Rigidity-improved connecting rod type clamping structure

A connecting rod and holder technology, which is applied in the field of improving the rigid connecting rod clamping structure, can solve the problems of inaccurate insertion, slippage, discount of radioactive source visual positioning effect, etc., to ensure functional stability, simple and reliable structure, Effect of Reliability Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

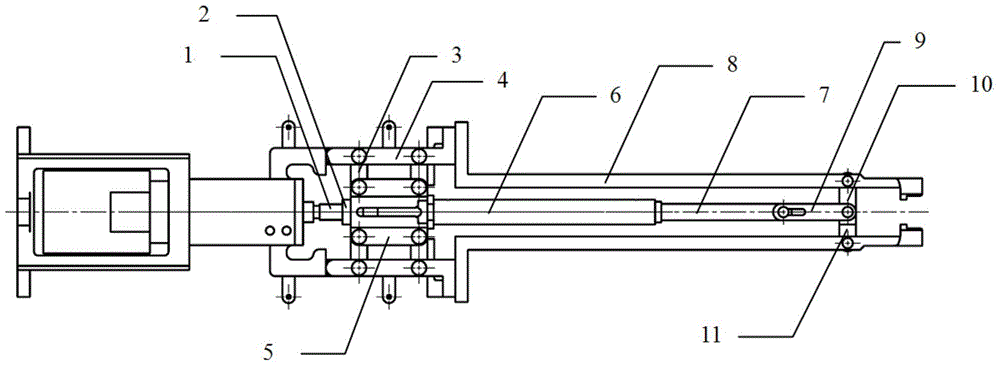

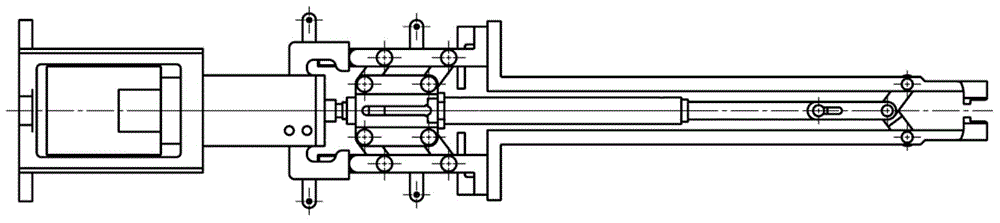

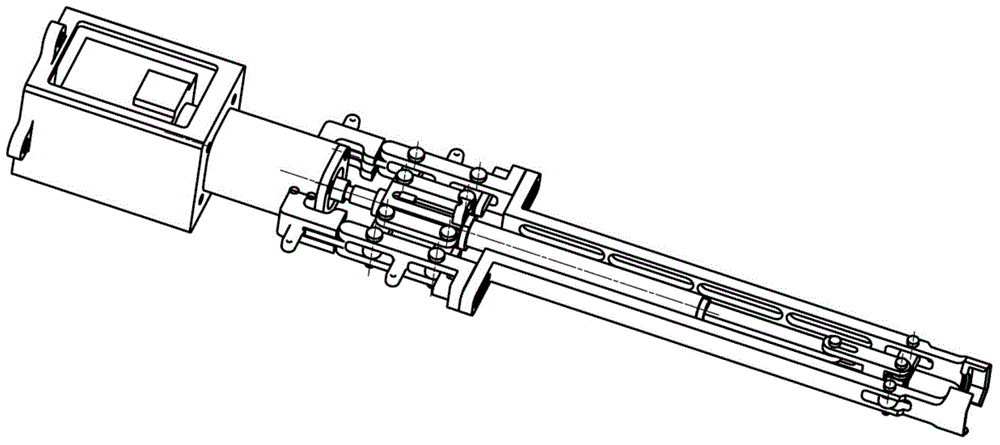

[0013] as attached figure 1 As shown, a multifunctional end gripper includes a palm 5, one end of the palm 5 is connected to a lead screw 1 through a lead screw nut 2, and the lead screw 1 is connected to the outside and controlled by an external device. The other end of the palm 5 is connected with the outer finger 8 and the inner finger bar 6, the outer finger 8 has two, these two outer fingers 8 and the inner finger bar 6 are parallel, and the inner finger bar 6 is arranged on two outer fingers. Refers to the middle of 8. When the leading screw 1 rotates, the palm 5 can convert the rotation of the leading screw 1 into clamping or loosening of the two outer fingers 8, and simultaneously control the extension or retraction of the inner finger rod 6. The front end of the inner finger rod 6 is provided with a locking link extension 7, and a locking link 9 is set at the front end of the locking link extension 7. The two outer fingers 8 are connected to the locking link 9 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com