Detection method for rapid determination of melt index and molecular weight of fiber-type polypropylene special-purpose material

A melting index and detection method technology, applied in the chemical industry, can solve the problems of waste liquid, such as great environmental impact, high operation requirements, and non-representation, and achieve the effects of low sample uniformity requirements, fast method, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

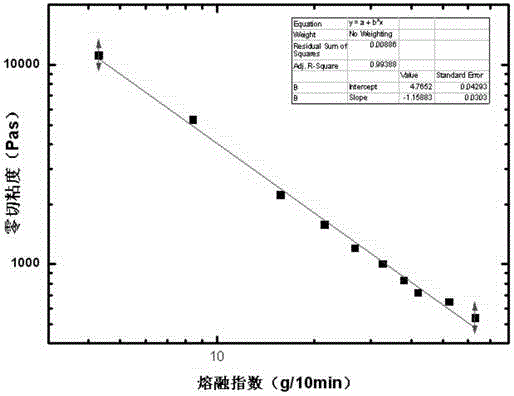

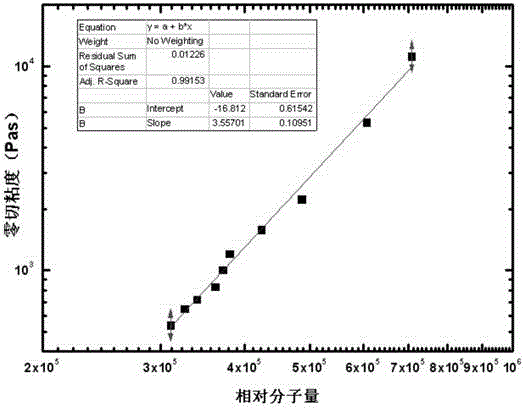

Embodiment 1

[0046] Use a mold to place a granular sample of fiber-type polypropylene special material with known weight-average molecular weight and melt index on a hot press, melt it at 180°C for 3 minutes, then apply a pressure of 4Mpa and continue hot pressing for 1 minute, and press to obtain Use the test sample; place the sample on a flat fixture with a diameter of 20mm in a strain-controlled rheometer. The applied detection frequency range is 10 -7 -628rad / s, set the temperature to 180°C, apply 5% strain, set the detection frequency range to 0.01-100rad / s, take 3 data points for each order of magnitude in logarithmic mode, set the integration time to 1 cycle, and measure Get the exponential scaling relationship between the zero-shear viscosity characteristic value and the melt index (MI) of fiber-type polypropylene special material, see figure 1 , the calculated pre-exponential factor is 5.75×10 4 , the exponent is -1.16, namely: η 0 =5.75×10 4 MI -1.16 ; Zero-shear viscosity a...

Embodiment 2

[0049] Use a mold to place a granular sample of fiber-type polypropylene special material with known weight-average molecular weight and melt index on a hot press, melt it at 180°C for 2 minutes, then apply a pressure of 3Mpa and continue hot pressing for 1 minute, and press to obtain Use the test sample; place the sample on a flat fixture with a diameter of 15mm in a strain-controlled rheometer. The applied detection frequency range is 10 -7 -628rad / s, set the temperature to 180°C, apply a strain of 1%, set the detection frequency range to 0.001-100rad / s, take 3 data points for each order of magnitude in logarithmic mode, set the integration time to 1 cycle, and measure The exponential scaling relationship between the zero-shear viscosity characteristic value and the melt index (MI) of fiber-type polypropylene special material is: η 0 =7.55×10 4 MI -1.21 ; Zero-shear viscosity and fiber-type polypropylene special material weight average molecular weight (M w ) The exponen...

Embodiment 3

[0052] Use a mold to place a granular sample of fiber-type polypropylene special material with known weight-average molecular weight and melt index on a hot press, melt it at 190°C for 3 minutes, then apply a pressure of 5Mpa and continue hot pressing for 2 minutes, and press to obtain Use a test piece; place the piece on a flat fixture of a strain-controlled rheometer with a diameter of 25mm. The applied detection frequency range is 10 -7 -628rad / s, set the temperature to 200°C, apply 8% strain, set the detection frequency range to 0.01-600rad / s, take 5 data points for each order of magnitude in logarithmic mode, set the integration time to 2 cycles, and measure The exponential scaling relationship between the zero-shear viscosity characteristic value and the melt index (MI) of fiber-type polypropylene special material is: η 0 =6.97×10 4 MI -1.23 ; Zero-shear viscosity and fiber-type polypropylene special material weight average molecular weight (M w ) has an exponential ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com