Garbage truck compression device

A compression device and garbage truck technology, which is applied in the field of transfer equipment and garbage treatment, can solve the problems of small material compression ratio and low filling efficiency, and achieve the effect of improving compression and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

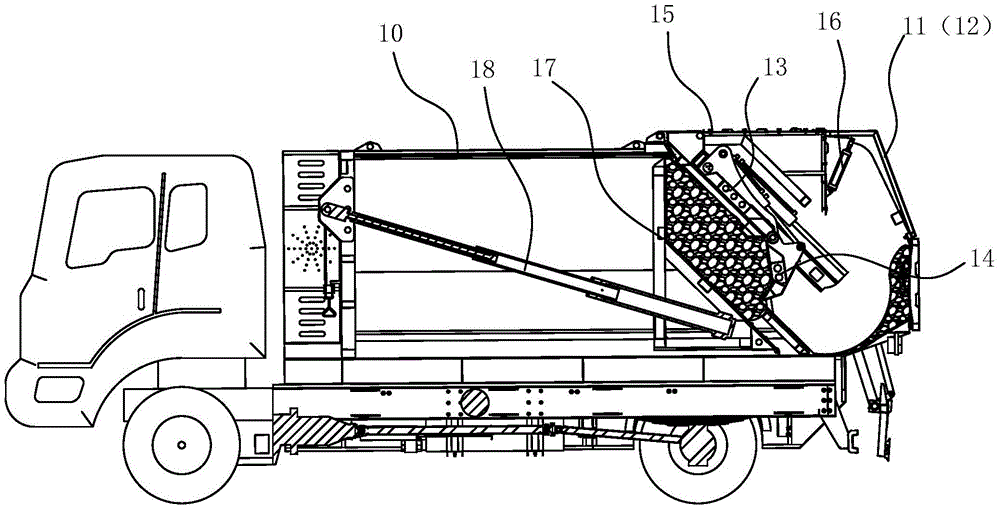

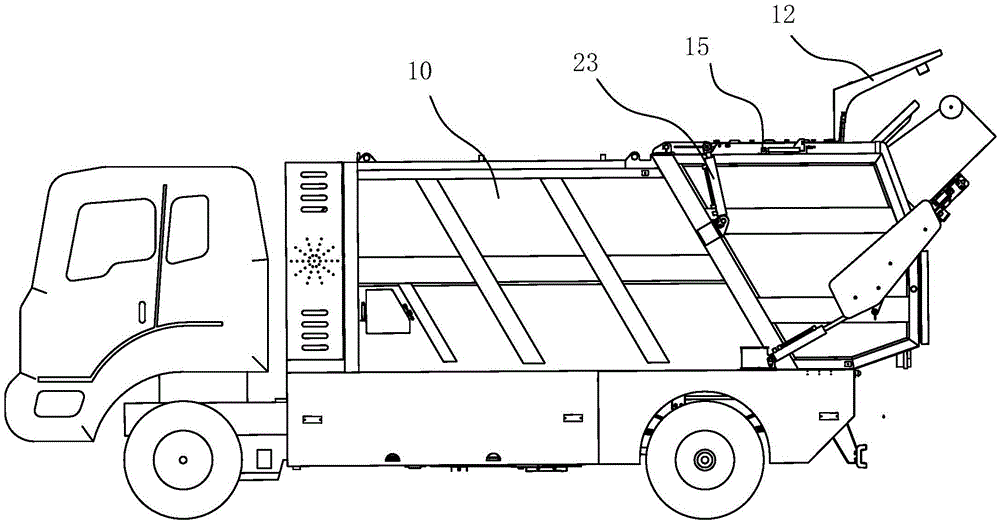

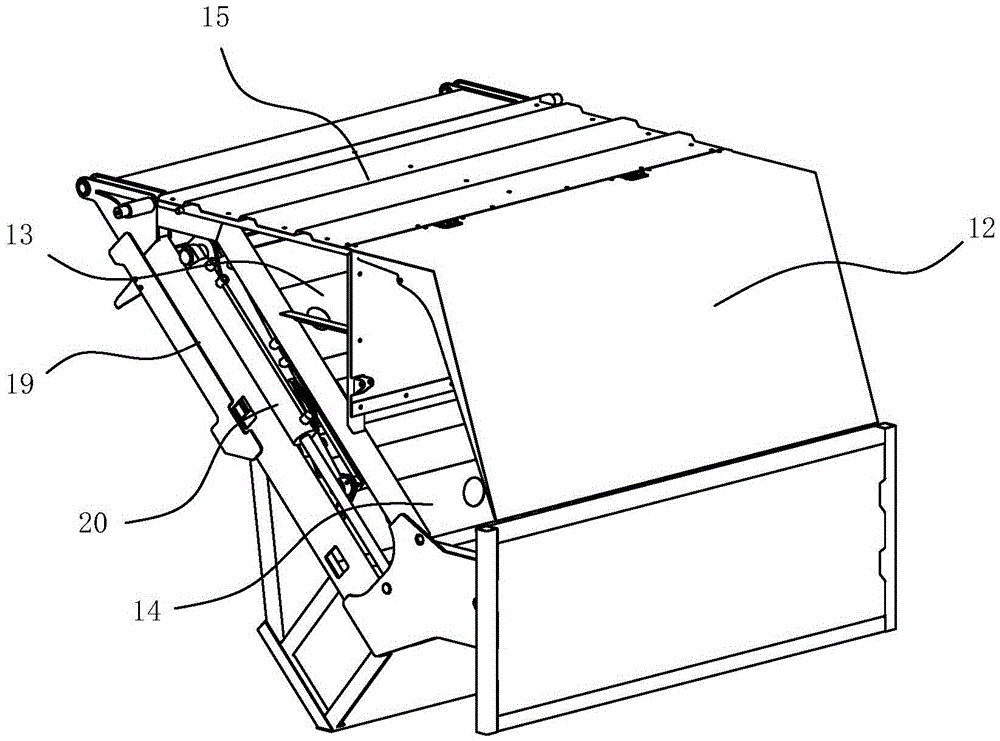

[0012] Such as figure 1 , 4 As shown, a garbage truck compression device, the compression device is located inside the inlet 11 of the garbage truck compartment 10, the compression device includes a turning mechanism and a sliding mechanism, the turning mechanism is arranged on the sliding mechanism, the turning The mechanism, the sliding mechanism, and the unloading push plate 17 in the carriage enclose a squeeze cavity for compressing garbage. The turning mechanism hooks the garbage that enters the feed inlet 11 into the squeezing cavity, and the sliding mechanism drives the turning mechanism to translate. The squeeze cavity space is reduced, and the garbage is compressed.

[0013] The unloading push plate 17 is slidably arranged in the horizontal direction, and the carriage 10 is provided with a first hydraulic cylinder 18 for driving the unloading push plate 17 to slide. During the compression process of the compression device, the first hydraulic cylinder 18 is always maintai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com