Gas flow measuring device and method based on ultrasonic bypass flow principle

A gas flow and ultrasonic technology, which is applied in the field of gas flow detection and the measurement of new measuring instruments, can solve the problems of decreased measurement accuracy, waterlogging of ultrasonic probes, test failure, etc., and achieves reduced requirements for uniformity of flow field and uniformity of flow field. Low requirements and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

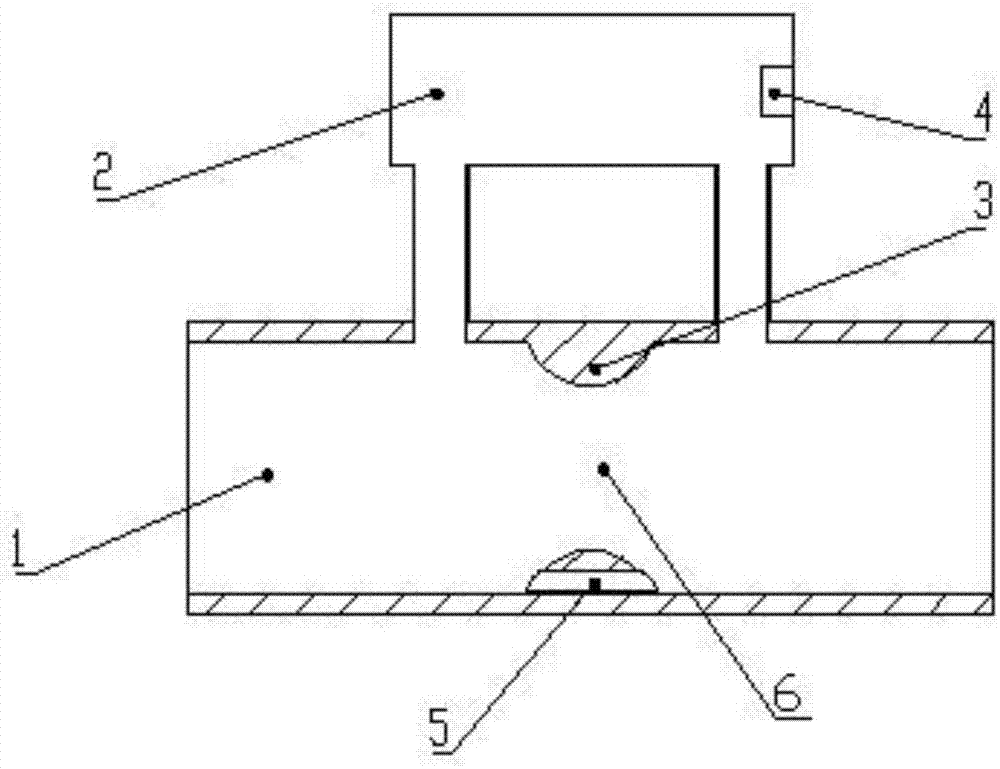

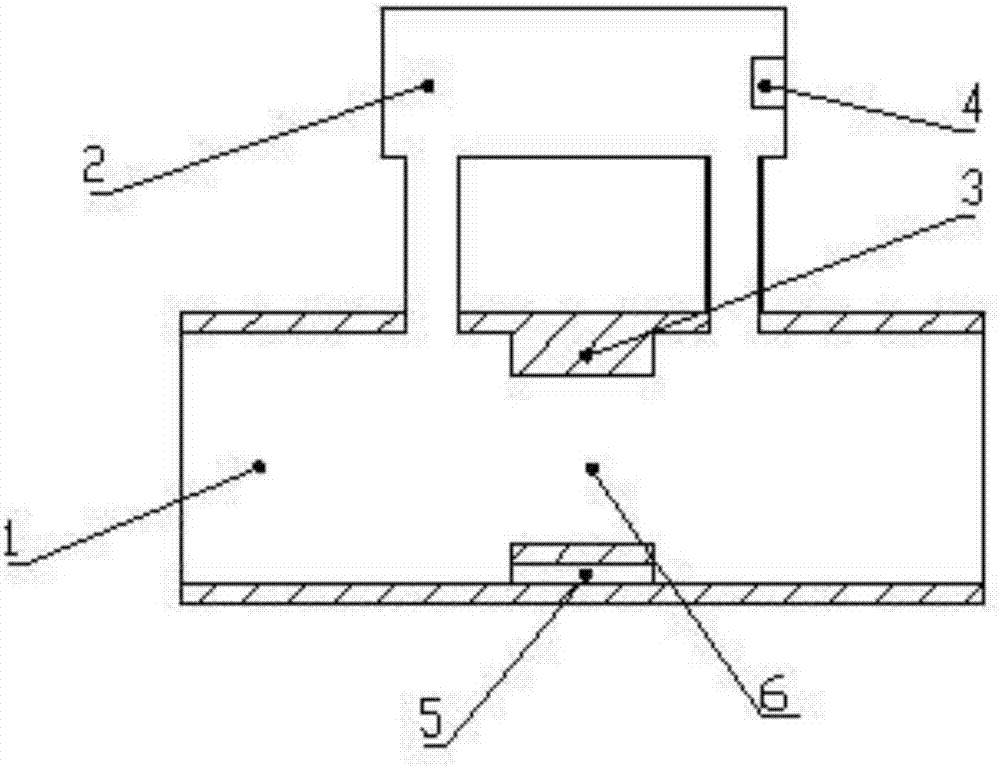

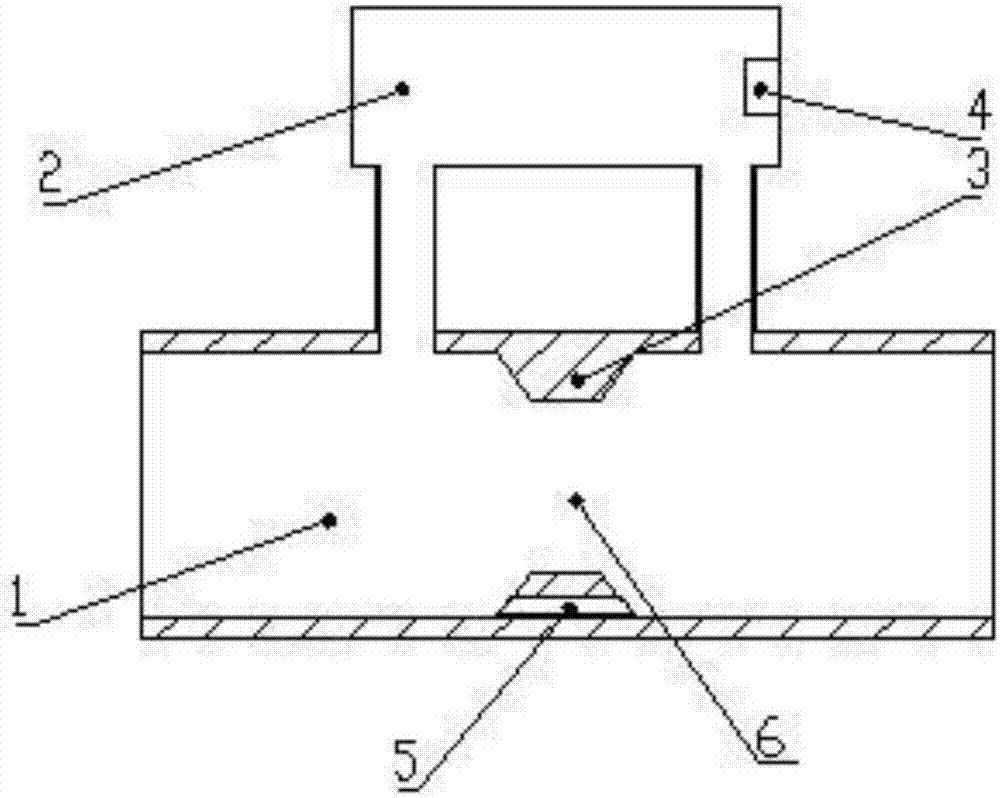

[0045] A gas flow detection device based on the principle of ultrasonic side flow, including a main pipeline 1 and a side flow pipeline 2, the main pipeline 1 communicates with the side flow pipeline 2, the side flow pipeline 2 is located on one side or the upper part of the main pipeline 1, along the The inner wall of the main pipe 1 is provided with two flow blocking elements 3 symmetrically up and down, and the side flow pipe 2 is provided with an ultrasonic sensor 4. The main pipe 1, the side flow pipe 2 and the flow blocking elements 3 together form a detection airway.

[0046] Two arc-shaped or square or trapezoidal baffles are axially arranged on the inner side of the main pipe 1, as attached figure 1 -3 shown.

[0047] Drain holes or grooves 5 are opened at the baffle 3 at the bottom of the main pipeline 1, as shown in A, B, C, and D in the accompanying drawing 8. One drainage hole or groove can be provided, and E and F can also be provided in the accompanying drawings...

Embodiment 2

[0066] A gas flow detection device based on the principle of ultrasonic side flow, including a main pipeline 1 and a side flow pipeline 2, the main pipeline 1 communicates with the side flow pipeline 2, the side flow pipeline 2 is located on one side or the upper part of the main pipeline 1, along the The inner wall of the main pipe 1 is provided with two flow blocking elements 3 symmetrically up and down, and the side flow pipe 2 is provided with an ultrasonic sensor 4. The main pipe 1, the side flow pipe 2 and the flow blocking elements 3 together form a detection airway.

[0067] Two arc-shaped or square or trapezoidal baffles are axially arranged on the inner side of the main pipe 1, as attached figure 1 -3 shown.

[0068] Ultrasonic sensor 4 can be set as shown in accompanying drawing 7: A: direct-ray type, B: X type (0 ° < θ < 180 °), C: V type (0 ° < θ < 90 °), D: W Type (0°<θ<90°).

[0069] The measurement steps are:

[0070] A. Through the bypass pipeline 2 and the...

Embodiment 3

[0085] as attached Figure 4 , 5 As shown: part of the side flow pipe 2 is used as a flow blocking element 3 and is arranged in the main pipe 1 , and an ultrasonic sensor 4 is arranged in the side flow pipe 2 .

[0086] as attached Image 6 As shown: the side flow pipeline 2 is located on one side of the main pipeline 1, and several densely arranged flow blocking elements 3 are arranged along the parallel direction of the airflow of the main pipeline 1. The flow blocking elements 3 are several small pipes with open ends, as shown in the attached Shown in A and B of Fig. 9;

[0087] The spoiler 3 can also be arranged in a comb shape, as shown in C and D of FIG. 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com