Connection back bar device for zipper production line

A production line and zipper technology, applied in the direction of application, sliding fastener components, fasteners, etc., can solve the problems affecting the processing quality of zippers and zipper scrapping, and achieve the effects of avoiding processing scrapping, ensuring processing quality, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

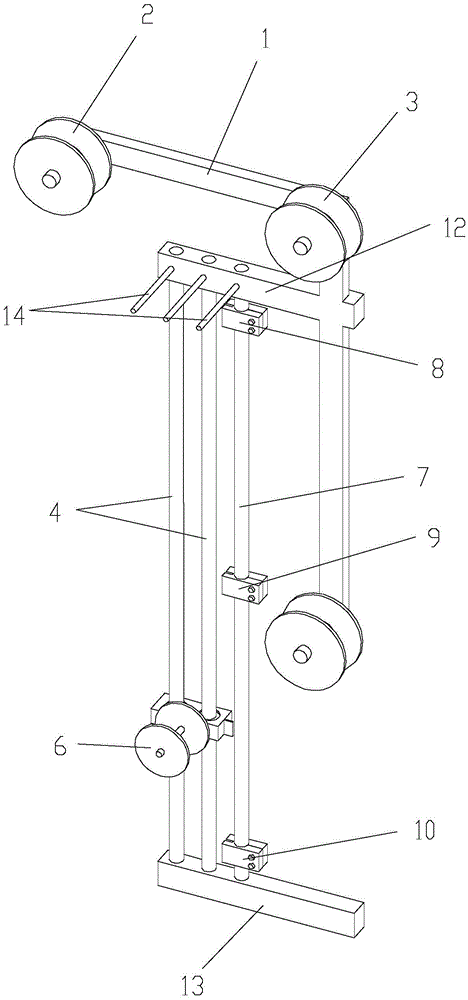

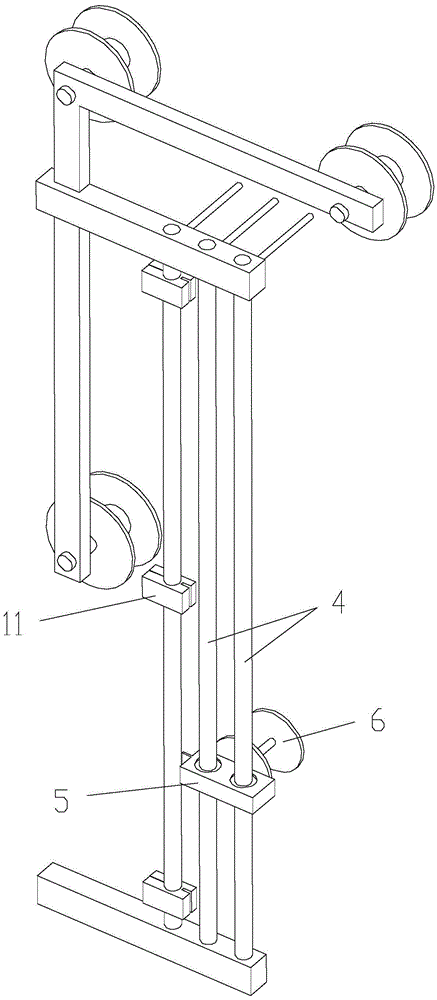

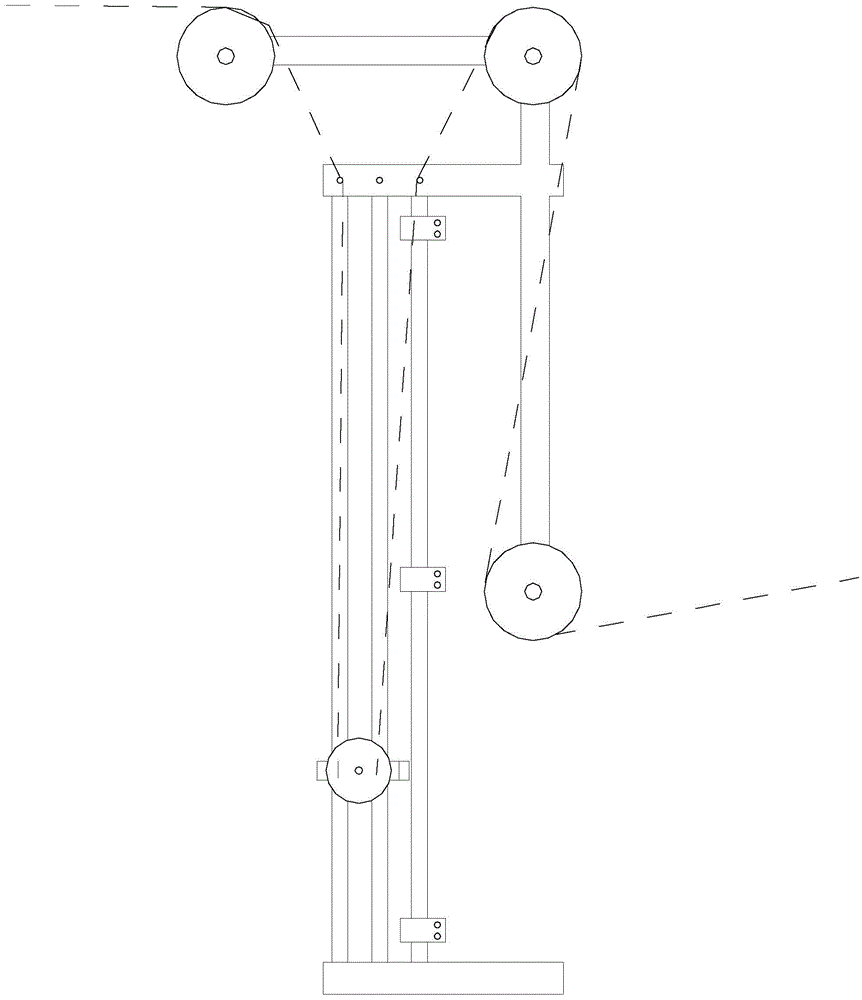

[0017] The present invention will be further described below in conjunction with accompanying drawing:

[0018] Referring to the accompanying drawings: the connecting back bar device used on the zipper production line in this embodiment includes a cross bar 1, and the left and right ends of the cross bar 1 are respectively equipped with an inlet guide wheel 2 for the zipper to be sent in and an out guide wheel for the zipper to be sent out. Wheel 3, guide rail 4 installed vertically between the guide wheel 2 and the guide wheel 3, the slide seat 5 is installed on the guide rail 4, the lifting guide wheel 6 is installed on the slide seat 5, and the side of the guide rail 4 is equipped with Upright bar 7, upright bar 7 is respectively installed with the emergency stop switch 8 that contacts with slide seat 5, delay switch 9, start switch 10 successively from top to bottom. The emergency stop switch 8, the delay switch 9, and the start switch 10 are respectively fixed on the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com