Method for making 10KV heat-shrinkable three-core cross-linked polyethylene cable intermediate joint

A technology of cable intermediate joints and cross-linked polyethylene, which is applied in the direction of connecting/terminating cables, etc., can solve the problems that the personal safety of the staff cannot be guaranteed, and the power cables cannot work normally, so as to achieve outstanding substantive features and design principles Reliable, the effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The following embodiments are explanations of the present invention, but the present invention is not limited to the following embodiments.

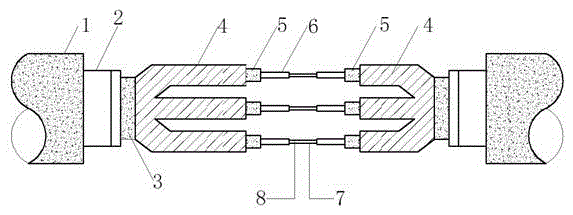

[0035] figure 1 A structural schematic diagram of cable stripping of the present invention is given.

[0036] This embodiment provides a method for manufacturing a 10kV heat-shrinkable three-core XLPE cable intermediate joint, including the following steps:

[0037] S1: Align and cut the cables. After removing the metal stress of the two cables for the intermediate joint, align the two cables and overlap them by 200-300mm. Determine the center of the intermediate joint and align the core wires of the cables. cut the two cables;

[0038] S2: Strip the outer sheath layer and armor, take the size of the outer sheath layer according to the specific demand, and strip the outer sheath layer to expose the armor....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com