Concrete precast beam and girder connecting structure

A technology for connecting structures and concrete, applied in building structures, buildings, etc., can solve the problems of beams that do not fully play the role of full cross-section, hinder the construction of a low-carbon, harmonious society, and inflexible separation and equipment layout. Uniform and reasonable stress distribution, improved engineering quality, and improved rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creation features, achievement goals and effects of the present utility easy to understand, the present utility will be further described below in conjunction with the specific illustrations.

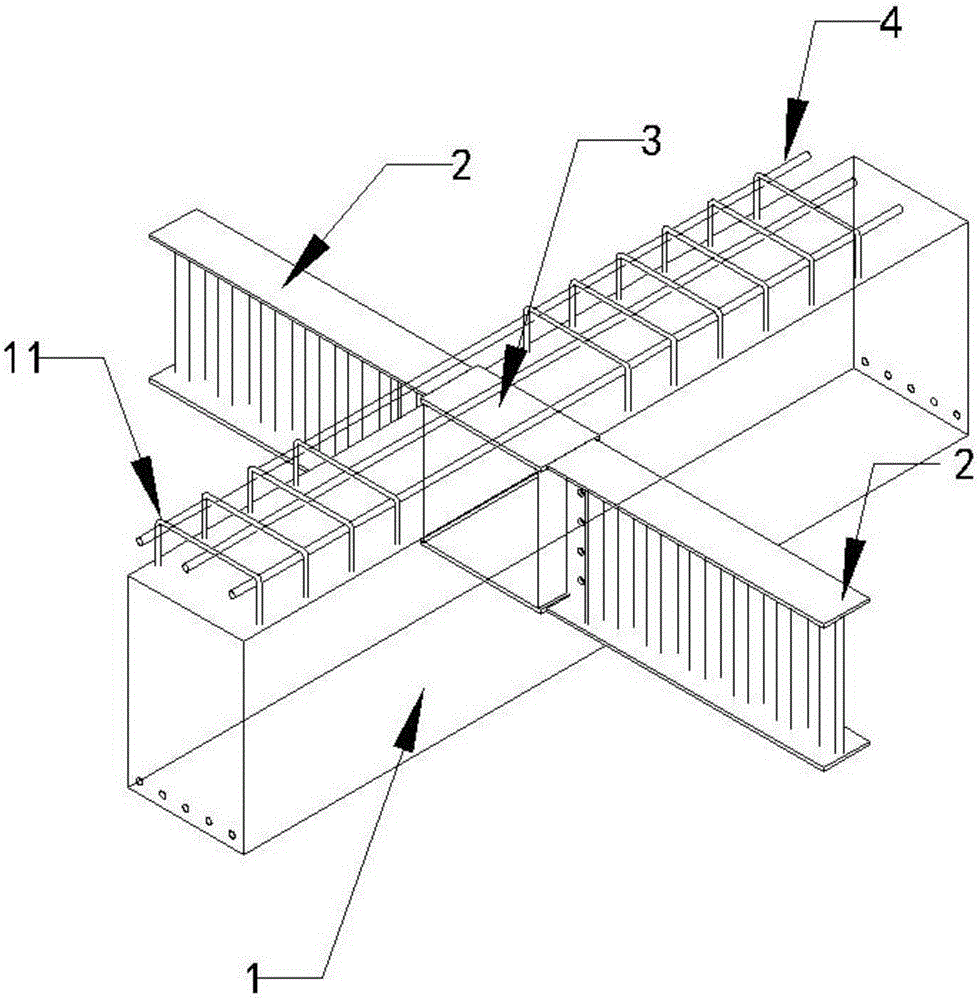

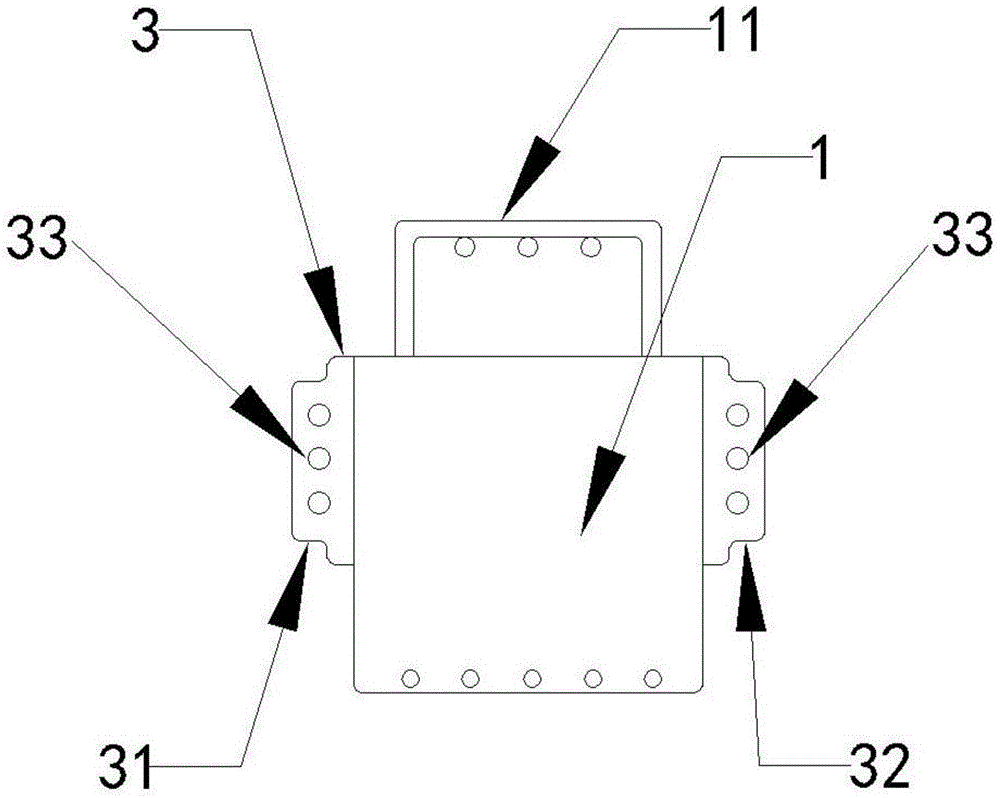

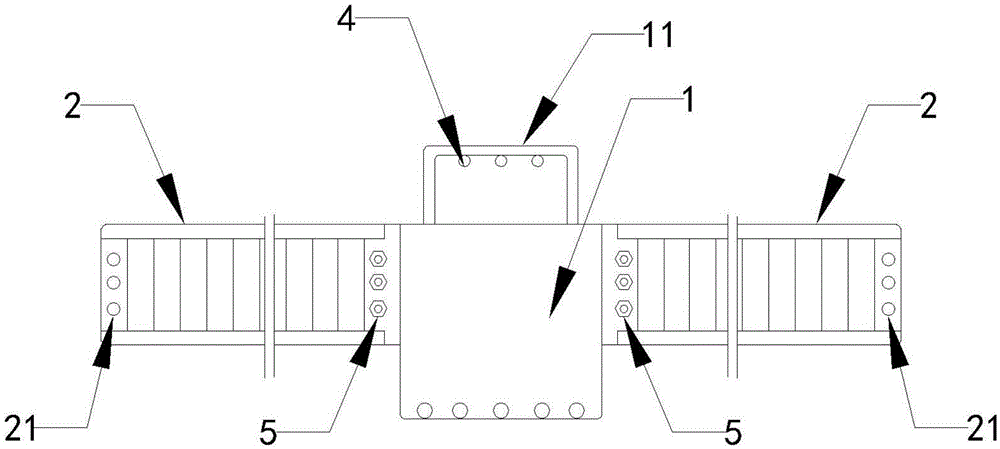

[0017] see Figure 1-3 , a connection structure of a concrete prefabricated beam and a steel beam, which comprises a precast concrete composite beam 1 and a factory prefabricated steel structure beam 2, and the concrete composite beam 1 is installed between adjacent main beams and ends Fixed with the main beam by the node connector, the embedded part 3 is provided on the main body of the concrete composite beam 1 in the extending direction. The connecting plate I31 and connecting plate II32 are symmetrically arranged on both sides of the extension direction of the concrete composite beam 1, and bolt holes I33 are formed on the connecting plate I31 and connecting plate II31 respectively. 2. The two ends of the extension direction are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com