Greenhouse wall and installation method

A wall and cement board technology, applied in the field of greenhouses, can solve the problems of easy crack deformation, poor thermal insulation effect, and high wall construction cost, and achieve the effects of low overall construction cost, good thermal insulation effect and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

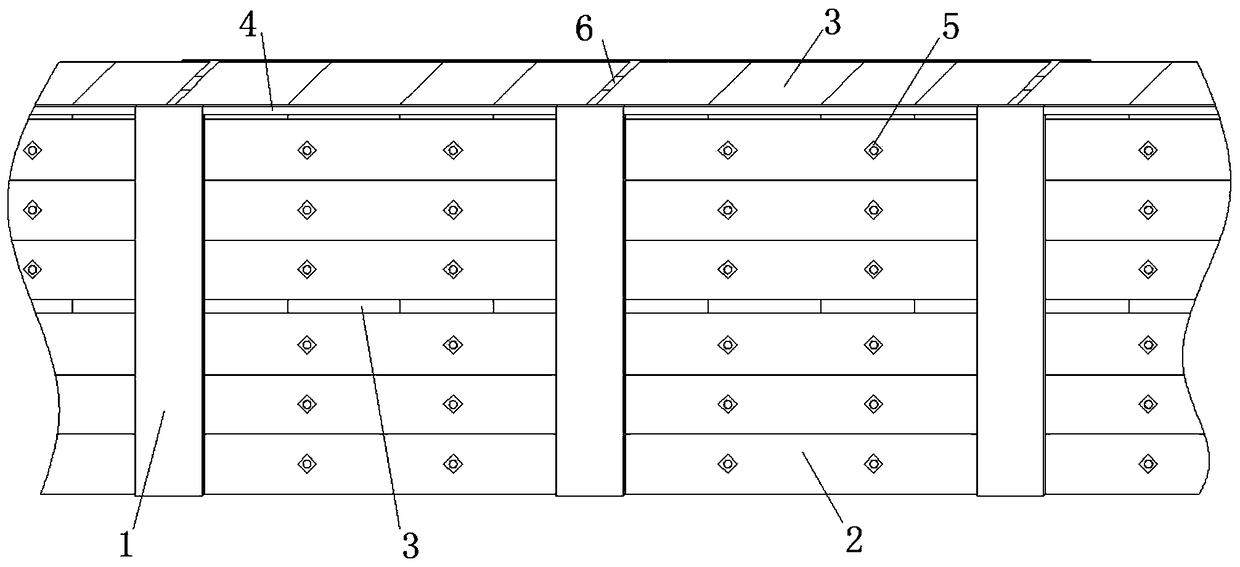

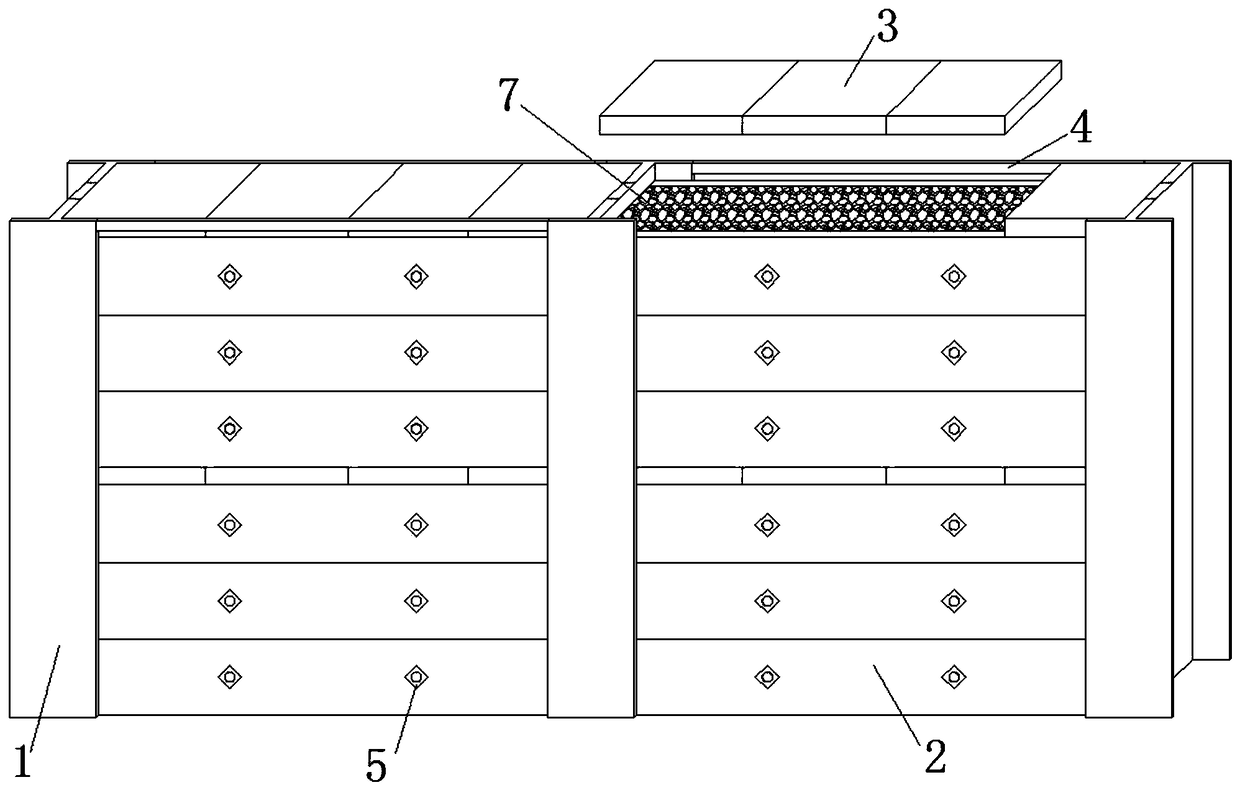

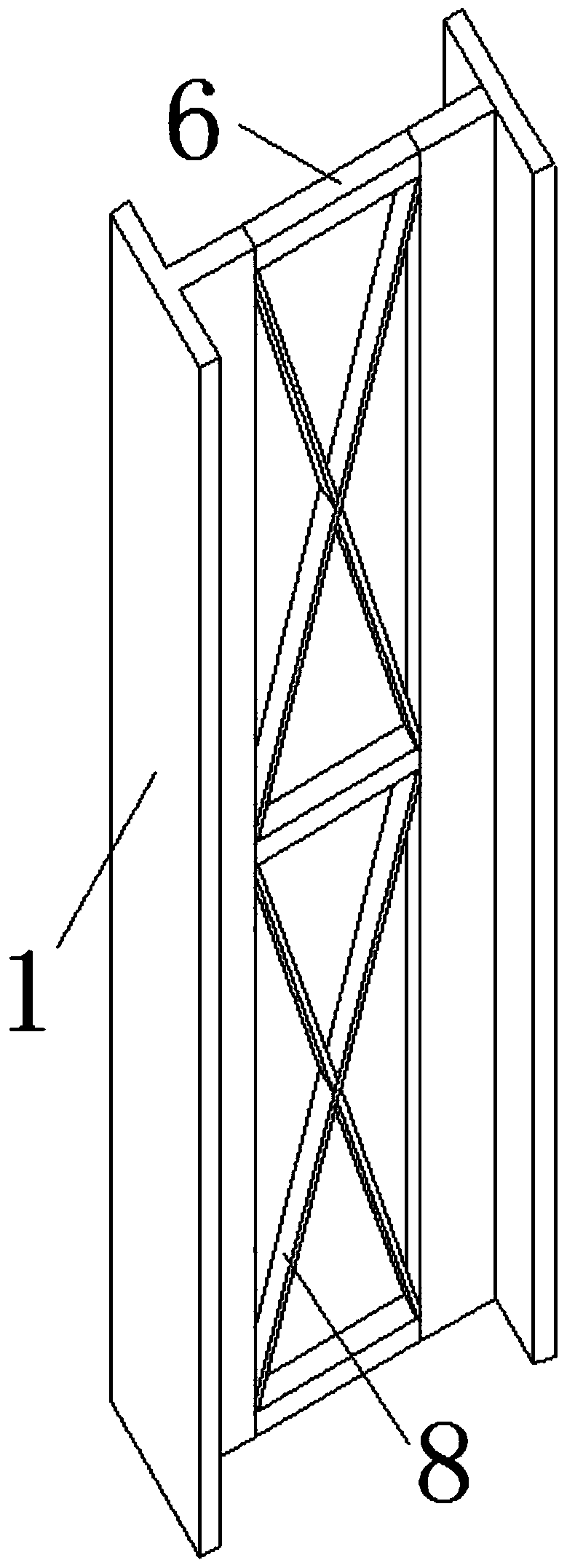

[0032] Such as figure 1 with figure 2 Shown, described greenhouse wall body comprises column, long cement board 2 and soil layer 7, and long cement board 2 and short cement board 3 below are the finished products that are produced by specialized manufacturers. The uprights are evenly spaced on the same straight line, and each upright includes two T-shaped irons 1. The middle plates of the two T-shaped irons 1 are arranged opposite to each other and connected together. The specific connection method is as follows: image 3 As shown, the two intermediate plates are connected together through the connecting plate II6, which can be a triangle iron, and connecting ribs 8 are provided between the connecting plates II6, as shown in image 3 As shown, the cross setting pulls two T-shaped irons 1 to increase the strength of the structure. The bottom plates of the two T-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com