Thermal load adjusting device suitable for organic heat carrier boiler shaping energy efficiency test

A technology for regulating devices and heat loads, applied in the direction of heat exchangers, indirect heat exchangers, fixed conduit components, etc., can solve problems such as the rise of the outlet temperature of the organic heat carrier, the failure of the test to continue normally, and the inability to release heat. Achieve the effects of simple structure, wide adjustment range, and convenient movement and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings; but the present invention is not limited to the following embodiments.

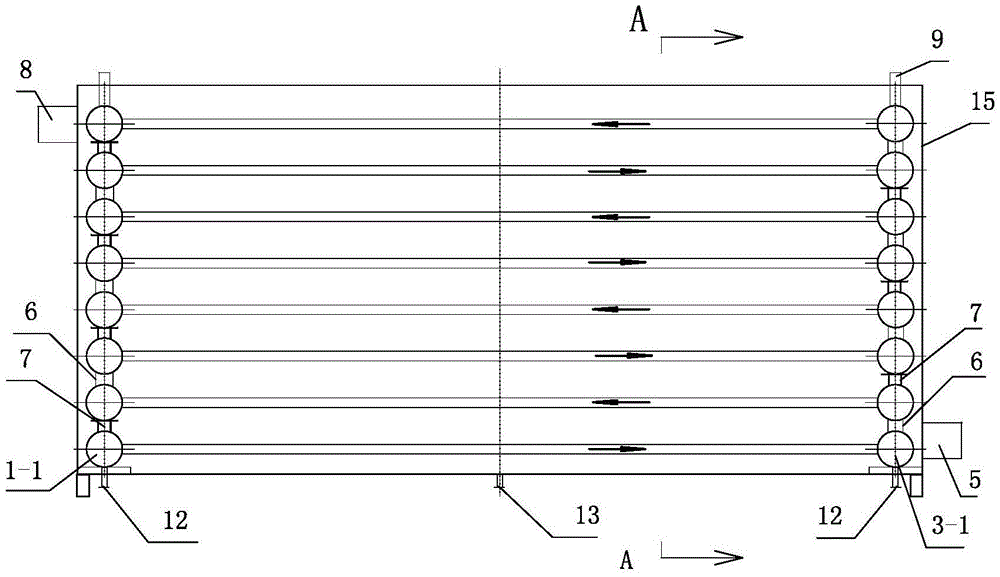

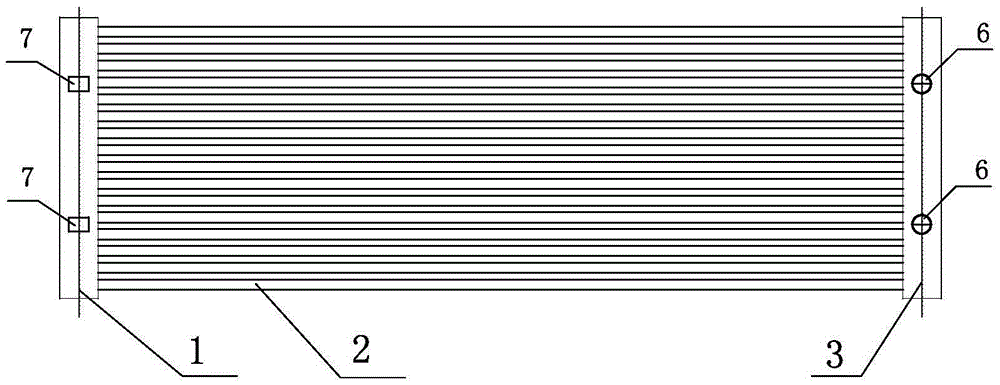

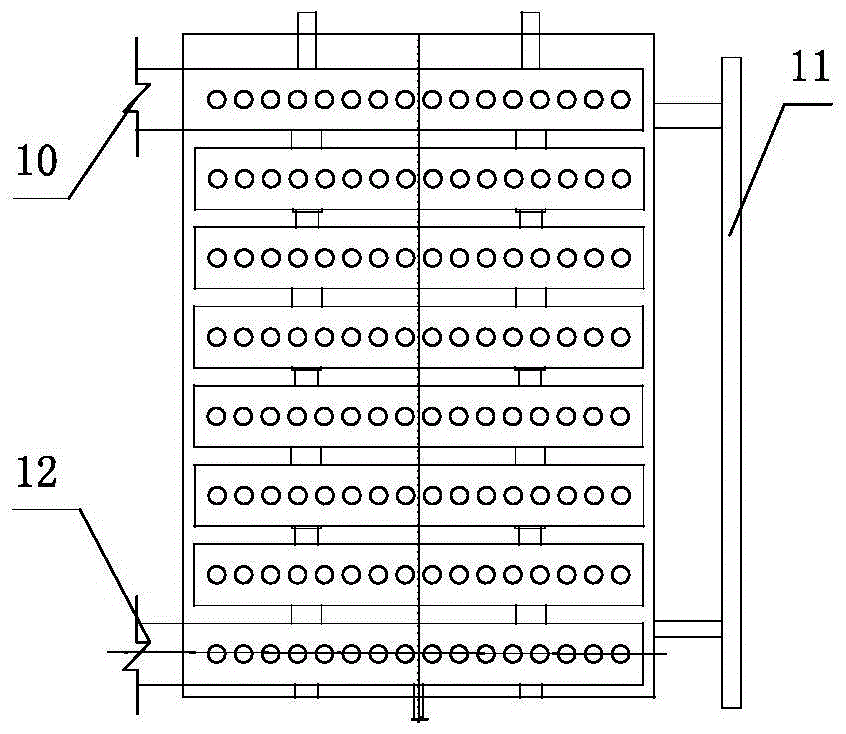

[0022] The thermal load regulating device shown in the attached figure, which is suitable for the energy efficiency test of the organic heat transfer material boiler, is usually installed on the oil return pipeline before the circulation pump of the organic heat transfer material boiler.

[0023] In the regulating device: the casing 15 is a thin-walled container for holding the coolant (usually a metal casing projected as a rectangle on the horizontal plane, preferably made of a steel plate); an organic heat carrier is placed horizontally in the casing Tube panels (hereinafter referred to as heat exchange tube panels), or several interconnected heat exchange tube panels arranged horizontally and neatly stacked up and down, each heat exchange tube panel includes inlet headers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com