Manufacturing method of brake disc

A technology for a brake disc and preparation steps, which is applied in the field of brake disc casting, can solve the problems of increased labor, many sand mold manufacturing processes, and large dust in the foundry workshop, and achieves the effects of saving manpower, improving labor environment, and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

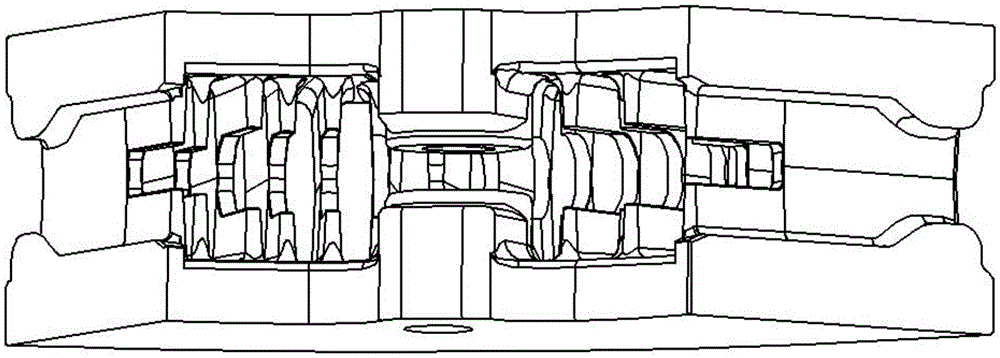

Image

Examples

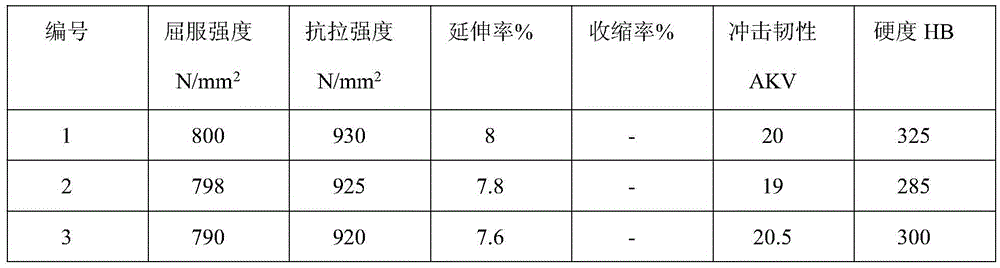

Embodiment 1

[0020] (1) First, the Bonnie No. 2 thermosetting resin is mixed with quartz sand to obtain the sand material for preparing the brake disc sand shell, and the usage amount of Bonnie No. 2 thermosetting resin is 1.6% of the weight of the quartz sand;

[0021] (2) Then put the sand material prepared in step (1) into the sand-shooting machine, heat the sand material to 150-155°C, and then sandblast the mold under a pressure of 5 atmospheres to obtain a sand with a brake disc cavity. The shell, the sand shell is naturally cooled for use, and the thickness of the sand shell is 40mm;

[0022] (3) Prepare the raw materials for the brake disc according to the following components by weight percentage: 0.20% carbon (C), 0.80% manganese (Mn), 0.5% silicon (Si), 1.25% chromium (Cr), molybdenum (Mo) 1.0%, nickel (Ni) 0.5%, vanadium (V) 0.32%, sulfur (S) 0.03%, phosphorus (P) 0.03%, and the balance is iron; then the raw materials are mixed and heated to 1000-1050°C, and then melted pouring...

Embodiment 2

[0025] (1) First, the Bonnie No. 2 thermosetting resin is mixed with quartz sand to obtain the sand material for preparing the brake disc sand shell, and the usage amount of the Bonnie No. 2 thermosetting resin is 1.8% of the weight of the quartz sand;

[0026] (2) Then put the sand material prepared in step (1) into the sand-shooting machine, heat the sand material to 155-160°C, and then sandblast the mold under a pressure of 6 atmospheres to obtain a sand with a brake disc cavity. The shell, the sand shell is naturally cooled for use, and the thickness of the sand shell is 45mm;

[0027] (3) Prepare the raw materials for the brake disc according to the following components by weight percentage: 0.25% carbon (C), 1.00% manganese (Mn), 0.55% silicon (Si), 1.30% chromium (Cr), molybdenum (Mo) 1.1%, nickel (Ni) 0.60%, vanadium (V) 0.30%, sulfur (S) 0.032%, phosphorus (P) 0.032%, and the balance is iron; then the raw materials are mixed and heated to 950-1250°C, and then melted ...

Embodiment 3

[0030] (1) First, the Bonnie No. 2 thermosetting resin is mixed with quartz sand to obtain the sand material for preparing the brake disc sand shell, and the usage amount of the Bonnie No. 2 thermosetting resin is 1.5% of the weight of the quartz sand;

[0031] (2) Then put the sand material prepared in step (1) into the sand-shooting machine, heat the sand material to 140-145°C, and then perform sandblasting molding under a pressure of 4.5 atmospheres to obtain a sand with a brake disc cavity. The shell, the sand shell is naturally cooled for use, and the thickness of the sand shell is 35mm;

[0032] (3) Prepare the raw materials for the brake disc according to the following components by weight percentage: 0.20% carbon (C), 0.65% manganese (Mn), 0.45% silicon (Si), 1.20% chromium (Cr), molybdenum (Mo) 1.0%, nickel (Ni) 0.65%, vanadium (V) 0.30%, sulfur (S) 0.030%, phosphorus (P) 0.030%, and the balance is iron; then the raw materials are mixed and heated to 950-1250°C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com