Automatic cleaning device

An automatic cleaning and equipment technology, applied to poultry plucking machines, slaughtering, poultry processing, etc., can solve the problems of low hair removal efficiency, poor hair removal effect, and pollution of the environment, and achieve good hair removal effect, high hair removal efficiency, and less environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

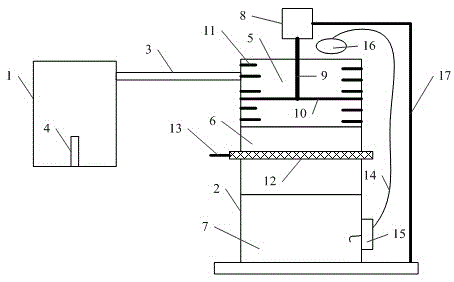

[0021] In Embodiment 1, an automatic cleaning device is provided, please refer to figure 1 , the equipment includes:

[0022] Water tank 1, cylinder 2, a transmission belt 3 is connected between the water tank and the cylinder, an electric heating tube 4 is arranged in the water tank, and the cylinder is successively a depilatory area 5 and a hair collection area from top to bottom. Area 6, water collection area 7, the bottom of the depilation area is provided with a pulley, the upper surface of the hair collection area is provided with a chute, the pulley is embedded in the chute, the depilation area and the hair collection area Sliding connection, such design can facilitate the high-speed rotation of the depilation area, the upper end of the depilation area is open, the lower end of the depilation area is a mesh structure, a motor 8 is arranged above the cylinder, and the rotating shaft 9 of the motor passes through The connecting rod 10 is connected to the inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com