Rubber shock absorber

A rubber shock absorber and rubber technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of not considering resonance effects, casualties, failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

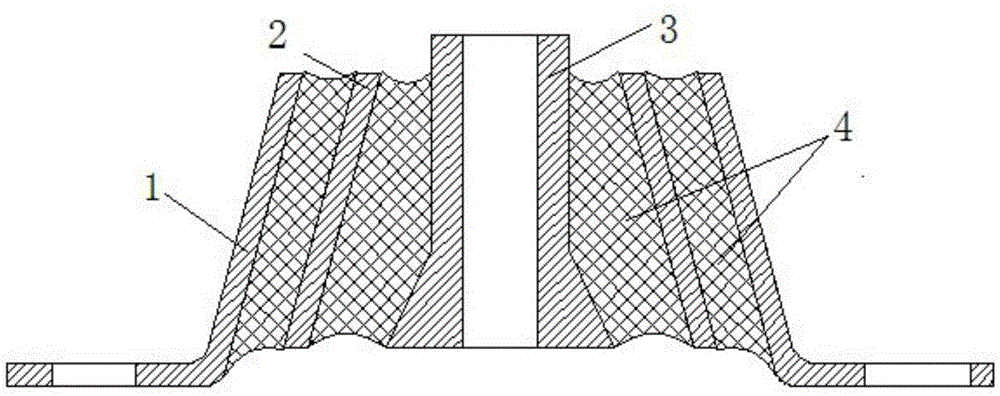

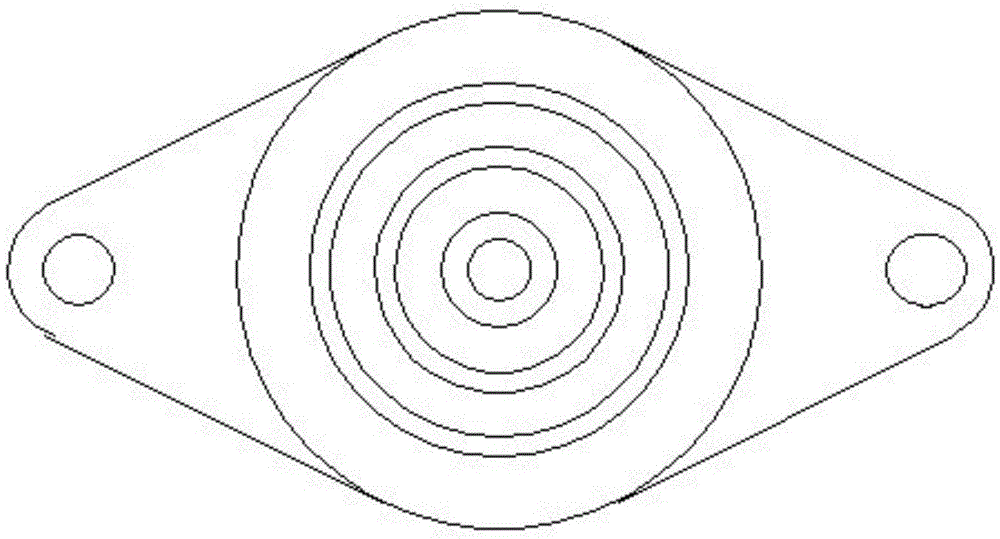

[0010] Attached below Figure 1-2 The present invention is further described:

[0011] The present invention is mainly composed of a metal mounting seat 1, a reinforcing ring 2, a positioning shaft 3 and a rubber support body 4. The rubber support body 4 is vulcanized rubber, and is respectively arranged on the positioning shaft 3 and the reinforcing ring 2, the reinforcing ring 2 and the mounting seat 1. Between; the three parts of the metal mounting seat 1, the reinforcing ring 2, and the positioning shaft 3 are all metal parts and the contact surface with the rubber is vulcanized. The three parts are combined into a whole by rubber. The mounting seat 1, the reinforcing ring 2 and the positioning shaft 3 are not in contact with each other, and the elastic connection between the positioning shaft 3 and the metal mounting seat 1 can be realized, and the vibration and noise are reduced; the center of the positioning shaft 3 is provided with a light hole or a threaded hole. When...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com