Buffering type sterilizing and light-emitting cutting tool high in bonding strength

A combination of strength and cutting tool technology, applied in the field of cutting tools, can solve the problems of insufficient bonding strength between the blade and the tool body, poor strength and wear resistance, shortened service life of the blade, etc., to achieve high wear capacity, high strength and wear resistance Performance and service life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

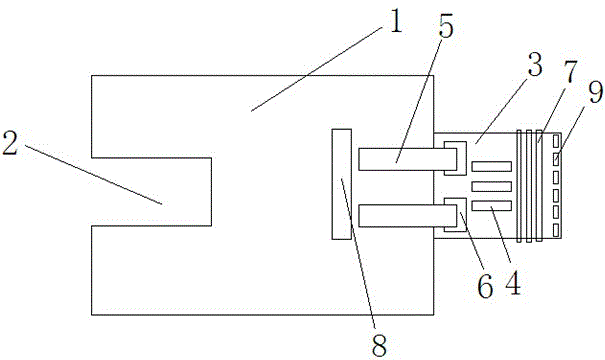

[0014] Such as figure 1 As shown, a buffer type sterilizing luminescent cutting tool with high bonding strength includes a tool body 1 and a blade 3, and a threaded hole 2 for connecting with a driving device is provided at the rear end of the tool body 1, and a threaded hole 2 is provided in the threaded hole There is an internal thread, and a blade 3 is arranged at the front end of the cutter body 1, and the blade 3 is made of tungsten-titanium-cobalt cemented carbide. The blade is made of YT05 / YT30 tungsten-titanium-cobalt cemented carbide. Three weight-reducing grooves 4 are arranged in the middle of the blade 3 , and the arrangement direction of the weight-reducing grooves 4 is perpendicular to the direction of the edge of the blade 3 . Two straps 5 are welded on the tool body 1, hooks are provided at the free ends of the straps 5, and two slots 6 are arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com