Implementing method for reinforcing concrete transformation frame by winding fiber bundle yarns

A technology of substation structure and implementation method, which is applied in the directions of building maintenance, building structure, building type, etc., can solve the problems of long reinforcement construction period, power outage of substation, easy damage and failure, etc., so as to achieve short reinforcement construction period and improve structural durability. Sex, the effect of a wide range of trials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

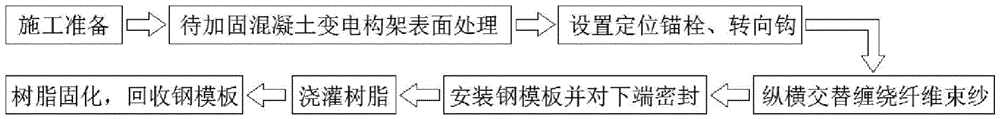

[0043] Such as figure 1 As shown, the method for implementing the winding fiber bundle yarn of the present invention to strengthen the concrete transformer structure comprises the following steps:

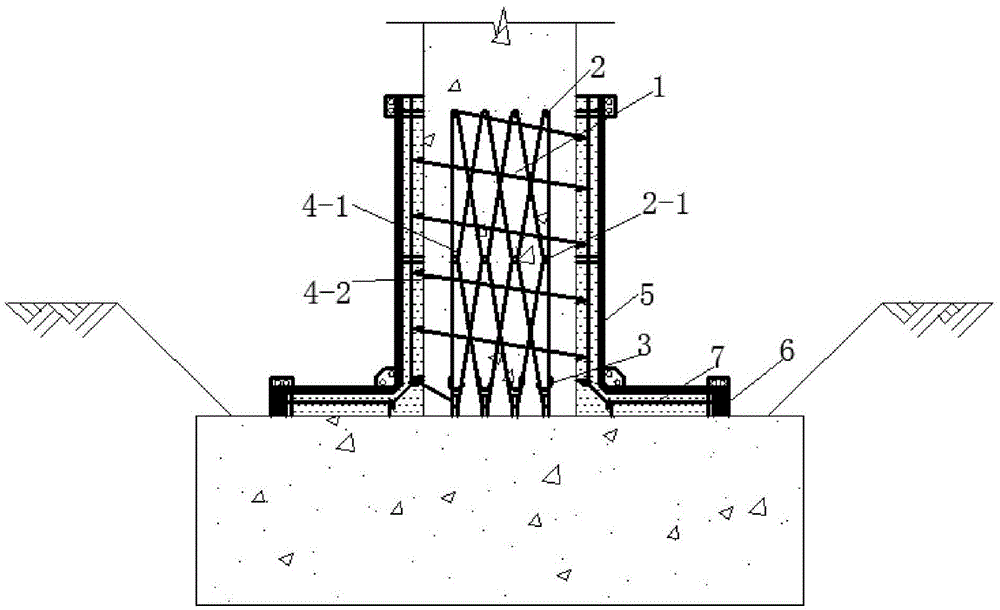

[0044] 1) Surface treatment is carried out on the surface area of the concrete substation frame 1 to be reinforced, and only the new structural surface is exposed. When strengthening the column foot, the covering soil should be excavated first to expose the original basic structure;

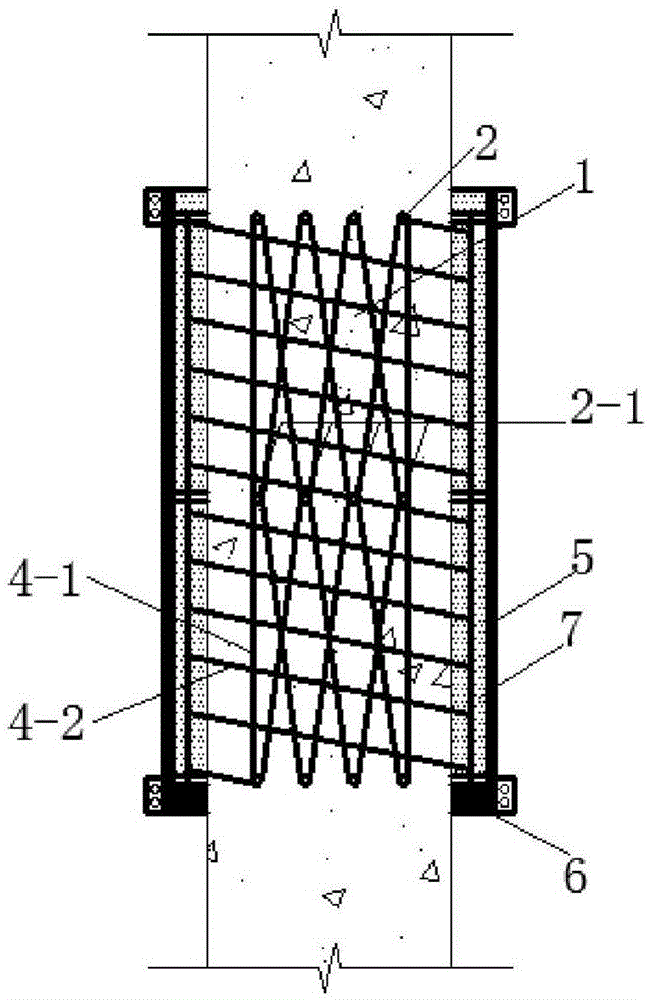

[0045] 2) Positioning anchor bolts 2 and steering hooks 3 are arranged on the upper and lower edges of the area to be reinforced. If the length of the upper and lower edges is greater than 50cm, one or more anchor bolts 2-1 can be added in the middle of the reinforcement area as appropriate;

[0046] 3) Winding the fiber bundle yarns 4-1 and 4-2 onto the positioning pin 2 in an alternate vertical and horizontal manner;

[0047] 4) A steel formwork 5 is set on the periphery of the reinforcement area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com