Lifting type station for vacuum environment

A vacuum environment and vacuum technology, applied in the field of transportation, can solve the problems of difficult design technology, complex multidisciplinary comprehensive problems, low cost, etc., achieve great social and economic benefits, fill technical gaps, and low engineering costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

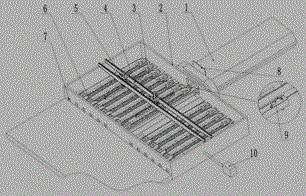

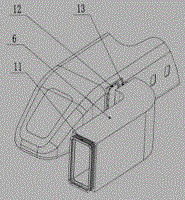

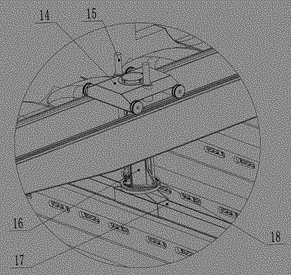

[0018] Embodiments of the present invention are described with reference to the accompanying drawings, below in conjunction with Figure 1 to Figure 3 The present invention will be specifically described. A hoisting station for a vacuum environment, including a vacuum pipeline 1, a vacuum chamber 2, a vacuum train 3, a lifting beam 4, a hoisting mechanism 5, a passenger passage 6, an entrance and exit 7, a valve 8, and a locking mechanism 9 , Vacuum pump group 10, flexible seal 11, body docking door 12, channel docking door 13, running trolley 14, lifting cylinder 15, lifting column 16, lifting beam 17, slewing mechanism 18.

[0019] Vacuum pipeline 1, vacuum chamber 2, and channel docking door 13 form a sealed environment. The end of vacuum pipeline 1 is equipped with valve 8, vacuum chamber 2 is connected with vacuum pump group 10, and lifting mechanism 5 is composed of running trolley 14, lifting cylinder 15, Lifting column 16, hoisting beam 17, slewing mechanism 18 form. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com