Fuel cell equipment and fuel cell energy system

A fuel cell and energy system technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problem of high energy consumption of heat tracing and heat preservation devices, and achieve the effect of less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

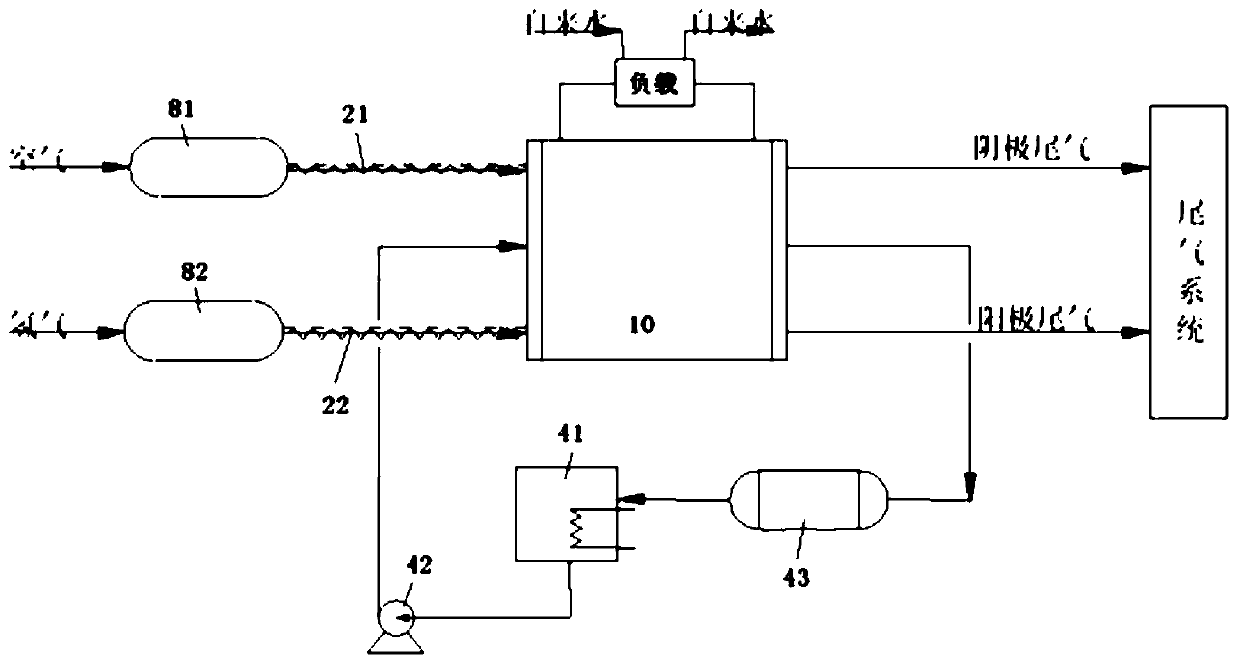

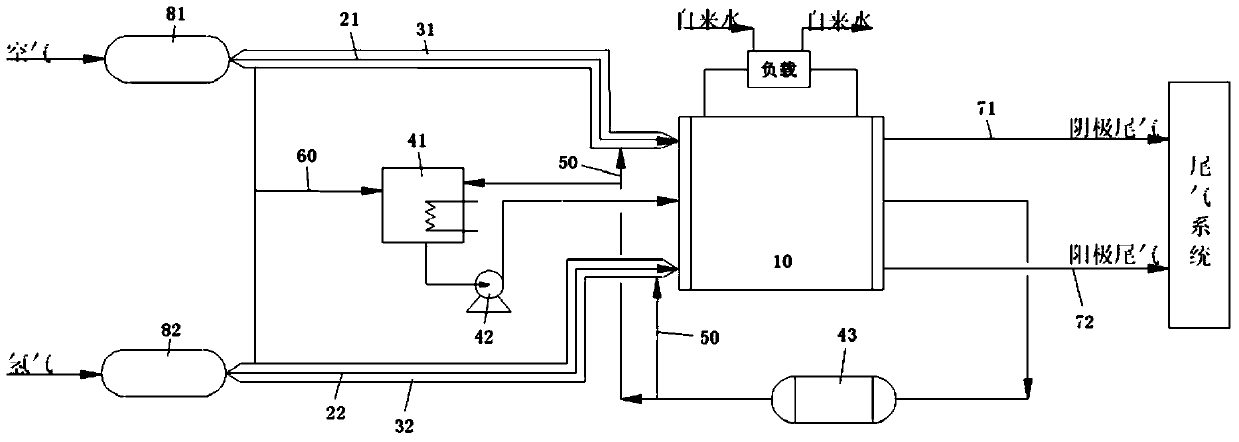

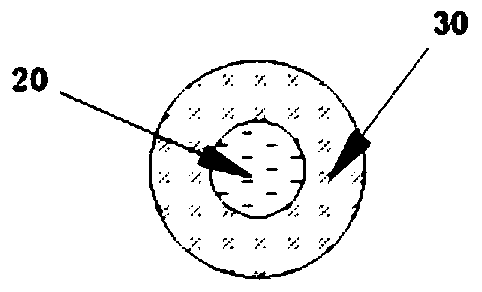

[0036] According to one aspect of the present invention, there is provided a fuel cell device, such as figure 2 In the illustrated embodiment, the fuel cell device includes: an electric stack 10; a reactant input pipe 20 connected to the electric stack 10 to input reactants; a heat exchange pipe 30 arranged in parallel with at least a part of the reactant input pipe 20, And the flow passage in the heat exchange tube 30 is separated from the flow passage in the reactant input pipe 20 by a partition; the first heat conduction part connects the electric stack 10 and the heat exchange pipe 30, so as to transfer the waste heat generated by the electric stack 10 to Heat exchange tube 30.

[0037] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com