Touch substrate, fabrication method for touch substrate, and touch apparatus

A substrate and touch technology, which is applied in the fields of instruments, electrical digital data processing, and data processing input/output processes, etc., can solve problems such as unfavorable touch sensitivity and small capacitive coupling area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

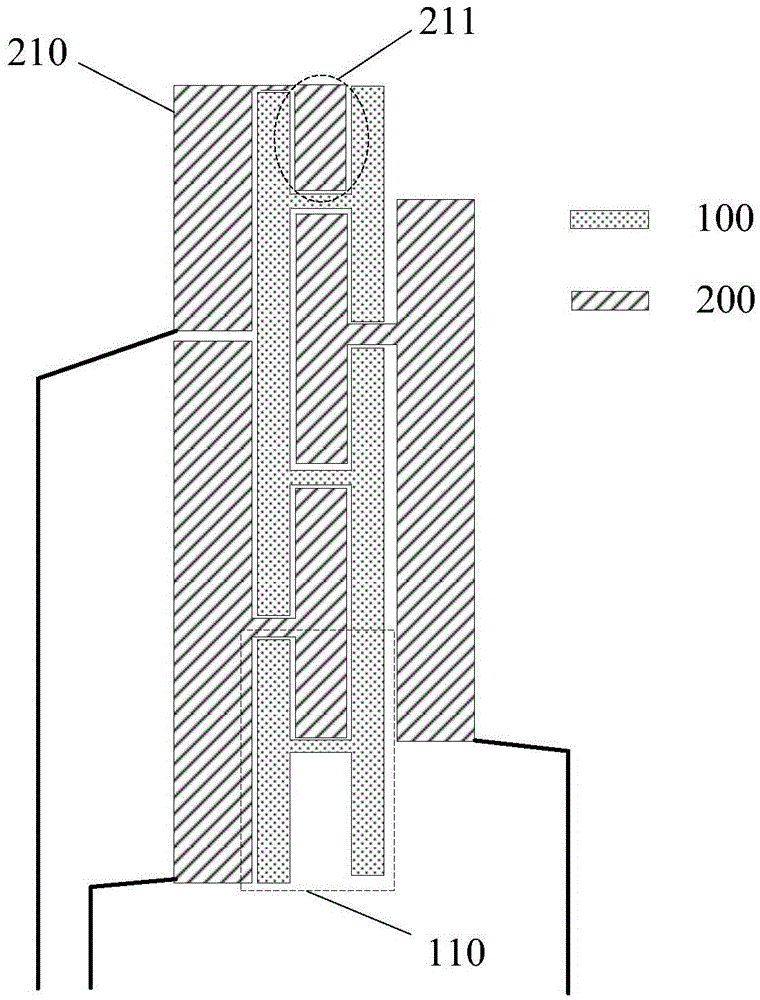

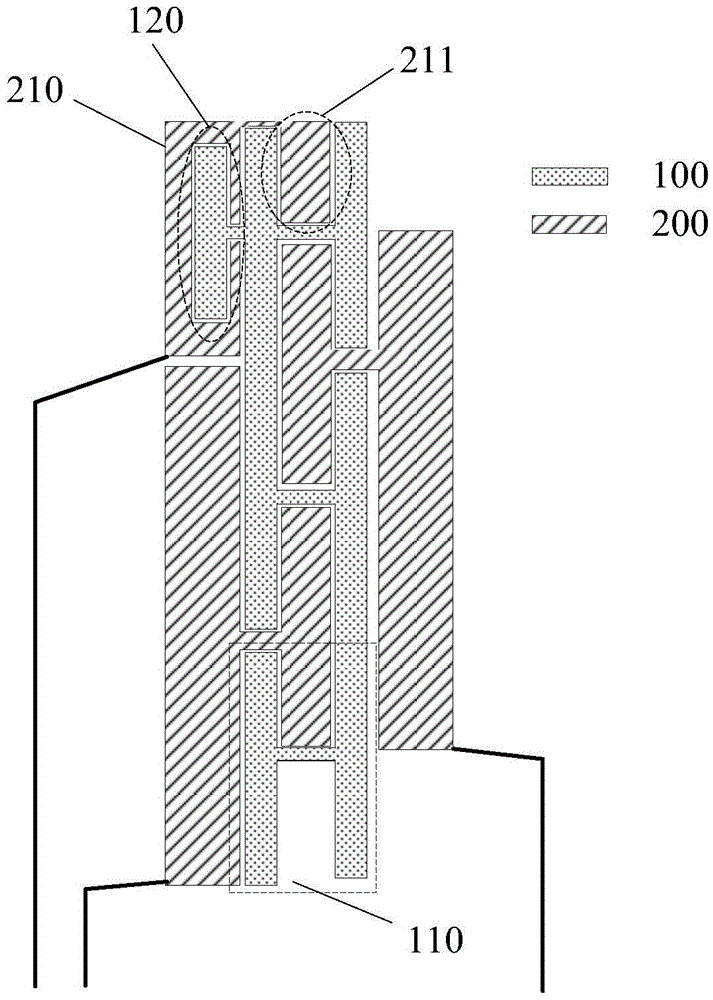

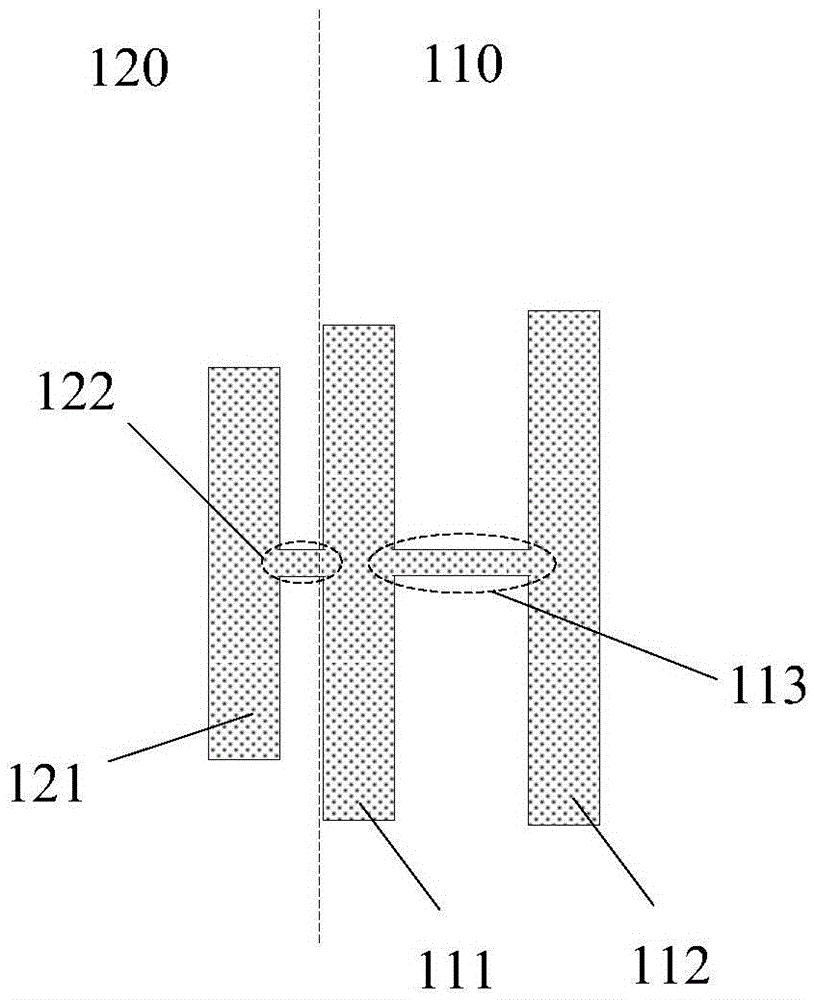

[0027] The structural schematic diagram of the touch substrate provided by an embodiment of the present invention can refer to figure 2 , including a first touch electrode pattern 100 and a second touch electrode pattern 200; wherein the first touch electrode pattern 100 includes a plurality of first touch electrodes 110 and an extended portion 120 at the end; refer to image 3 , is a schematic diagram of the structure of the first touch electrode pattern 100 at the end, including a first touch electrode 110 and a protruding part 120 at this position; wherein, the first touch electrode 110 includes two strip-shaped main parts 111 and 112 and a strip-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com