Installation method of large bridge crane

A technology of bridge crane and installation method, which is applied to cranes, trolley cranes, transportation and packaging, etc., can solve the problems of high risk factor and high site requirements, so as to reduce the difficulty of hoisting, ensure construction safety, and prevent deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The installation method of the large bridge crane provided in this embodiment, its installation method comprises the following steps:

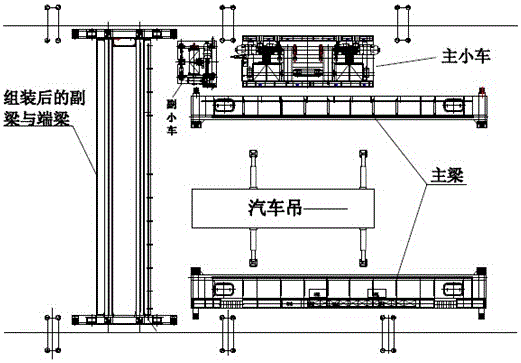

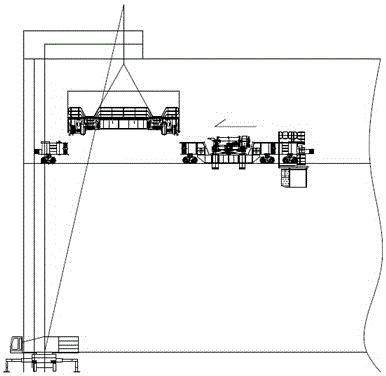

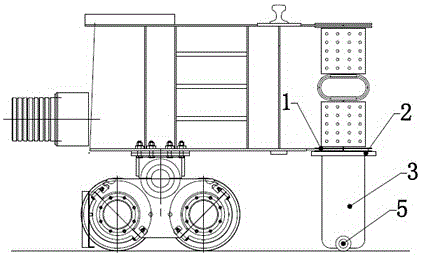

[0030] A. Organize the hoisting site to ensure the strength and flatness of the site; B. Use drawing software to draw the layout of the crane components through multiple computer simulations of hoisting and on-site surveys (such as figure 1 shown) and reserve the location of the truck crane, where the truck crane is located below the crane that needs to be installed; C. According to the weight of the main girder, sub-beam, end beam, main trolley in the crane and the hoisting height required on site, choose a Car cranes for hoisting weight and height, among them, because the main trolley is too heavy as a whole, before hoisting, its drum, motor, reducer and other components need to be removed; D. Check whether each hoisting equipment is qualified, and use the car crane to separately The main beam, auxiliary beam, end beam, auxiliary trol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com