Silicon/carbon composite, silicon alloy/carbon composite, and methods for producing the same

A technology of carbon composites and silicon alloys, which is applied in the direction of carbon silicon compound conductors, hybrid/electric double layer capacitors, hybrid capacitors, etc., can solve problems such as non-coating, and achieve excellent charge-discharge cycle characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Exemplary embodiments of the present invention are described in detail below. It should be noted that the present invention is not limited to the following exemplary embodiments. It should be understood that the present invention includes various modifications that may be made to the following exemplary embodiments without departing from the scope of the present invention.

[0090] 1. Methods for preparing silicon / carbon composites and silicon alloy / carbon composites

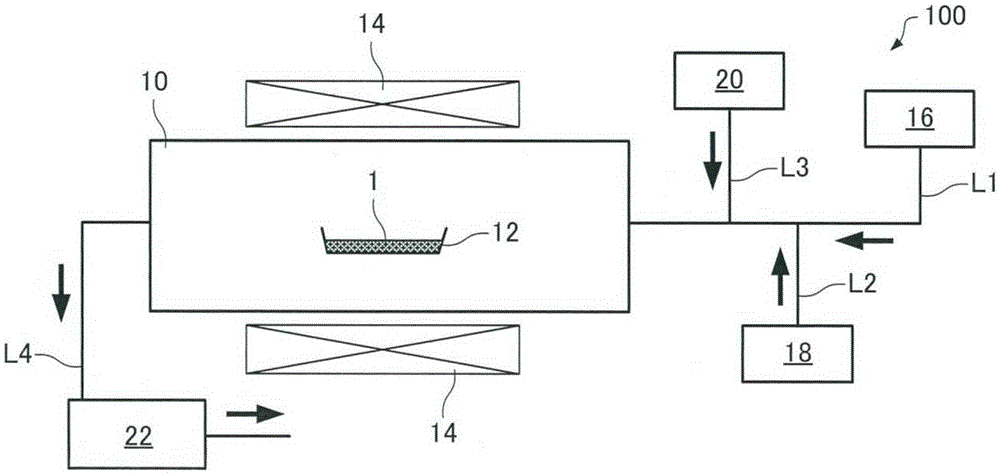

[0091] A method of preparing a silicon / carbon composite and a silicon alloy / carbon composite according to an embodiment of the present invention forms a CVD film on a surface of a conductive carbon material using a CVD film forming apparatus. The structure of a CVD thin film forming apparatus usable in connection with an embodiment of the present invention, and a method of producing a silicon / carbon composite and a silicon alloy / carbon composite according to an embodiment of the present invention are seq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com