Upper discharge device of filtering tank

A drainage device and filter tank technology, applied in the feed/discharge device of the settling tank, chemical instruments and methods, separation methods, etc., can solve the problems of sedimentation, long time-consuming filtration, and reduced efficiency of solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

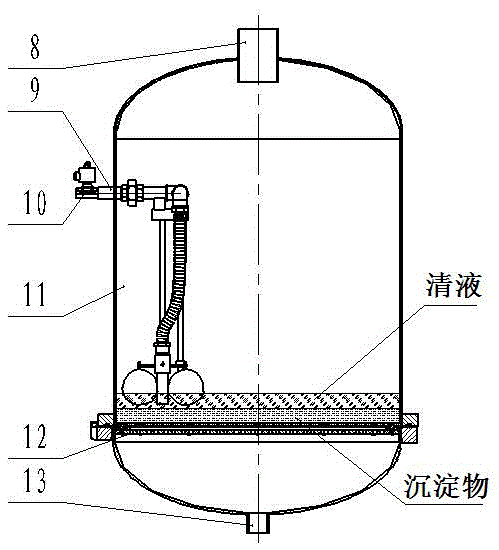

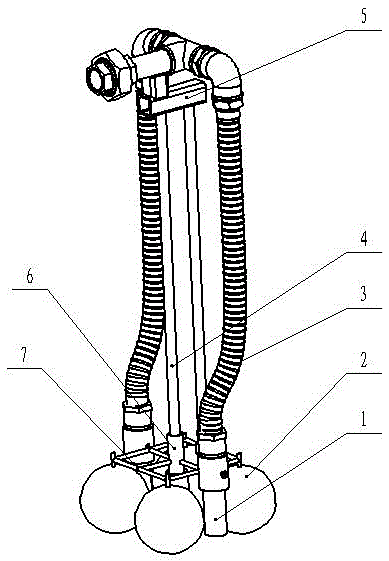

[0014] Embodiment 1: A drainage device on a filter tank, including a float, a connecting frame, a suction nozzle, a hose, a valve, and a tank body. The tank body is a closed container, and the floating ball, the connecting frame, the suction nozzle, and the hose are Set inside the tank, there are four floating balls fixed on the connecting frame and floating on the liquid surface, the suction nozzle is fixed on the connecting frame, one end of the suction nozzle is inserted into the liquid surface, and the other end is connected to the drain on the upper part of the tank through a hose The outlet is connected, a valve is installed at the drain, the guide rod that is placed vertically and passes through the guide ring is fixedly connected with the guide rod frame, the guide rod frame is fixed on the inner wall of the tank, and the guide ring is fixed on the connecting frame, so that Make the float and the connecting frame move up and down along the guide rod with the height of t...

Embodiment 2

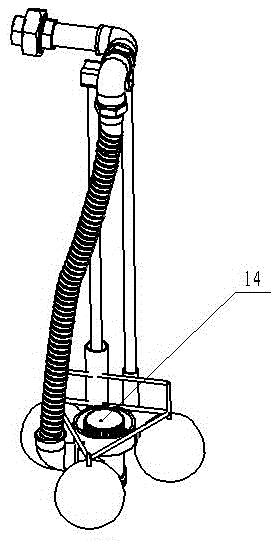

[0016] Embodiment 2: A drainage device on a filter tank, including a float, a connecting frame, a hose, a submersible pump, and a tank body. The tank body is a closed container, and the float ball, connecting frame, submersible pump, and hose are all arranged on Inside the tank, there are three floating balls fixed on the connecting frame and floating on the liquid surface. The submersible pump is fixed on the connecting frame. The suction end of the submersible pump is located below the liquid surface. The drain port of the tank is connected, the guide rod that is placed vertically and passes through the guide ring is fixedly connected with the guide rod frame, the guide rod frame is fixed on the inner wall of the tank, and the guide ring is fixed on the connecting frame, so that the floating ball and the connection The frame moves up and down along the guide rod with the height of the liquid level.

[0017] The liquid to be filtered is injected from the feed port of the tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com