High-efficiency unhairing machine used for slaughtering assembly lines

An assembly line and hair removal machine technology, applied in slaughtering, poultry depilation machines, applications, etc., can solve problems such as difficult to achieve mass production, not well adapted to modern factories, etc., to improve efficiency, improve efficiency, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

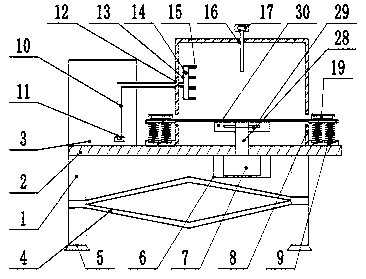

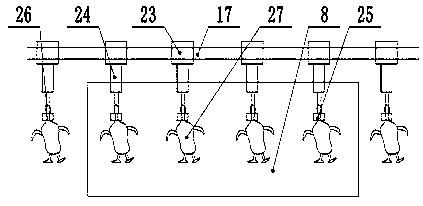

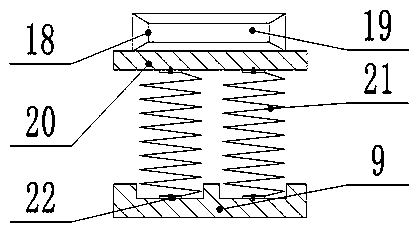

[0021] see figure 1 , a high-efficiency hair removal machine used in a slaughter line, including: a column 1, a working chamber 8 and a connecting rod 24, the column 1 is fixedly installed above the ground, and a column foot 5 is installed below the column 1, and the column ground The foot 5 is made of rubber, which has the effect of cushioning and shock absorption, and reduces the noise generated during use. The middle part of the column 1 is provided with a column support rod 4, and the column support rod 4 is a stainless steel pipe. , to improve the ability of the equipment to withstand radial loads and improve stability, the upper end of the column 1 is fixedly installed with a support beam 2, the support beam 2 has a 50*50 square tube to form a support beam, and the outside of the support beam 2 is treated with anti-rust , to ensure the stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com