Special connector for T contact of main line of urban and rural power network

A technology for power grids and main lines, which is applied in the direction of connecting/disconnecting connected parts, connecting devices, two-part connecting devices, etc., and can solve the problems of easy corrosion of control switch components and equipment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

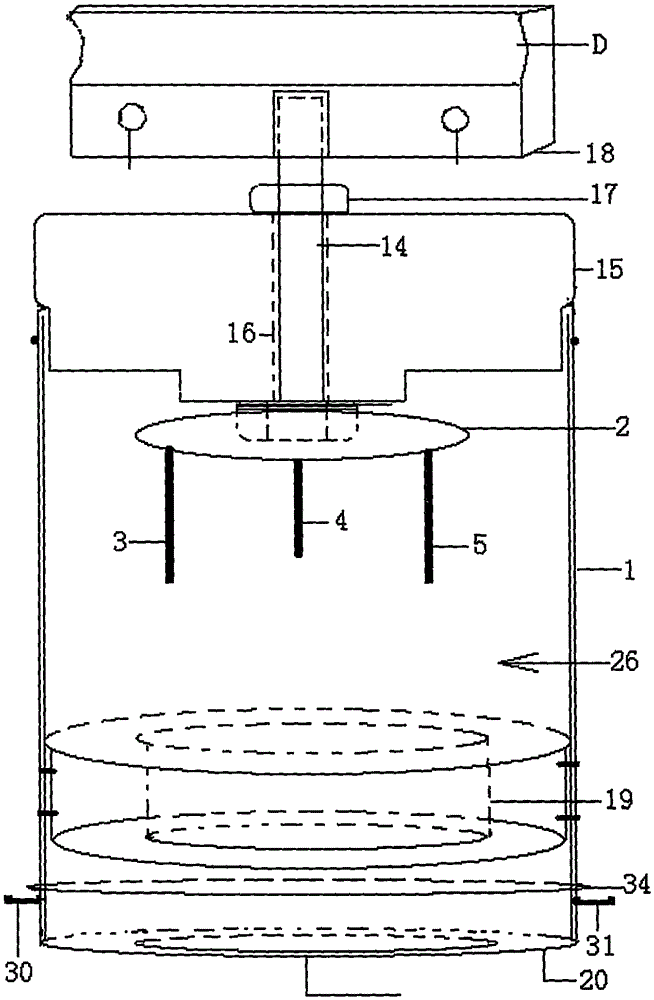

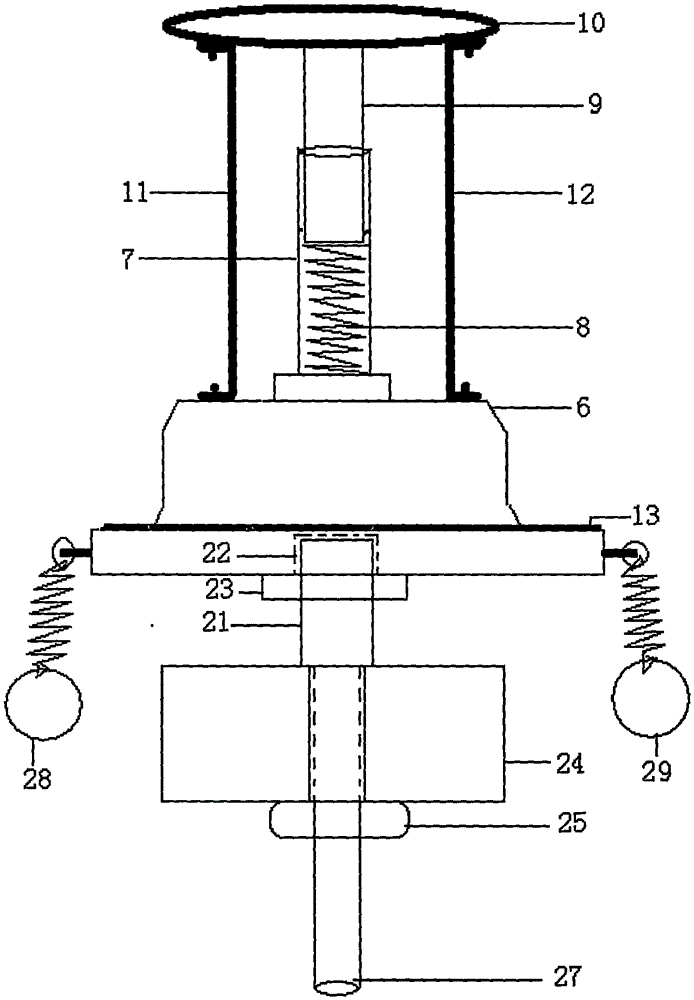

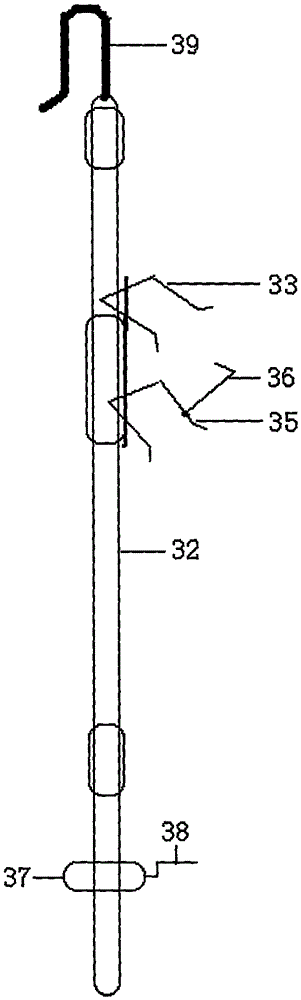

[0011] figure 1 , figure 2 Showing the structure of the present invention, a collector ring 2 is arranged in the sealed chamber 1 of the T-contact power contact, and a first conductive pile 3, a second conductive pile 4, and a third conductive pile 5 are arranged at the lower end of the collector ring 2, and the first conductive pile The lower part of the pile 3, the second conductive pile 4, and the third conductive pile 5 is provided with a conical load conductance head 6, and a circular puller 7 is arranged in the middle of the conical load conduction head 6, and a support spring 8 is arranged inside the circular puller 7 , the upper end of the support spring 8 is provided with a circular pull rod 9, the top of the circular pull rod 9 is provided with a circular electric conduction plate 10, the bottom side of the circular electric conduction plate 10 is provided with a first flexible connection telescopic wire 11, and the other side is provided with a second flexible conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com