Method for layout and wiring of pcb with bga chips mounted thereon and pcb made by applying the method

A technology for layout, wiring and chips, applied in the field of electronic circuits, can solve the problems of increasing the development cycle and production cycle of electronic equipment, high distribution density, and time-consuming, shortening development and production time, reducing difficulty, and ensuring functional stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

[0023] A PCB layout and routing method with BGA chips mounted thereon, comprising the following steps:

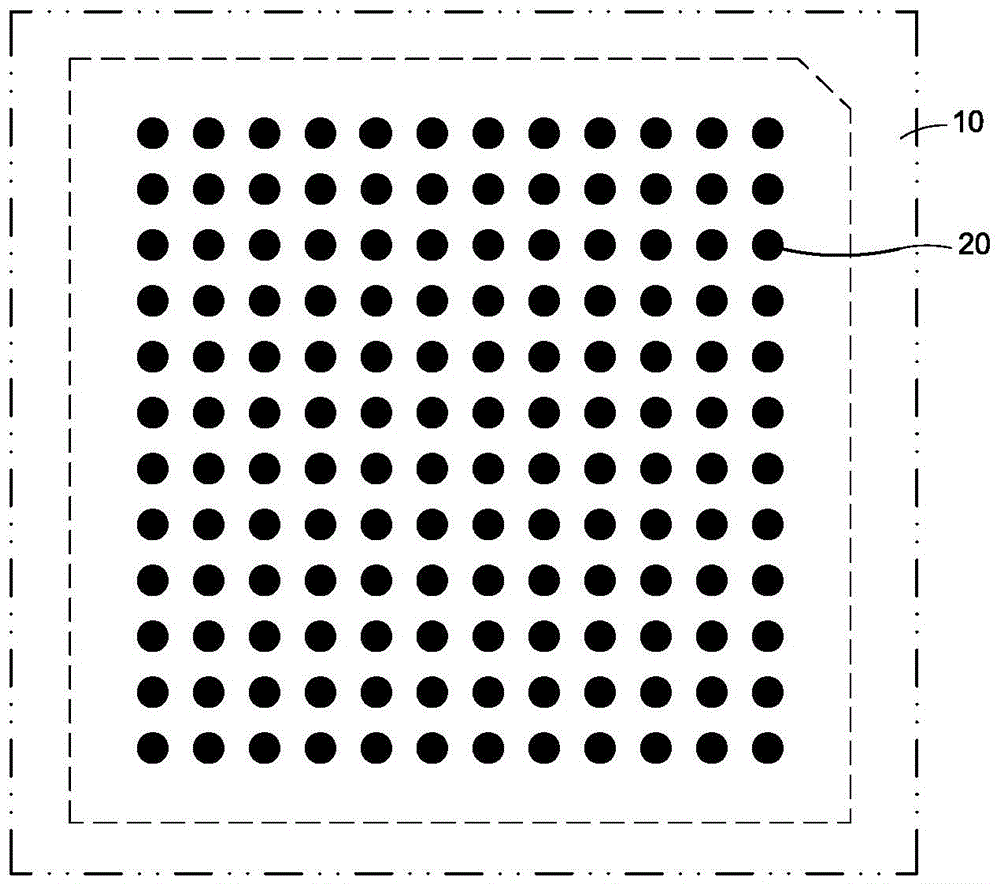

[0024] S1. Provide a PCB to be mounted with a BGA chip, the PCB is provided with solder joints corresponding to the pins of the BGA chip;

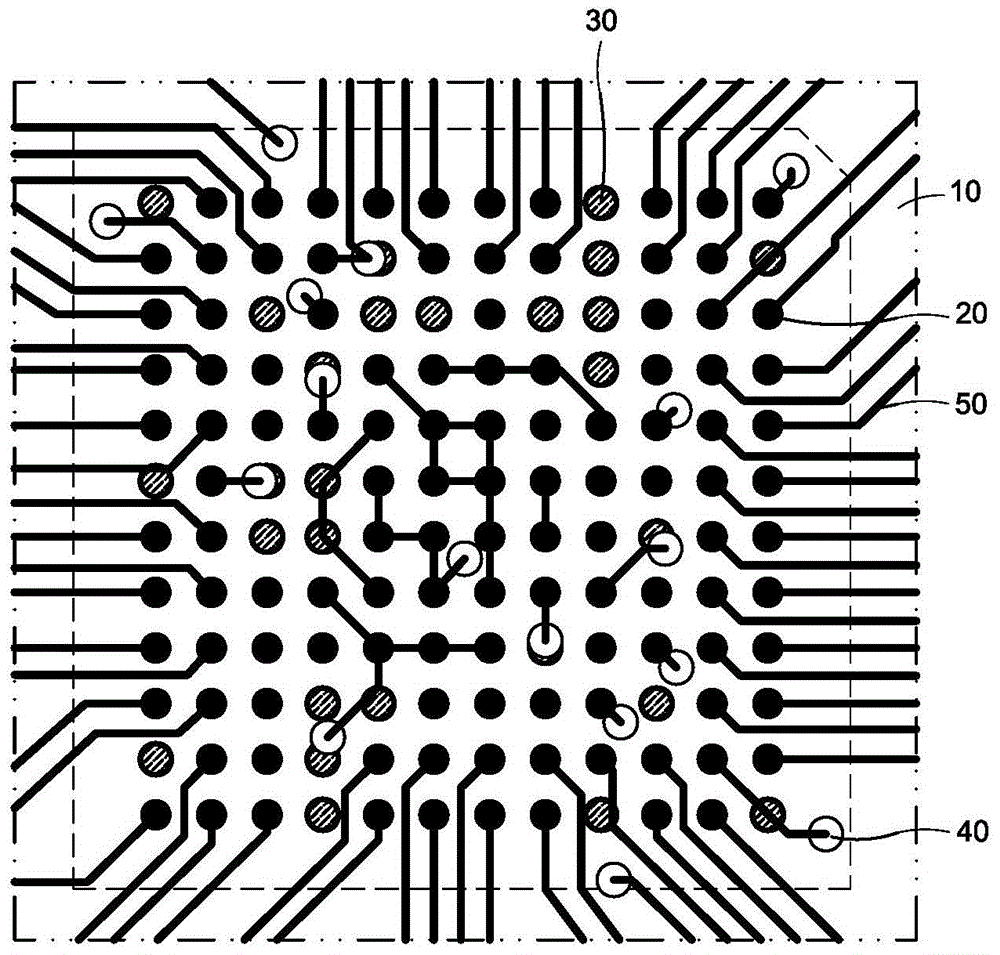

[0025] S2. Confirming that the NC pins of the BGA chip and / or function unused pins correspond to the positions of the solder joints on the PCB;

[0026] S3. Cover the solder joints corresponding to the NC pins of the BGA chip and / or functional unused pins with insulating ink;

[0027] S4. Arranging wires or making metallized through holes in the insulating ink coverage area according to functional requirements.

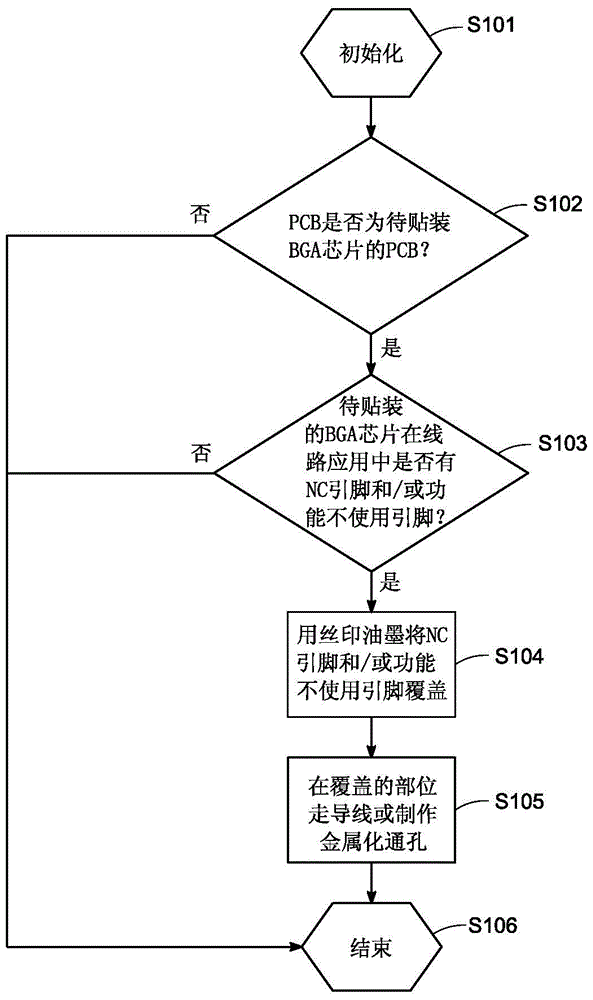

[0028] The specific program flow of the above method is as follows: image 3 Shown:

[0029] The program starts at step S101, performs device initialization at step S101, and enters step S102 after device initial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com