Continuous oxidation system and method for phi 3mm-10mm titanium alloy wires

An oxidation system, titanium alloy technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of uneven and insufficient oxidation of titanium alloy wires, and achieve the requirements of reducing uniformity and liberation. human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

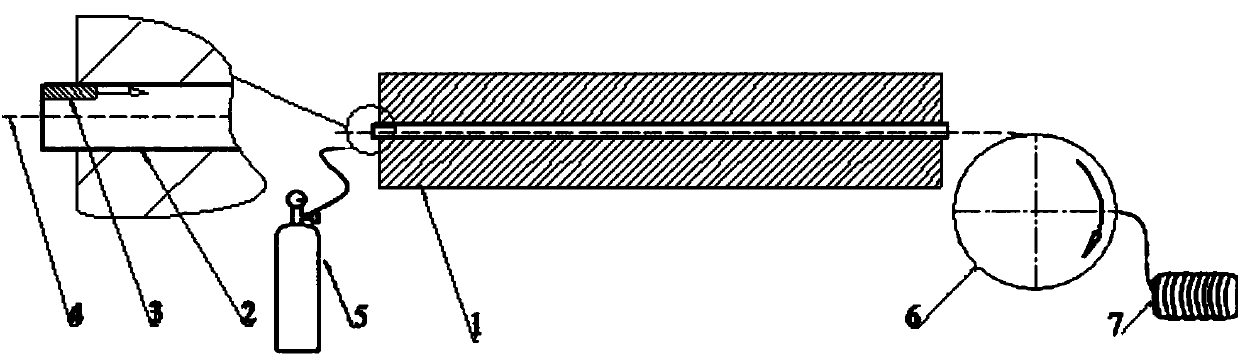

[0037] Use this system to continuously oxidize the Ti-25Nb-15Zr-1.5Al titanium alloy wire Φ8.0 billet, adopt a tubular heating furnace 1 with an effective working length of 4.8m, select a heating tube 2 with a diameter of 80mm, and set the tube The furnace temperature of the heating furnace 1 is 780℃. When the temperature is displayed on the meter, turn on the air supply device 3, let in air, adjust the air supply pressure to 0.05MPa, and thread the Φ8.0 diameter Ti-25Nb-15Zr-1.5Al wire into the tube In the heating furnace 1, the head of the wire 4 to be oxidized is fixed on the receiving turntable 6, the switch of the motor 7 connected to the receiving turntable 6 is turned on, and the rotation speed is set to 2.4m / min, and the wire is heated at a constant speed. 2. After all the wires have passed through the heating tube 2, the wires are removed from the receiving tray, the head and the tail are exchanged, and the above process is repeated once to achieve a uniform oxidation e...

Embodiment 2

[0039] Use this system to continuously oxidize the Ti-6Al-4V titanium alloy wire Φ4.0 billet: adopt a tubular heating furnace 1 with an effective working length of 3.6m, select a heating tube 2 with a diameter of 50mm, and set the tubular heating furnace 1 The furnace temperature is 850℃. After the meter displays the temperature, turn on the air supply device 3, feed in air, adjust the air supply pressure to 0.03MPa, and pass the Φ4.0 diameter Ti-6Al-4V wire into the tubular heating furnace 1, and fix it in Receiving turntable 6. Turn on the switch of the motor 7 connected to the receiving turntable 6, set the rotation speed to 6.4m / min, and the wire passes through the heating tube 2 at a constant speed. After all the wires have passed through the heating tube, remove the wires from the receiving tray. After observation and testing, the continuous oxidation of Ti-6Al-4V titanium alloy wire Φ4.0 billet has uniform surface color, natural transition, uniform oxide layer thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com