DC pulse power output. The conditions for plasma electrolytic oxidation trea...

Embodiment 3

[0052] Embodiment 3: A method for preparing a corrosion-resistant and wear-reducing Concord coating on the surface of a magnesium-based alloy, comprising the following steps:

[0053] Pretreatment: The magnesium-based composite material sample was first polished with sandpaper, then cleaned with acetone, and finally rinsed with deionized water for later use.

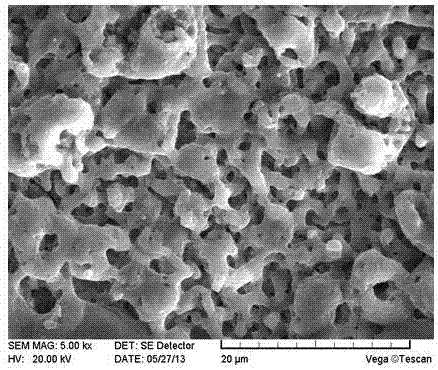

[0054] The first step: prepare a porous base layer on the surface of the magnesium-based composite material sample by plasma electrolytic oxidation:

[0055] First prepare the electrolyte according to sodium silicate 20g / L, sodium hydroxide 3g / L, potassium fluoride 15 g / L, hydrogen peroxide 10ml / L, and the solvent is deionized water; then import the above electrolyte into the stainless steel tank as the cathode , the magnesium-based composite material sample was used as an anode, and the porous base layer was prepared by plasma electrolytic oxidation treatment on the magnesium-based composite material sample by means of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com