Blade foam integrated inspection device

An inspection device, foam technology, applied in the direction of measuring device, adopting mechanical device, mechanical measuring device, etc., to achieve the effect of improving inspection efficiency and ensuring inspection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below.

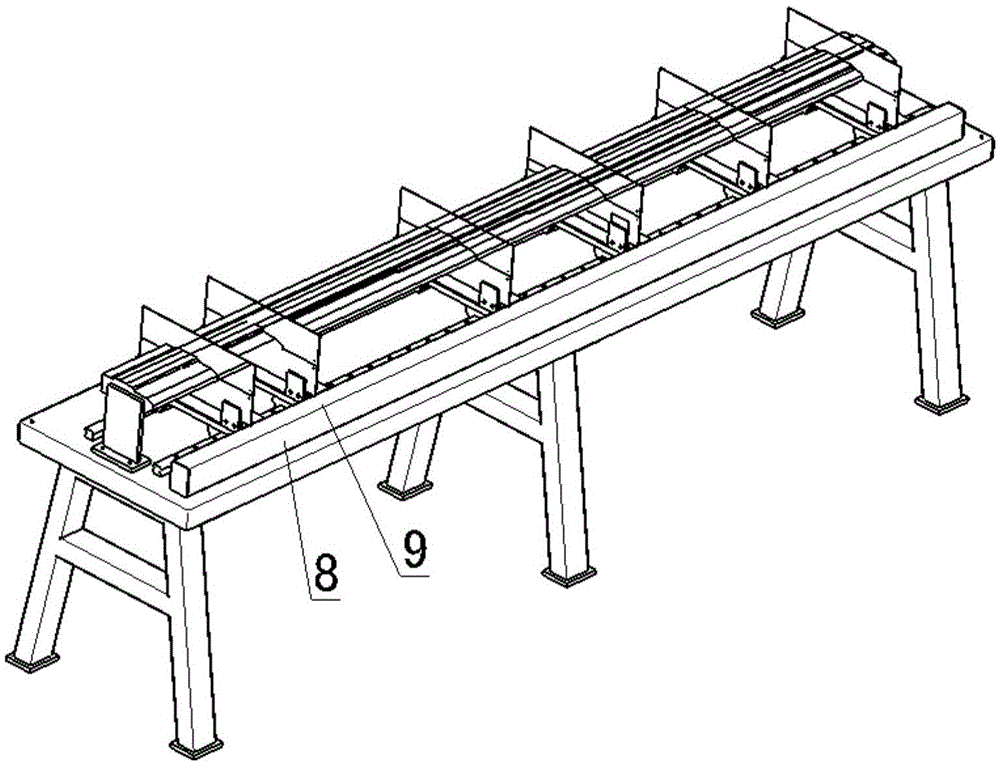

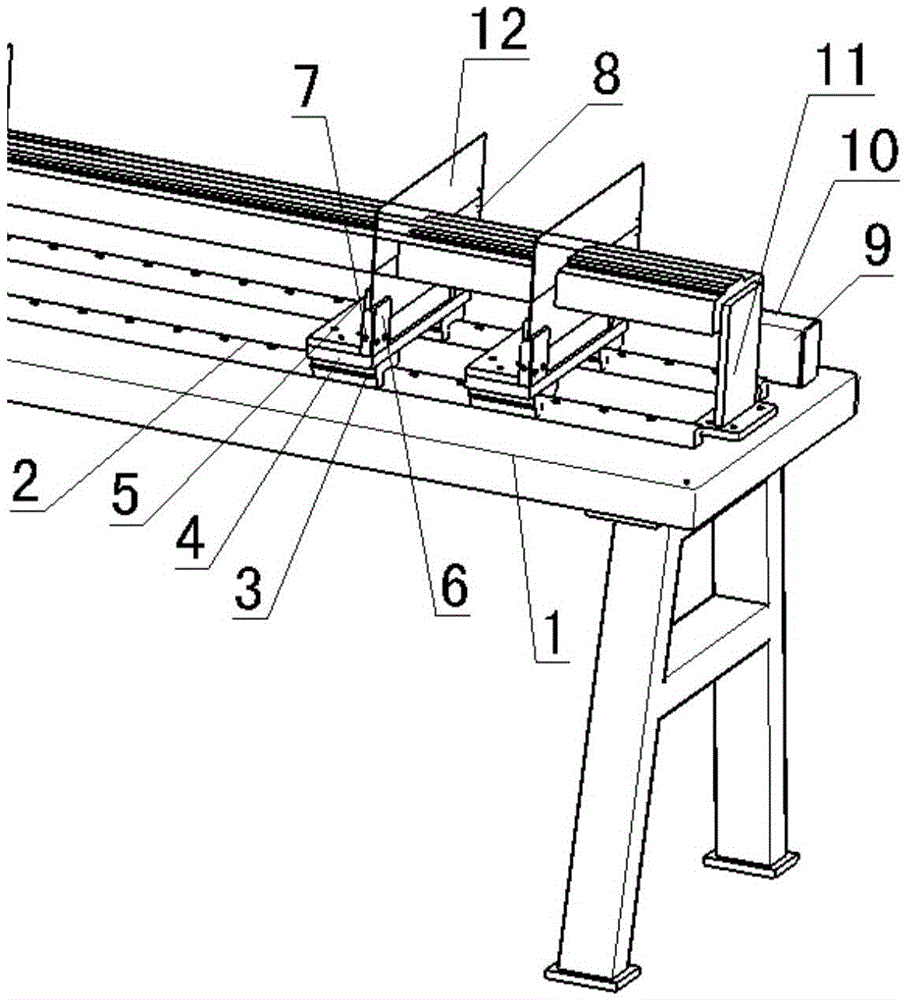

[0013] Two parallel precision guide rails 2 are installed on the platform 1, and a slider 3 is connected to the guide rails. The slider 3 can move smoothly on the guide rails 2. A positioning support 4 is installed on the slider 3. Each end has a U-shaped groove, which can be installed with different lower inspection clamps 8, and a reference block 9 is installed parallel to the guide rail 2, and a scale 10 is installed on the upper surface of the reference block 9. By moving the slider 3 , the protruding part of the inspection card 8 can indicate the corresponding position on the scale 10 , and the position of the inspection card 8 can be quickly determined by this method. The platform 1 is provided with an end face positioning plate 11 for end face positioning of different foams. After the lower inspection pallet 8 is installed in place, the upper inspection pallet 12 is loaded into it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com