A starch raw material crushing and sedimentation device

A precipitation device, starch raw material technology, applied in sustainable manufacturing/processing, grain processing, chemical industry, etc., can solve the problems of water consumption, sewage generation, low efficiency, etc., to reduce wear, low cost, and prevent missing cutting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the present invention, preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limit the claims of the present invention.

[0024] The solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

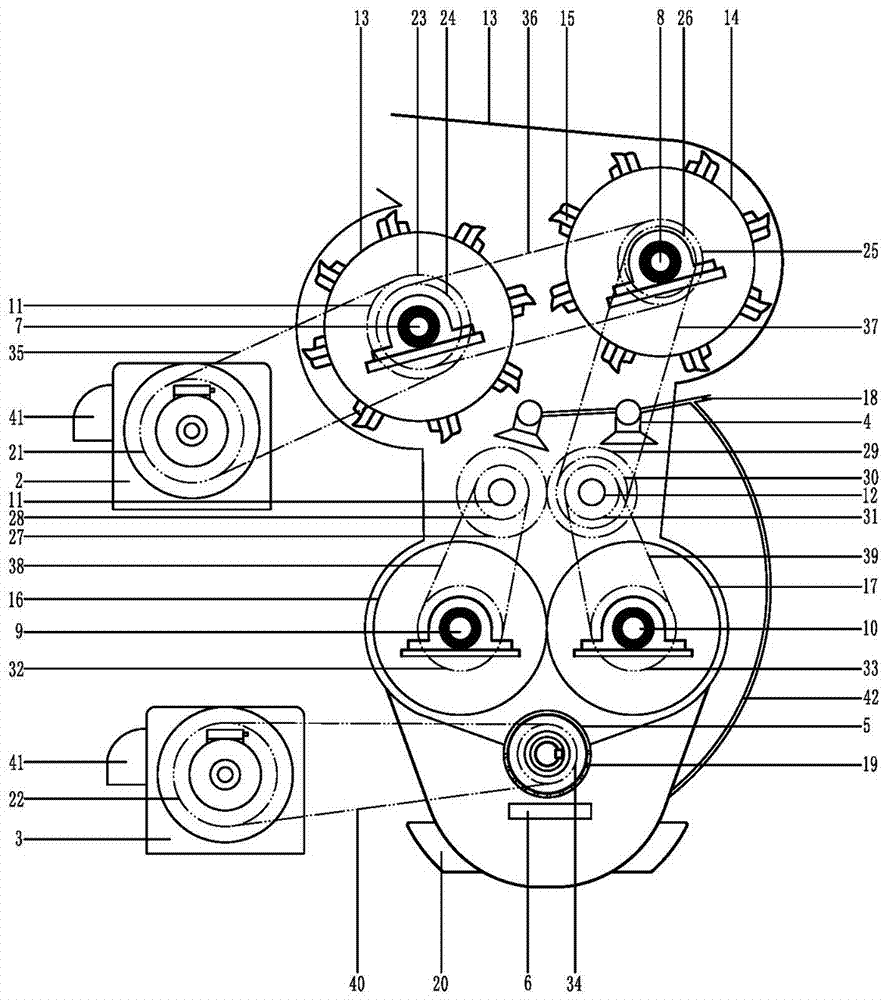

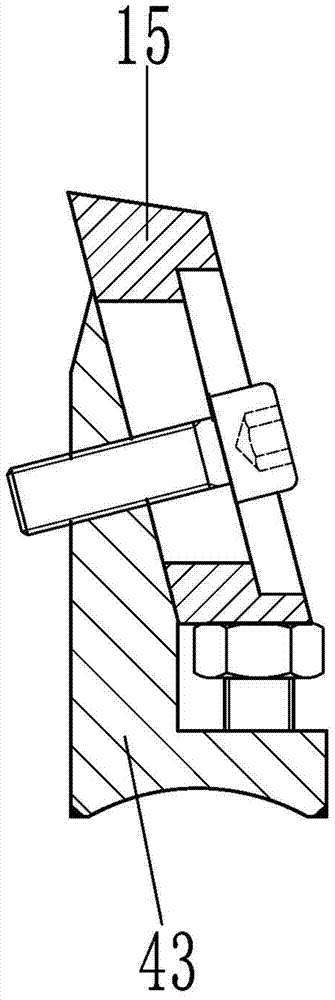

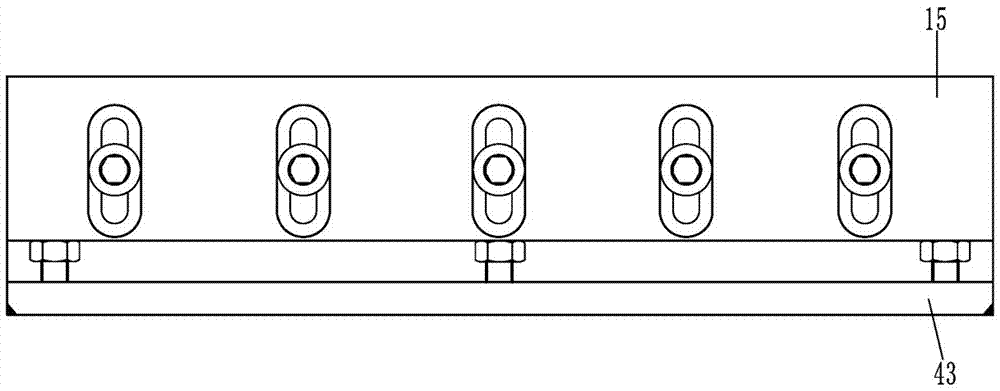

[0025] A starch raw material crushing and sedimentation device according to an embodiment of the present invention includes a cabinet 1, a first cycloidal motor 2, and a second cycloidal motor 3, and the cabinet 1 is provided with a water spout 4, a screw extrusion mechanism 5 and a water wave turbine 6 , the chassis 1 is divided into an upper chassis and a lower chassis, and the top of the chassis 1 is provided with a feed port.

[0026] The cabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com