Stone-wood composite base engineered flooring

一种复合基底、木地板的技术,应用在基于石-木复合材料的复合地板领域,能够解决破坏地板结构和整体外观等问题,达到加快安装过程的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

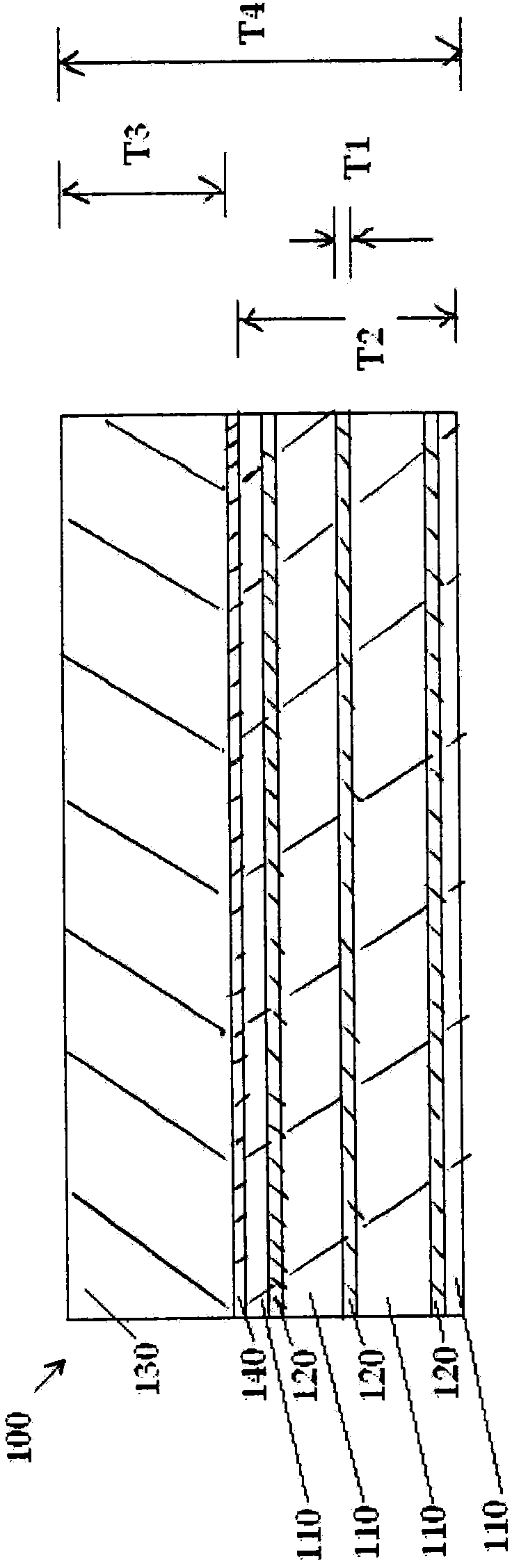

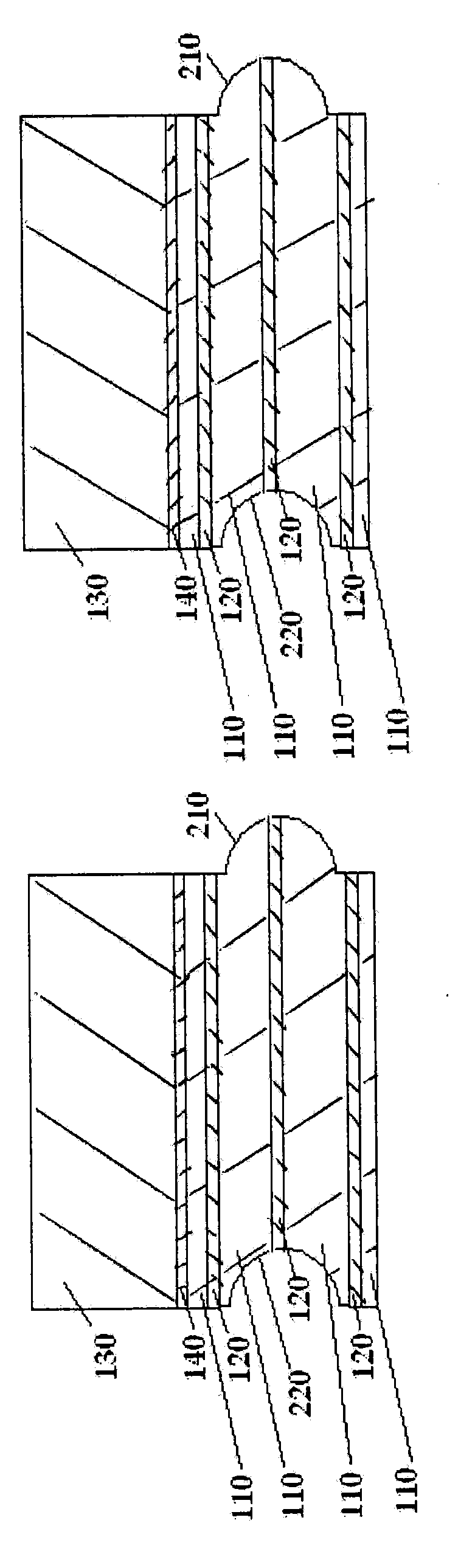

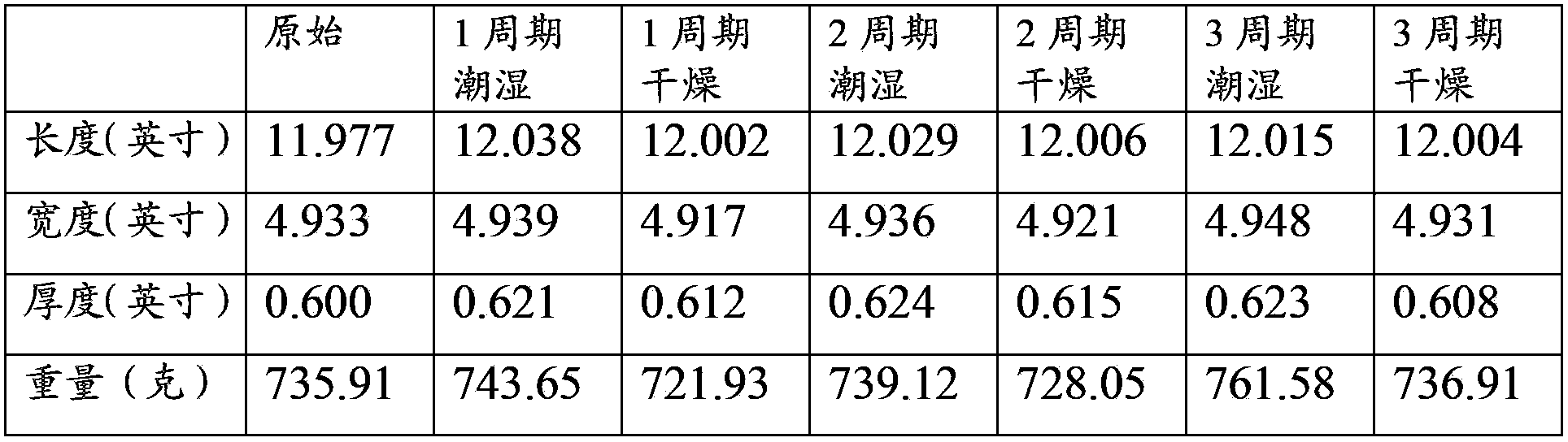

[0023] exist figure 1 A partial cross-sectional view of a composite wood flooring 100 according to the present invention is shown in . The floor 100 has a base layer 110 of stone-wood composite material. Preferably, the stone-wood composite comprises: MgO; wood particles (such as shavings, pulp or powder); MgCl 2 ; 2 o 3 ;H 3 PO 4 ;FeSO 4 . The base layer 110 absorbs moisture, moisture, and / or heat from its environment, which is then retained within the air pockets formed throughout the base layer. Despite the moisture and moisture retaining properties of the base layer, its stone crystal composition will never become moldy or develop a musty smell. As the temperature and / or environment changes, the substrate layer releases moisture, moisture and / or heat to the surrounding environment, or absorbs moisture, moisture and / or heat from the surrounding environment. The top wood veneer layer 130 remains substantially free from moisture, humidity and / or heat because the adhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com