Overweight combined highway and railway bridge rigid suspending cable stiffened continuous steel trussed beam pushing device with stiffening string

A technology of road-rail dual-purpose bridge and jacking device, which is applied in the field of bridge steel structure, can solve problems such as inability to meet the jacking requirements, and achieve the effect of ensuring stability and safety and ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

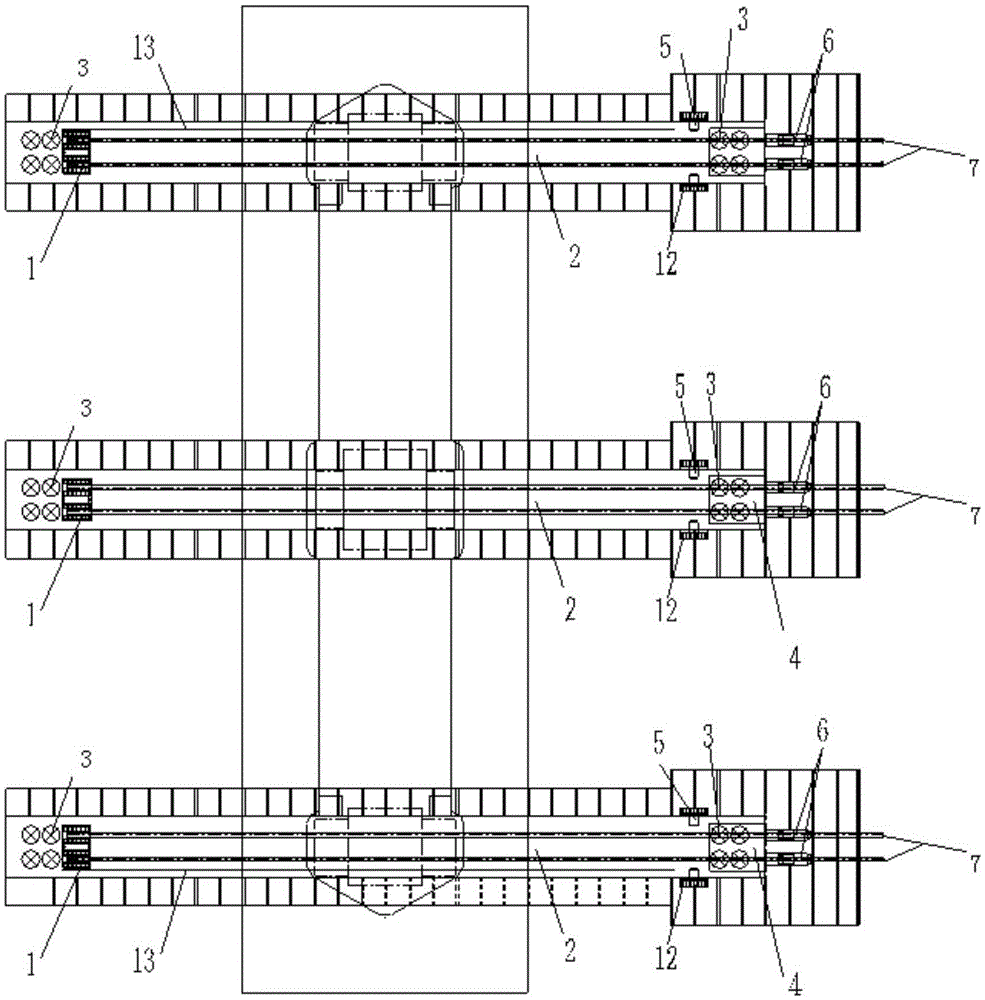

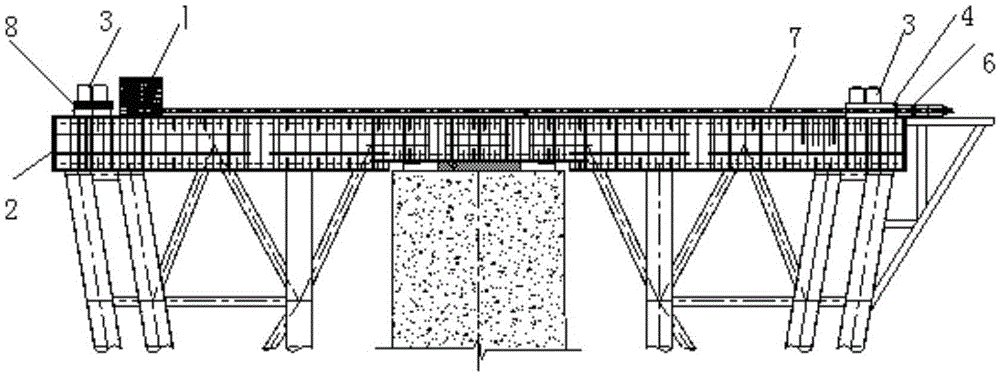

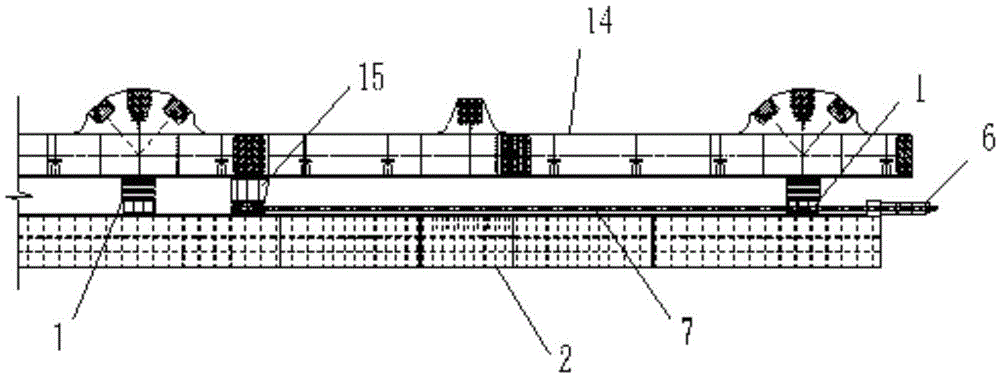

[0019] Referring to the accompanying drawings, a rigid suspension cable-stiffened continuous steel truss beam with stiffened chord thrusting device for a super-heavy road-rail dual-purpose bridge includes a sliding device, a vertical jacking device, a horizontal jacking system device, and a lateral deviation correction device. In that: the sliding device includes left, middle and right three-truss sliders 1 and a slideway beam 2, the left, middle and right three-truss sliders 1 are respectively located above the slideway beam 2, and the left, middle and right three The bottom of the truss slider 1 is respectively equipped with an MGE material slide plate 10 for oil passage, and the top of the slideway beam 2 is laid with a full-length MGE material stainless steel plate 12; Jacking jack 3, horizontal reaction force seat 4, distribution beam 8, said horizontal reaction force seat 4 is fixed on the front end of slideway beam 2, said distribution beam 8 is respectively placed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com