Plateau honing cross hatch cylinder sleeve used for engine

A platform mesh and cylinder liner technology, applied to engine components, machines/engines, cylinders, etc., can solve problems such as damage to the normal matching of cylinder liners and piston rings, failure of combustion chamber seals, and damage to diesel engine operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

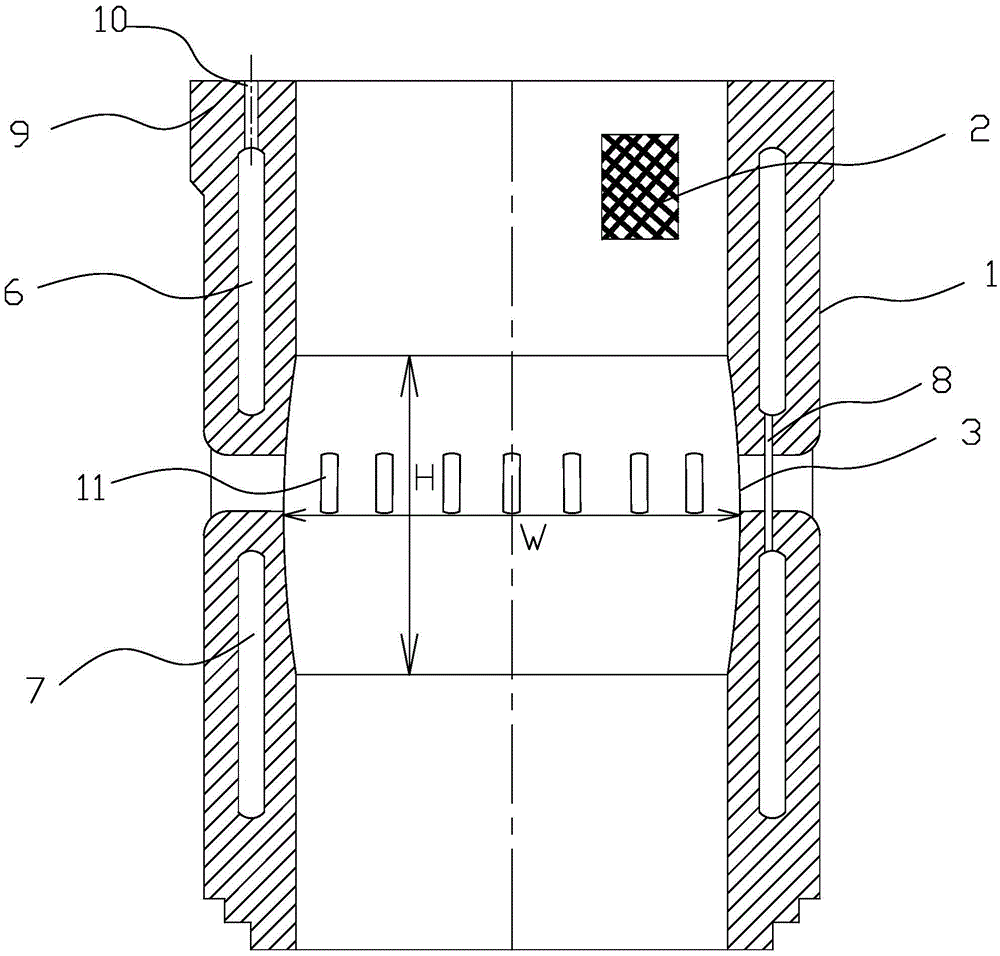

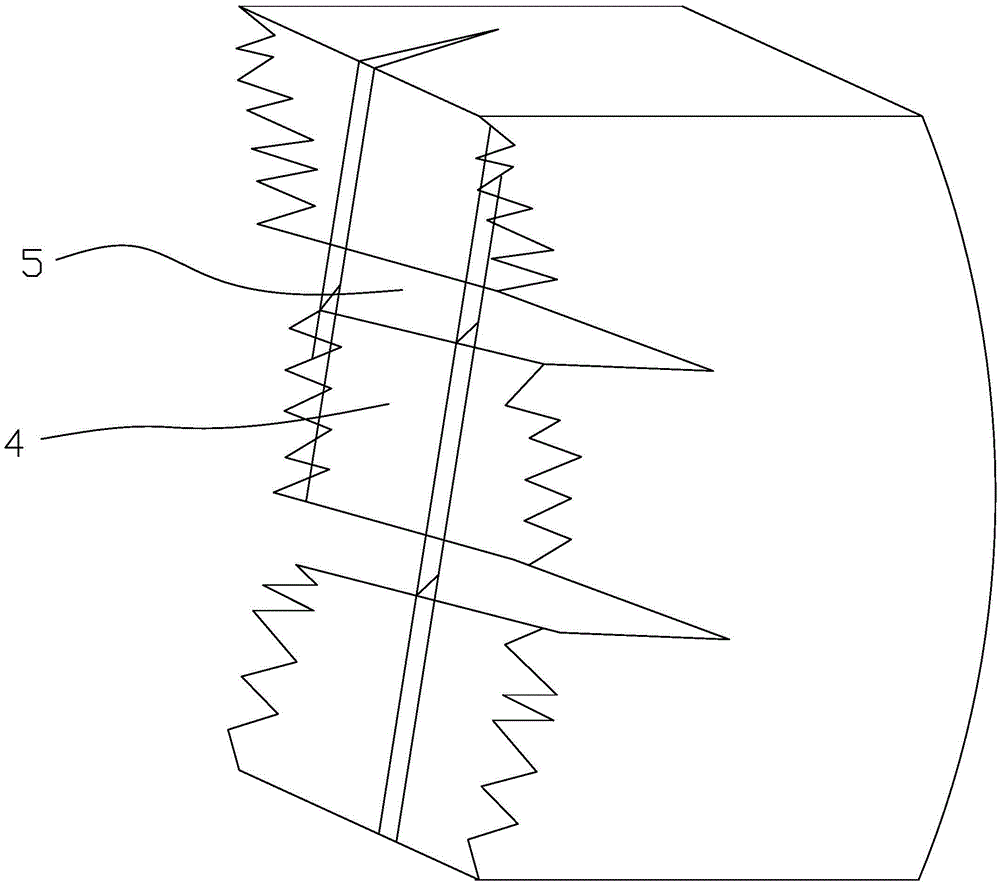

[0019] The present invention as Figure 1-2 As shown, it includes a cylinder liner body 1. The cylinder liner body 1 is integrally cast with Aube ductile iron or chrome-molybdenum copper cast iron. The inner wall of the cylinder liner body is provided with a platform honing texture 2, and the middle part 3 of the inner wall is in the shape of a waist drum. type; the drum-shaped area of the cylinder liner body is provided with a number of intake and exhaust ports 11 .

[0020] The waist-drum width W of the cylinder liner body (i.e. figure 1 The ratio of the distance between the midpoints on both sides of the midplane) to the diameter of the cylinder liner body is 0.535-0.7:1, and the ratio of the height H of the waist drum of the cylinder liner body to the diameter of the cylinder liner body is 0.435-0.6:1. The diameter of the cylinder liner body is related to the width and height of the waist drum, so that the curvature of the waist drum is related to the wall thickness of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap