Gearbox rear shell drilling fixture and application method thereof

A drilling jig and rear casing technology, which is applied to the field of the rear casing drilling jig of a gearbox, can solve the problems of difficult control of processing accuracy, complex structure and shape, and difficult processing, and achieves improved drilling processing efficiency, loading and unloading maintenance. Convenience and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

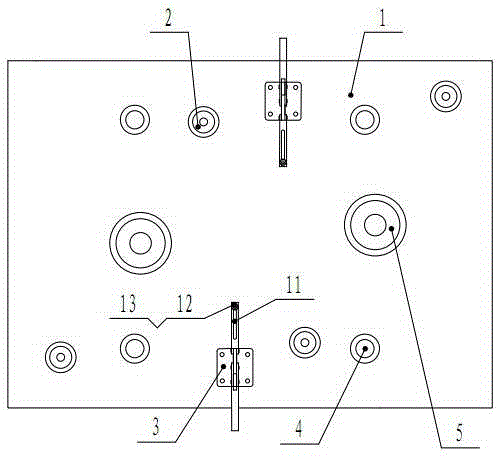

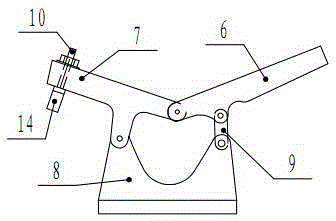

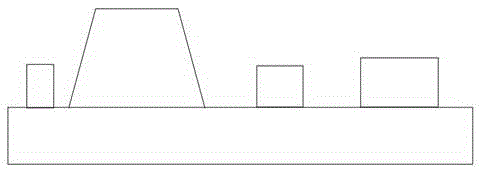

[0024] Embodiment 1: as Figure 1~Figure 4 As shown, a gear box rear case drilling jig includes a jig plate 1, two positioning pins 2 and a pressing device 3 for positioning parts are arranged on the jig plate 1, and the top of the positioning pin 2 is a ball head , two sets of the drilling jig are set on the same jig plate 1, and the jig plate 1 is provided with a countersunk screw hole 4, and the countersunk screw passes through the countersunk screw hole to connect with the T-shaped groove on the workbench, and the installation The dismantling is convenient and quick. In order to avoid damage to the tool during processing, a process hole 5 is also provided on the fixture plate 1 .

[0025] As a preferred technical solution, the above-mentioned positioning pin 2 is fixedly connected to the fixture plate 1 by screws, which is convenient and quick to install and easy to assemble and disassemble.

[0026] As a preferred technical solution, the above-mentioned pressing device 3...

Embodiment 2

[0027] Embodiment 2: A method for using a drilling jig for a gearbox rear case, comprising the following steps:

[0028] (1) Install the positioning pins on the fixture plate;

[0029] (2) Clean up the dust on the positioning pin;

[0030] (3) Place the part on the corresponding position on the clamp body for positioning;

[0031] (4) Fasten the upper part by the pressing device;

[0032] (5) Place the installed clamp body on the machine table for processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com