Stock bin for sorting particles

A silo and particle technology, which is applied in the field of silo for sorting particles, can solve the problems of large number of particles, laborious inspection, and inability to balance inspection efficiency and inspection accuracy at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

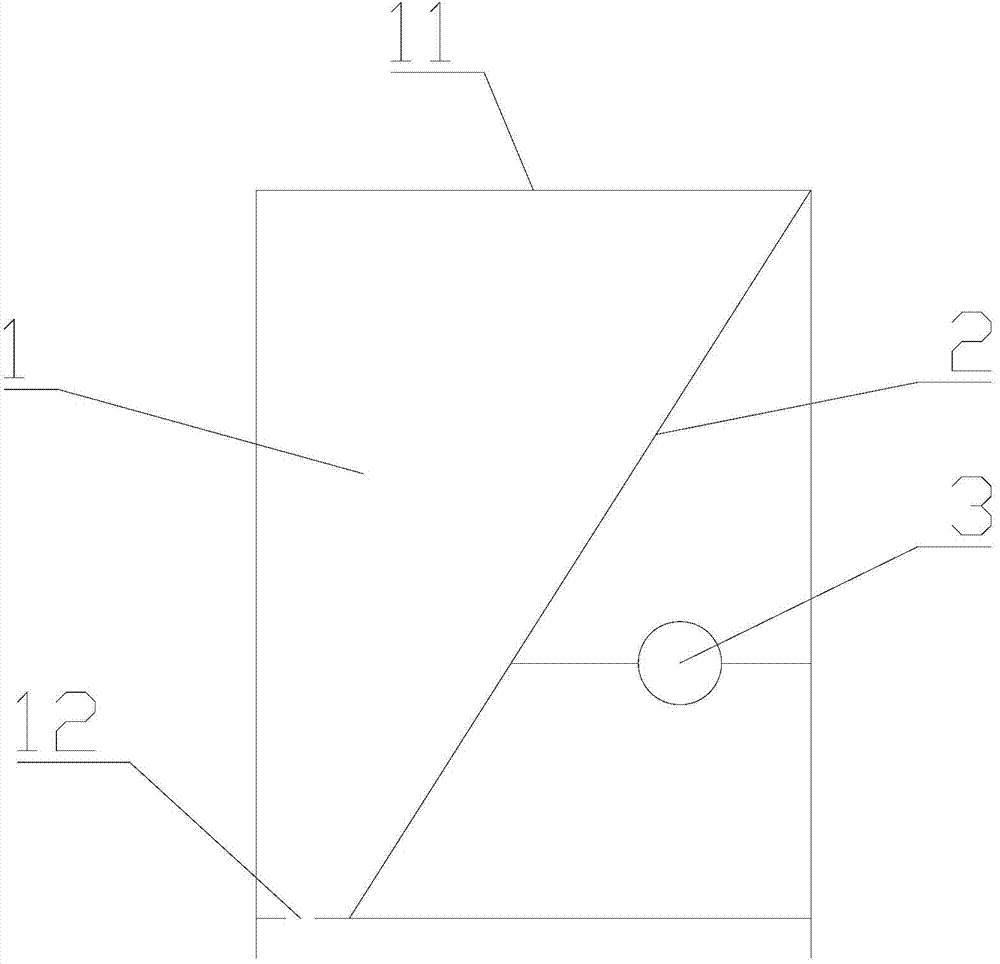

[0011] like figure 1 As shown, a kind of feed bin for sorting particles, the top of the feed bin 1 is opened to form a feed inlet 11, and the bottom of the feed bin is provided with a feed outlet 12. In this embodiment, the feed outlet is a linear strip The silo is equipped with an inclined plate 2, which divides the silo into two inner cavities, one of which is in the shape of an inverted cone and communicates with the discharge port and the feed port, and the other cavity is equipped with a vibrating Mechanism 3 and the vibration mechanism are connected between the inclined plate and the inner wall of the feed bin. Of course, it is also possible to directly set the feed bin as an inverted cone, and the vibrating mechanism is installed on the outer wall of the feed bin.

[0012] Except above-mentioned preferred embodiment, the present invention also has other embodiments, and those skilled in the art can make various changes and deformations according to the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com