Axle sleeve shock absorber and vehicle

A shock absorber and bushing technology, applied in the direction of shock absorber, shock absorber-spring combination, shock absorber, etc., can solve the design requirements that are unfavorable to the handling stability and comfort of the whole vehicle, and the controllability of the whole vehicle. Insufficient comfort, no damping and vibration reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

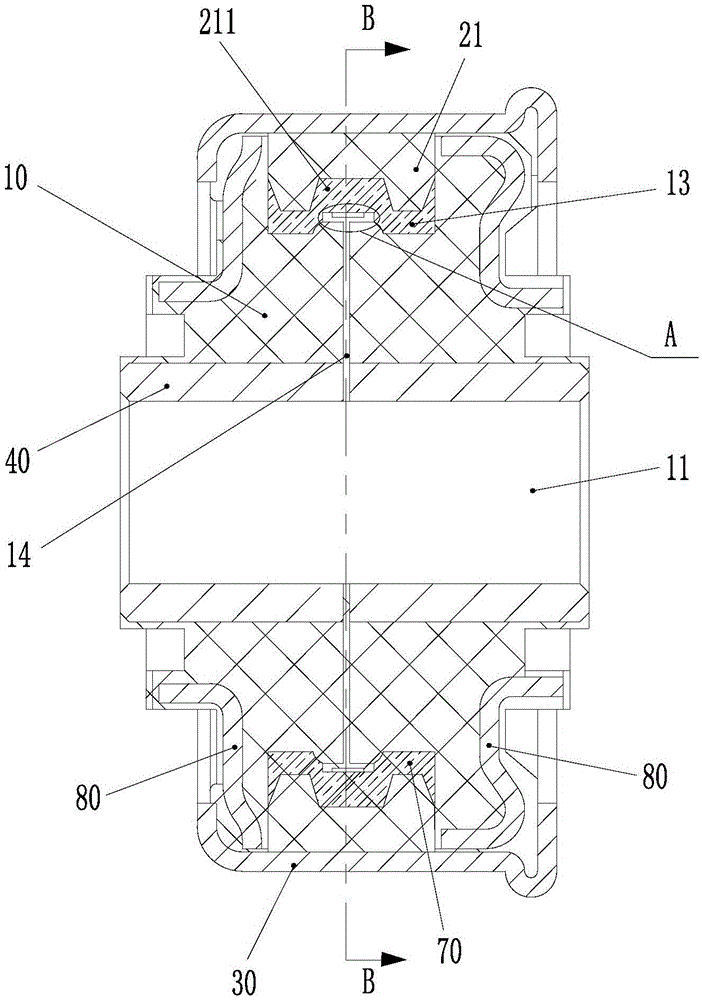

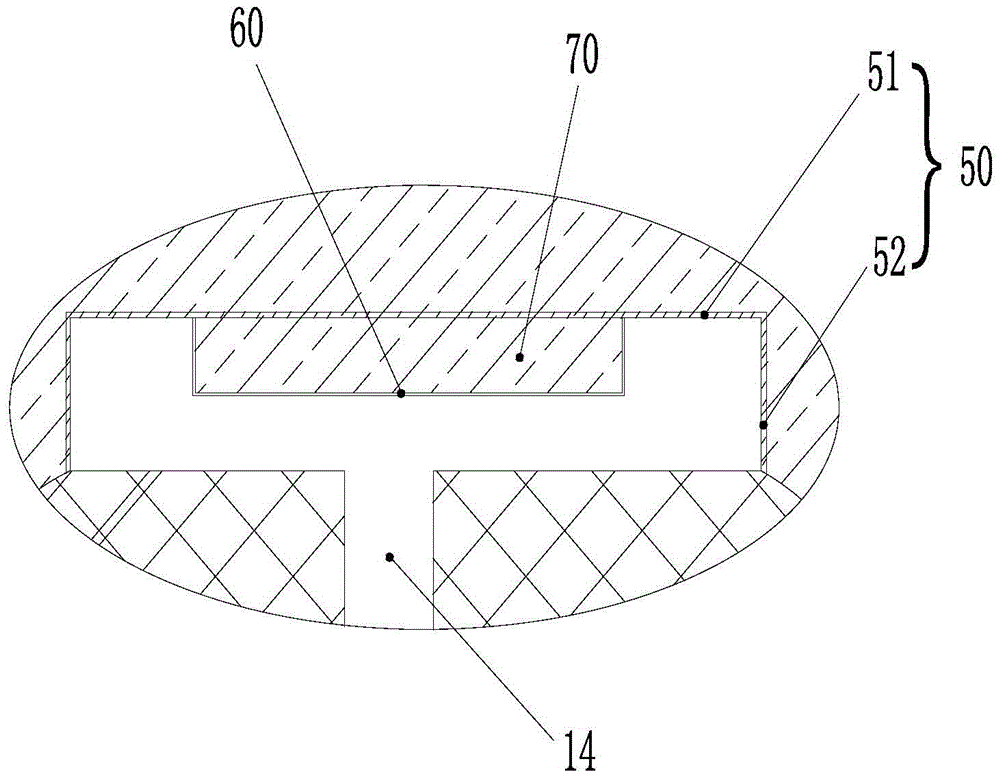

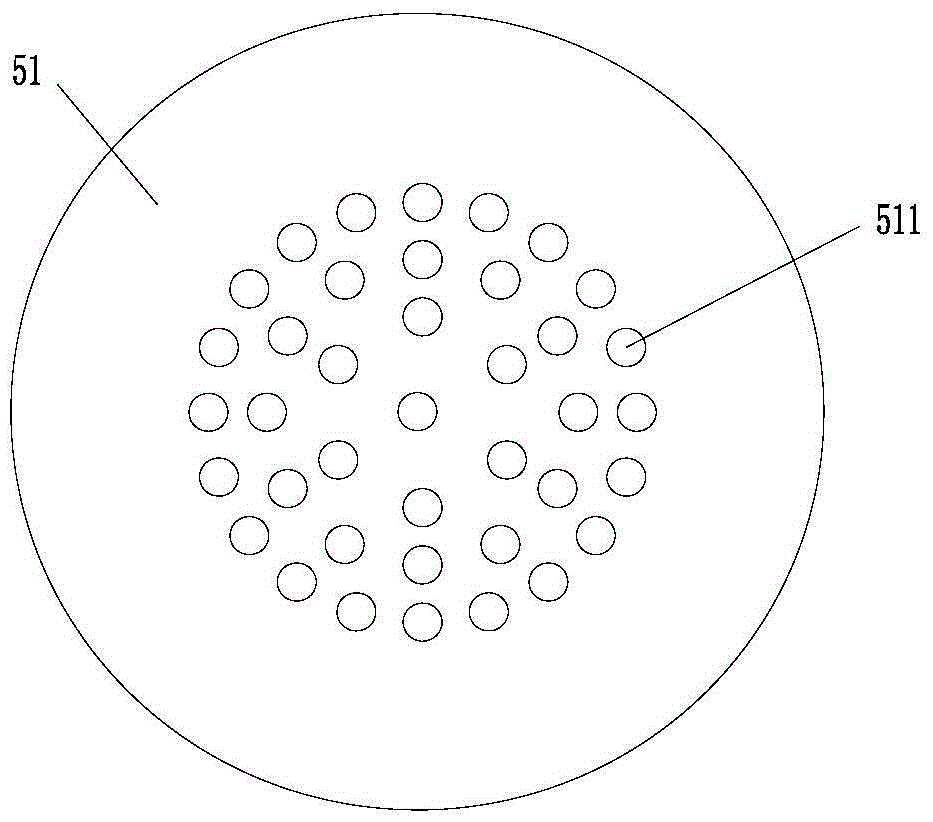

[0031] Such as Figure 1 to Figure 4 As shown, the present invention provides a bushing shock absorber, including a rubber bushing body 10, a sealing rubber ring 20 and a metal shell 30, the rubber bushing body 10 has a shaft hole 11 for the external connecting shaft to pass through, and the rubber bushing The outer peripheral surface of the body 10 is provided with an annular groove 12 extending along its circumference, the sealing rubber ring 20 is embedded in the annular groove 12, and the inner peripheral surface of the sealing rubber ring 20 is separated from the bottom surface of the annular groove 12 to form an annular The annular channel is filled with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com