Non-self-balancing steel truss long-span arch bridge swivel and its construction method

A long-span arch bridge and non-self-balancing technology, which is applied in the direction of erecting/assembling bridges, bridges, suspension bridges, etc., can solve the problems of high cost, inability to guarantee the vehicles and ships below, and inconvenient traffic, etc., and achieve high safety and smooth construction of bridge body rotation , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

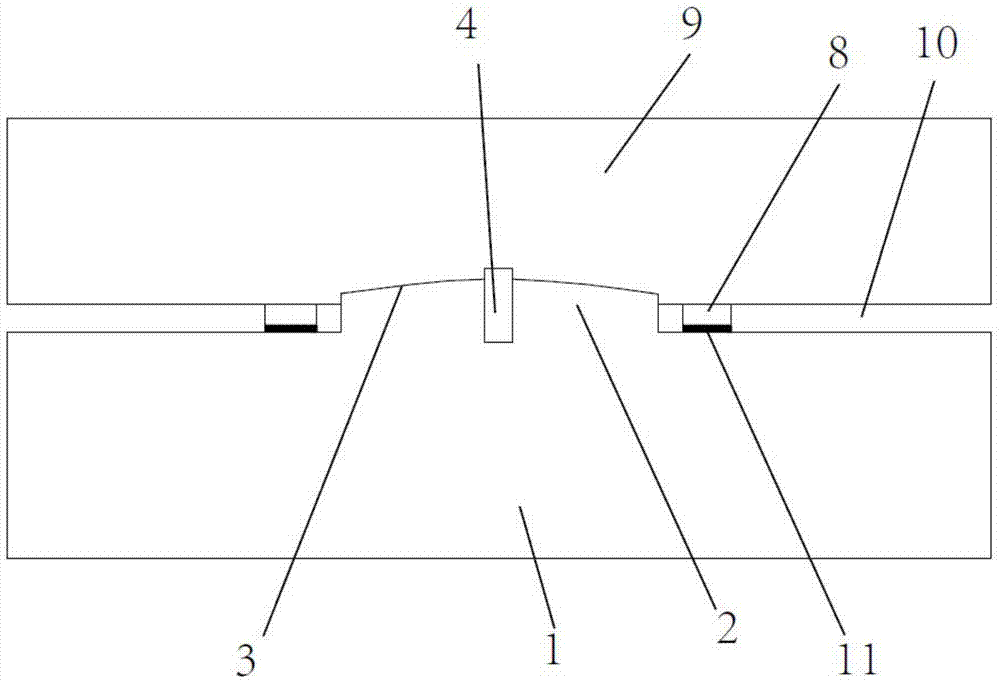

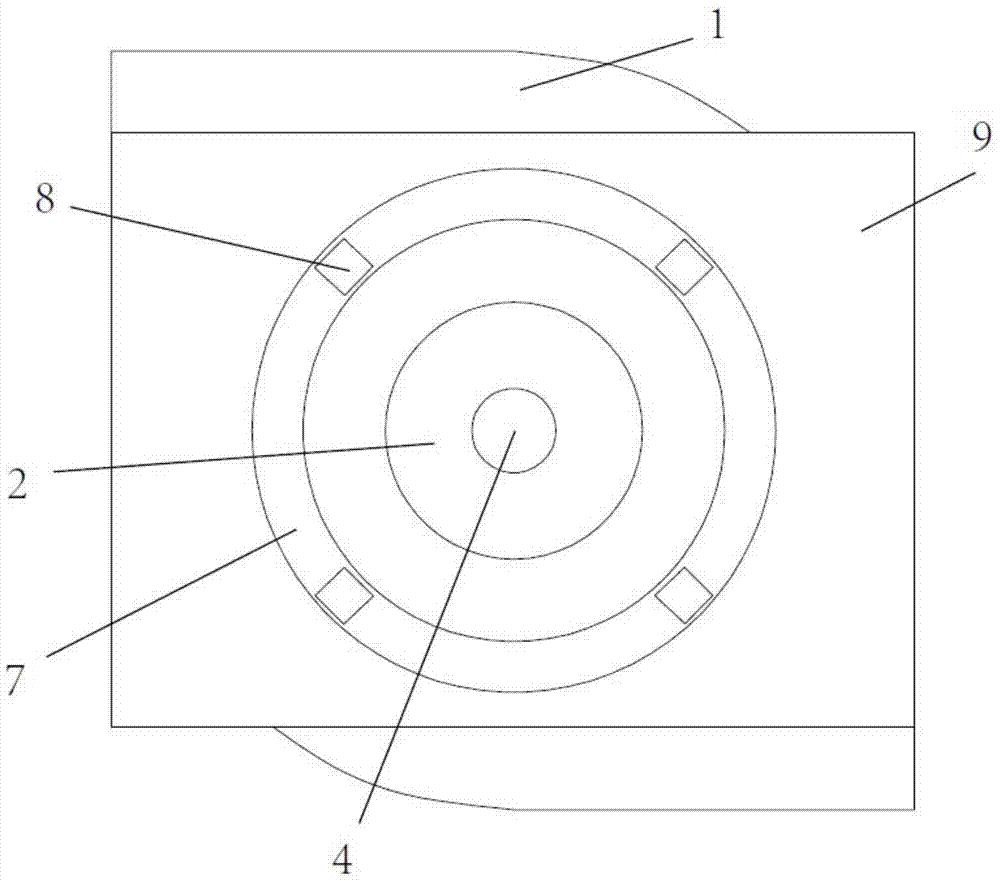

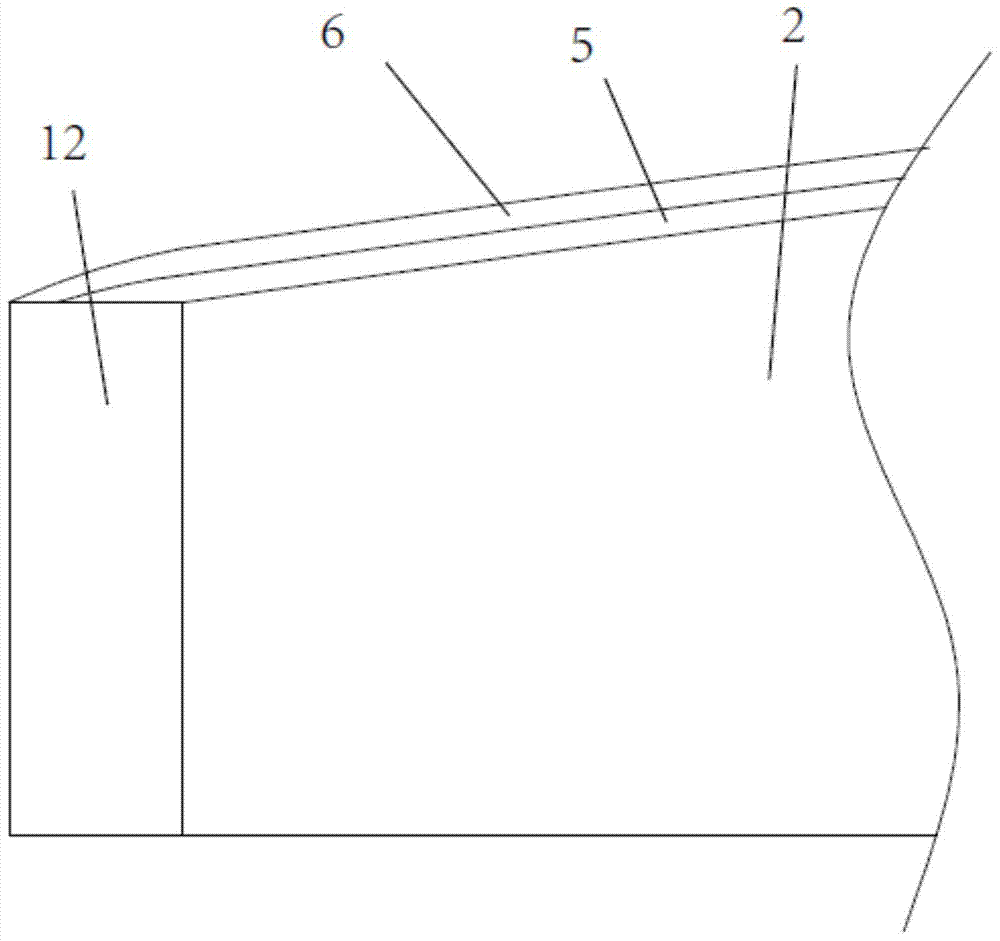

[0032] refer to Figure 1 to Figure 3 As shown, the non-self-balancing steel truss long-span arch bridge swivel includes a base platform 1, the surface of the base platform is provided with a lower millstone 2, the surface of the lower millstone is set as a conical surface 3, and the middle part is provided with a central pillar 4, the conical surface The surface is coated with an isolation layer 5 and a lubricating layer 6 in turn. A circle of slides 7 is also arranged on the base platform around the lower grinding disc. Several buttresses 8 are arranged on the sliding track. An upper turntable 9 is also arranged on the lower grinding disc. The bottom of the upper turntable corresponding to the millstone is provided with a groove of the same shape as the lower millstone and the central pillar, the bottom of the upper turntable is also connected to the top of the pier, and an overhead space 10 is provided between the bottom of the upper turntable and the base platform.

[0033...

Embodiment 2

[0049] The difference between Embodiment 2 and Embodiment 1 is that the thickness of the isolation layer is 2 mm, the thickness of the lubricating layer is 1 mm, and the thickness of the out-of-circle isolation ring is 1.5 cm. The fit is good and the shaking caused by the gap is reduced.

Embodiment 3

[0051] The difference between Embodiment 3 and Embodiment 1 is that the thickness of the isolation layer is 5mm, the thickness of the lubricating layer is 4mm, and the thickness of the out-of-round isolation ring is 5cm, which reduces the construction difficulty.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com