Full-automatic laminating production line of transformer E-type iron cores

A fully automatic and transformer technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of high work intensity, low production efficiency, and sharp increase in labor costs, and achieve low iron column uniformity and structure Compact, versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

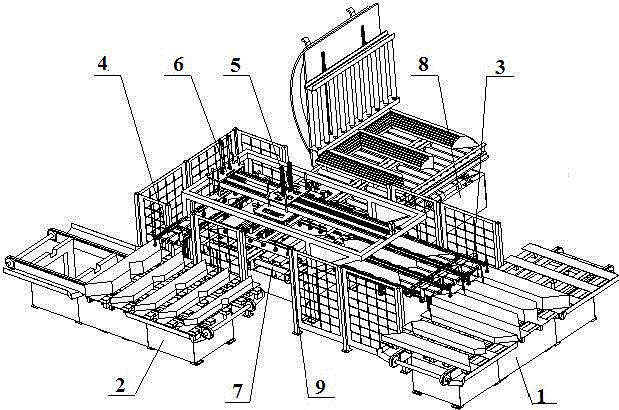

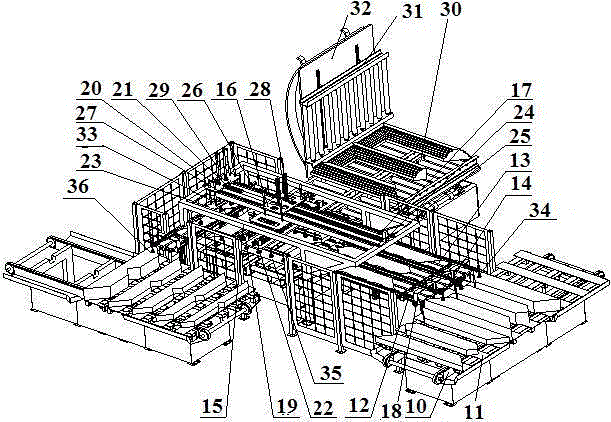

[0028] This embodiment provides a fully automatic stacking production line for transformer E-shaped cores, which includes a three-column feeding device 1 and a three-column transmission and positioning device 3 arranged in a straight line along the feeding direction of the side columns, and a three-column transmission and positioning device 3 sequentially arranged along the feeding direction of the yoke columns. The yoke column feeding device 2 and the yoke column transmission and positioning device 4 arranged in a straight line, the straight line where the three-column transmission and positioning device 3 is located is perpendicular to the straight line where the yoke column transmission and positioning device 4 is located, and the three-column transmission and positioning device 3 and the yoke column A receiving and output device 7 is provided between the transmission and positioning devices 4, and a three-column lamination device 5 and a yoke post lamination device 6 are arr...

Embodiment 2

[0032] On the basis of embodiment 1, this embodiment provides a kind of figure 1 , 2 In the automatic stacking production line for transformer E-type iron cores shown, the three-column feeding device 1 includes a tray base 10 and a feeding tray 11, and a chain mechanism is provided on the tray base 10, and the chain mechanism is for feeding Pallet 11, on the feeding tray 11 there are alternately switched feeding stations and feeding stations, the feeding tray 11 is provided with a magnetic separation device, and the tray chassis 10 is provided with a lifting platform. The yoke column feeding device 2 is the same as the three-column feeding device 1 .

[0033] The three-column transmission positioning device 3 includes three groups of limit guide rails 12 parallel to the feeding direction of the side columns, a fixed-length transmission mechanism 13 arranged on the limit guide rails 12, and a pick-and-place mechanism located at the feed inlet of the fixed-length transmission m...

Embodiment 3

[0042] In the process of transformer stacking, some transformers need to have a stepping amount. In order to meet this requirement, on the basis of Embodiment 2, a third lead screw and nut pair 33 is also provided on the second stacking frame 23. The third The screw nut pair 33 is driven by a servo motor.

[0043] In this embodiment, on the frame 15, the first guide rail 24 and the second guide rail 25 are provided in parallel on both sides of the first servo electric slide table 17, and the third guide rail 26 and the second guide rail 26 are provided in parallel on both sides of the second servo electric slide table 21. Four guide rails 27, these four guide rails are auxiliary load-bearing rolling guide rail pairs.

[0044] Material receiving output device 7 is made up of electromagnetic frock, idler roller and chain that are located at the electromagnetic frock below. The electromagnetic tooling is used to bind the iron core, and the roller and chain are used to move out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com