Nonaqueous electrolyte secondary battery

A non-aqueous electrolyte and secondary battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of structural deterioration of positive active materials, electrolyte decomposition, etc., and achieve good charge-discharge cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

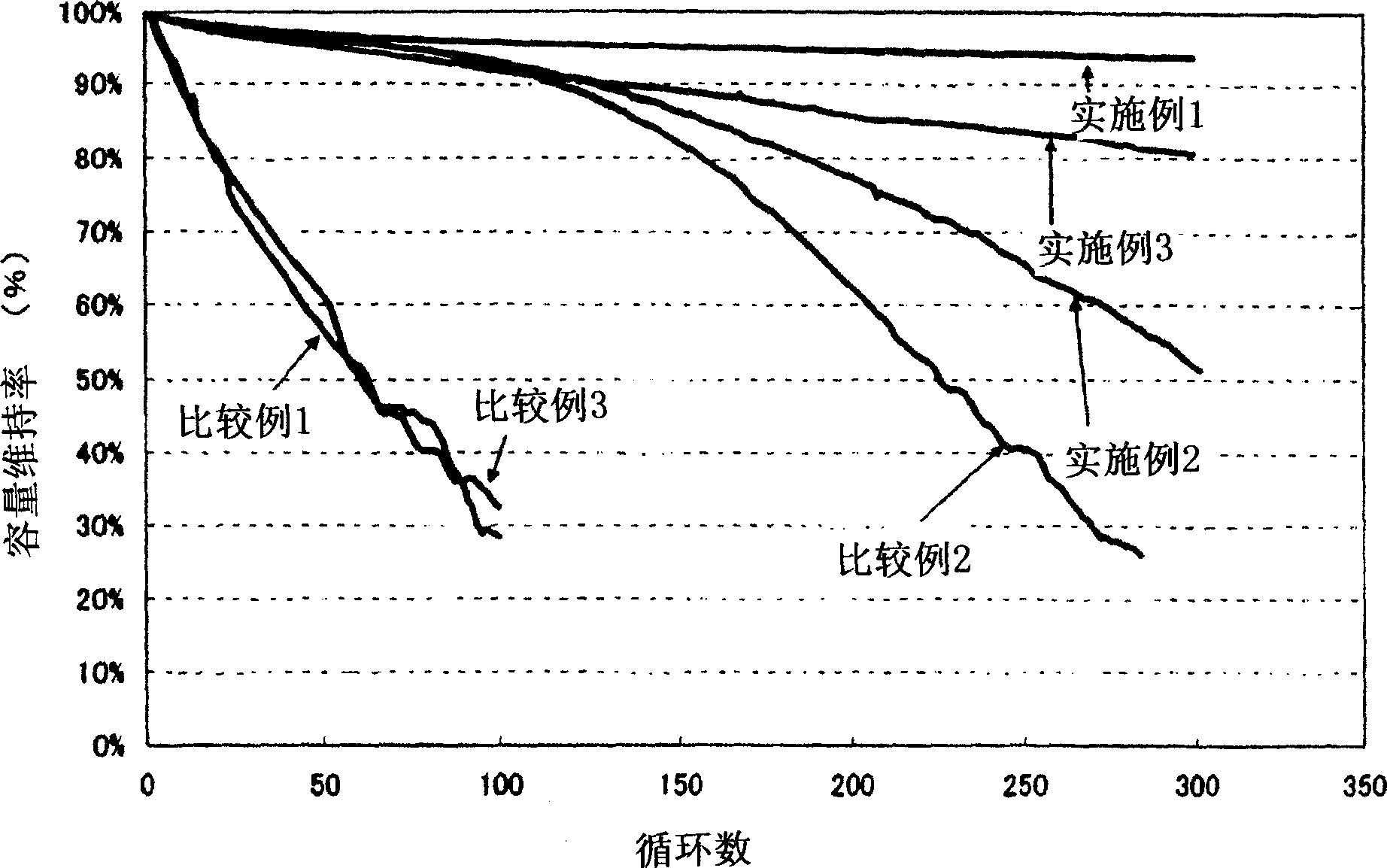

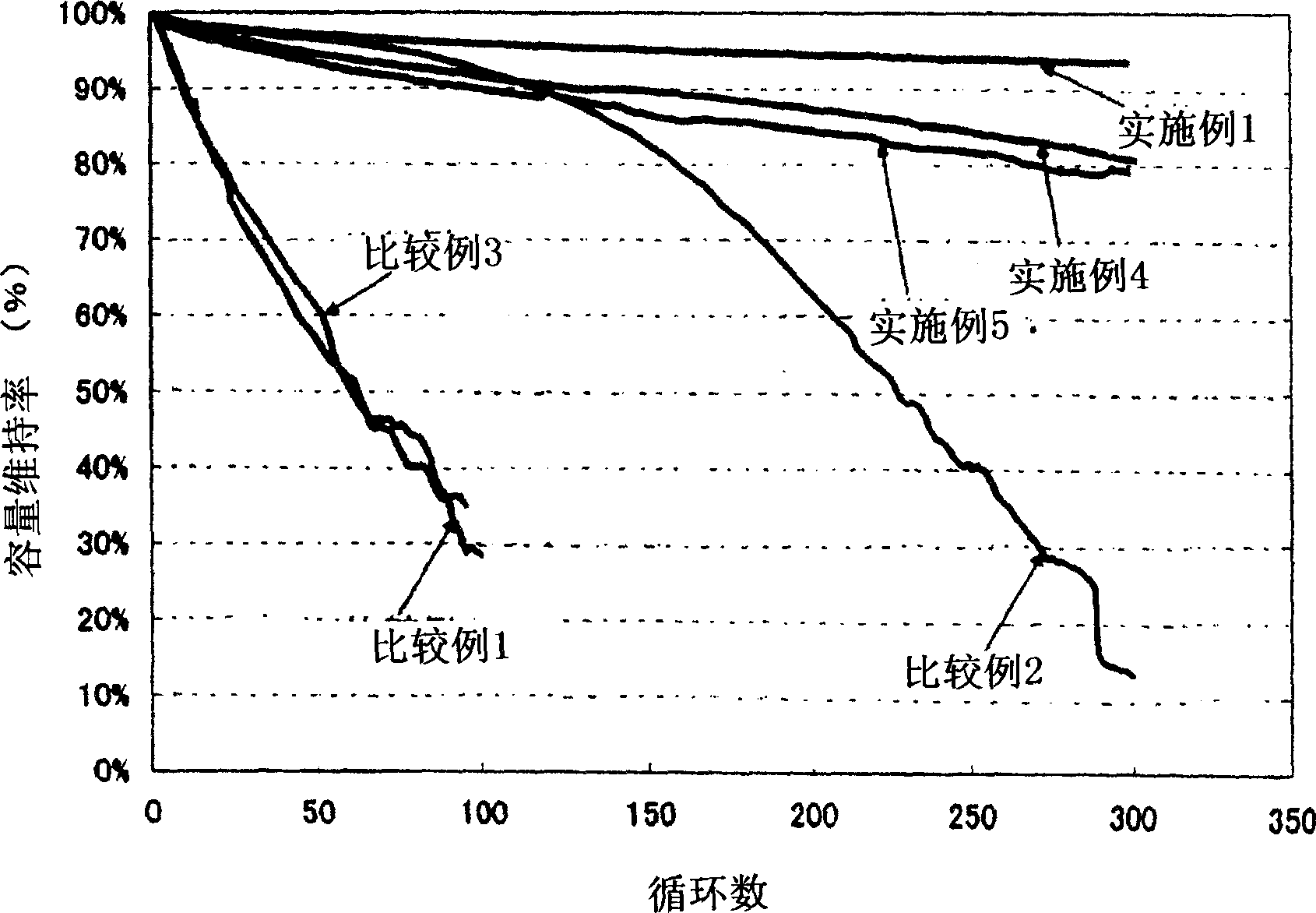

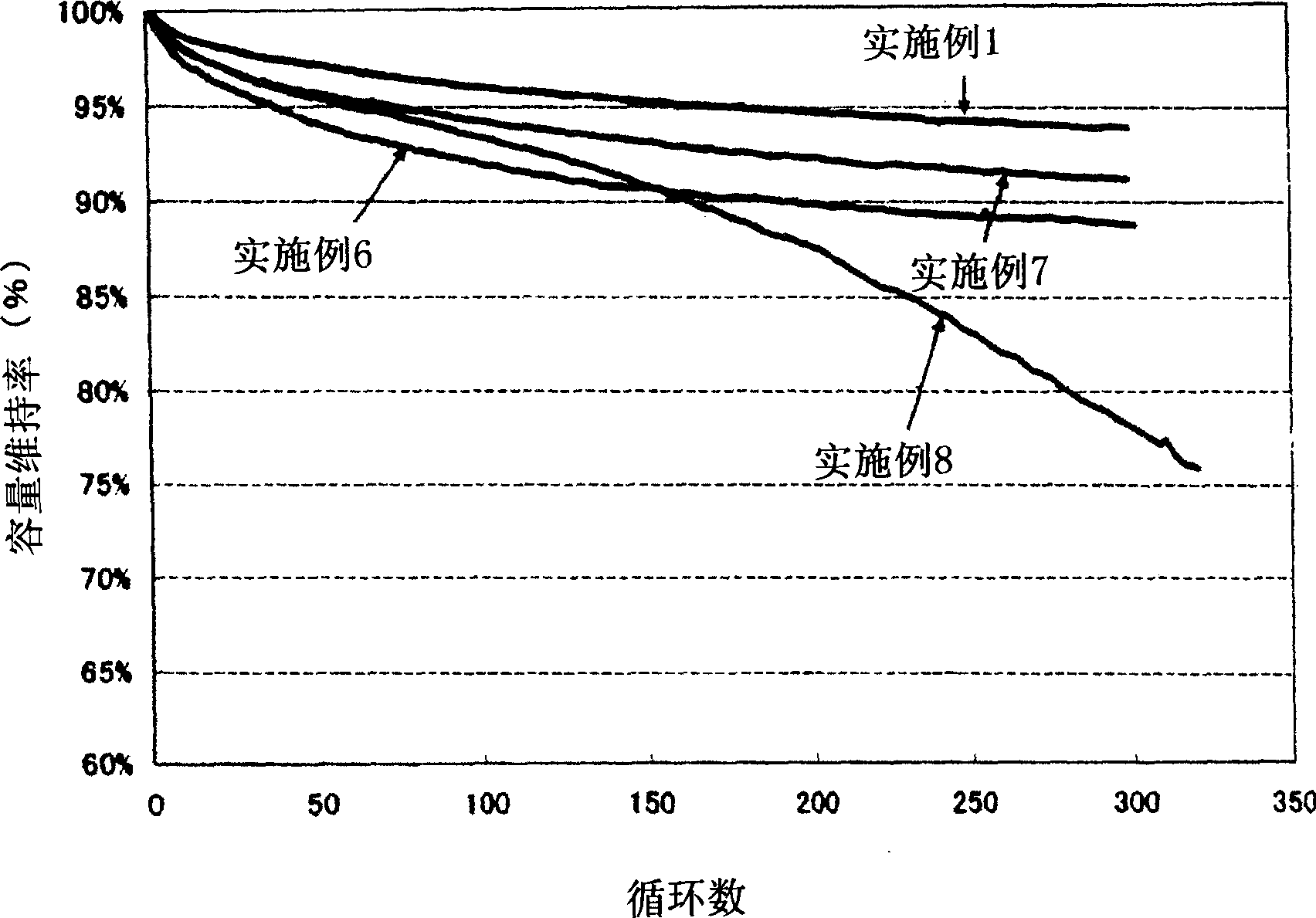

Embodiment 1

[0050] [Production of positive electrode active material]

[0051] Will Li 2 CO 3 、Co 3 o 4 , ZrO 2 and MgO according to the molar ratio of Li: Co: Zr: Mg of 1: 0.99: 0.005: 0.005 in the Ishikawa-type grinding and stirring mortar, heat treatment at 850 ° C for 24 hours under the air atmosphere, and then carry out Pulverized, thus obtained the average particle size of 13.9μm, BET specific surface area of 0.4m 2 / g of lithium transition metal oxide.

[0052] [making of positive electrode]

[0053] The positive electrode active material obtained above, carbon as a conductive agent, and polyvinylidene fluoride as a binder are added to N-methyl-2-pyrrolidone in a weight ratio of 90:5:5, and kneaded , to make positive electrode slurry. The prepared slurry was coated on an aluminum foil as a current collector, dried, and then rolled using a calender roll, and a current collecting sheet was attached to form a positive electrode.

[0054] [Production of Negative Electrode] ...

Embodiment 2

[0062] In the production of positive electrode active materials, in addition to Li 2 CO 3 、Co 3 o 4 , ZrO 2 and MgO according to the molar ratio of Li: Co: Zr: Mg being 1: 0.99: 0.0075: 0.0025 except that the molar ratio is mixed, all the other are made positive electrode active material in the same way as in Example 1, adopt this positive electrode active material to make non-aqueous electrolyte secondary Battery A2. The average particle size of the obtained positive electrode active material was 14.0 μm, and the specific surface area of BET was 0.39 m 2 / g.

Embodiment 3

[0064] In the production of positive electrode active materials, in addition to Li 2 CO 3 、Co 3 o 4 , ZrO 2 and MgO according to the molar ratio of Li: Co: Zr: Mg being 1: 0.99: 0.0025: 0.0075 except that the molar ratio is mixed, all the other are made positive electrode active material in the same way as in Example 1, adopt this positive electrode active material to make non-aqueous electrolyte secondary Battery A3. The average particle size of the obtained positive electrode active material was 14.2 μm, and the specific surface area of BET was 0.32 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com