Super resolution reflecting film arrangement

A super-resolution and reflective film technology, applied in the field of optical storage, to achieve the effect of simple film structure, simple process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

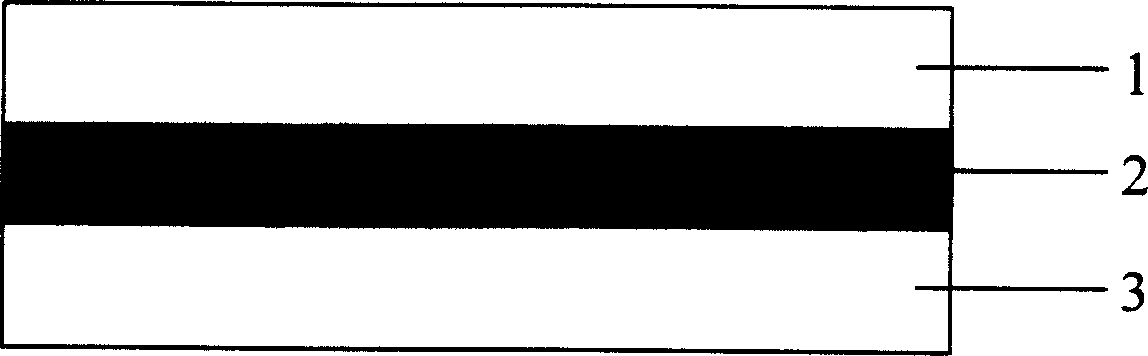

[0018] The structure of the super-resolution reflective film of the present invention is as follows figure 1 As shown, a protective layer 1, a super-resolution reflective film 2 and a protective layer 3 are included. The protective layer 1 and the protective layer 3 are used to prevent the super-resolution reflective film 2 from being damaged or oxidized, and the super-resolution reflective film 2 is used to read out the super-resolution information recording point.

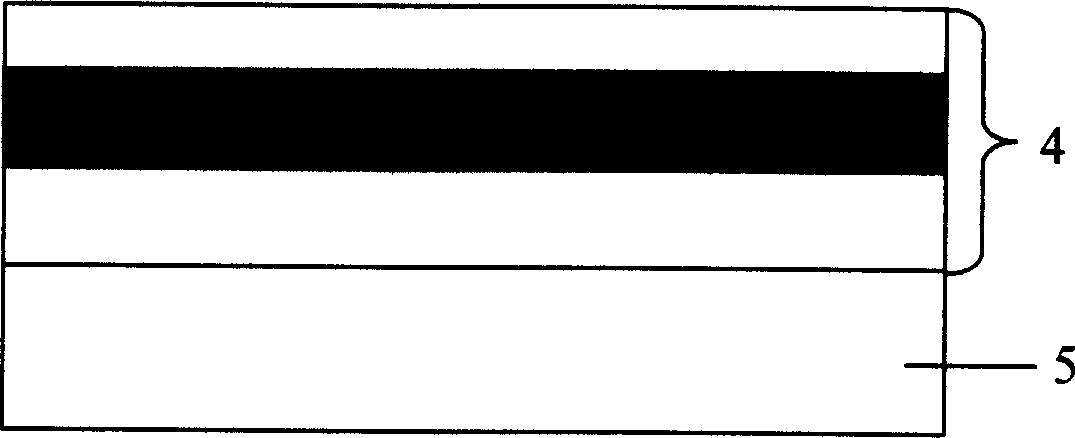

[0019] The protective layer 1 and the protective layer 3 in the present invention are both composed of silicon nitride with a thickness of 50-100 nm, and the super-resolution reflective film 2 is composed of antimony (Sb) or silicon (Si) or titanium (Ti) with a thickness of 5-50 nm , Take the value according to the specific situation of the implementation. The protective layer 1, the super-resolution reflective film 2 and the protective layer 3 jointly form the super-resolution reflective film structure 4, see figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com