Main shaft mounting structure of rear-drive transmission

A technology for installation structure and transmission, which is applied in the directions of transmission parts, belts/chains/gears, mechanical equipment, etc., to achieve the effect of convenient and easy assembly, low cost, and reducing the risk of thread tolerance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

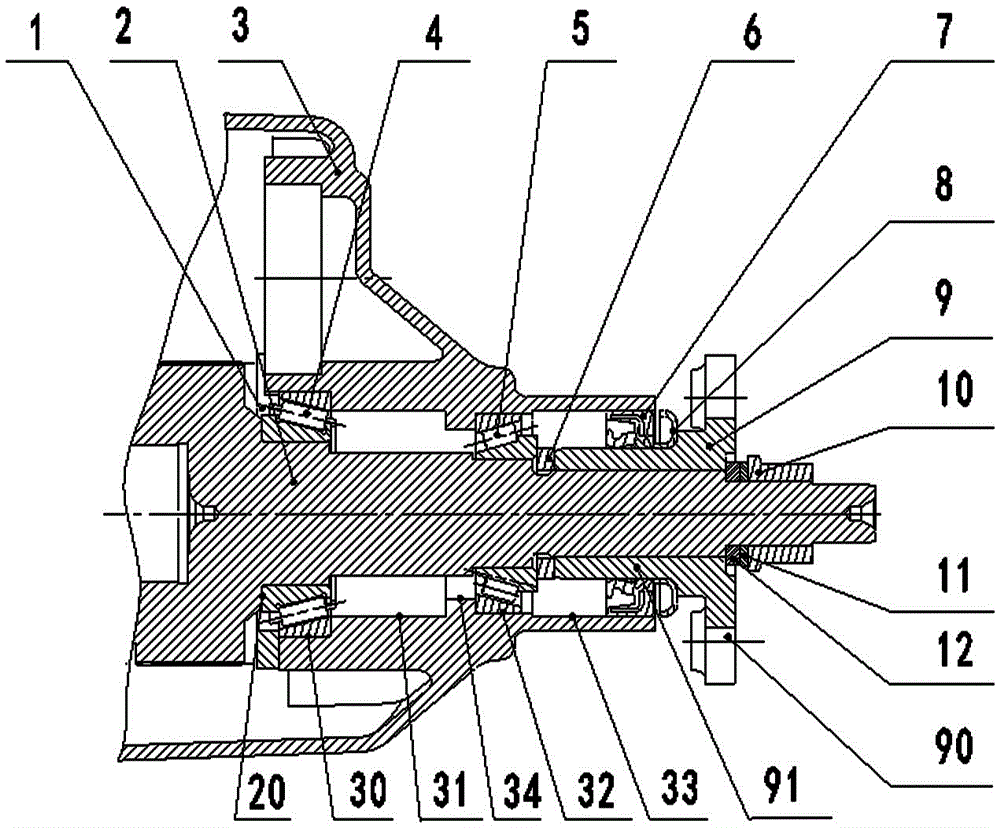

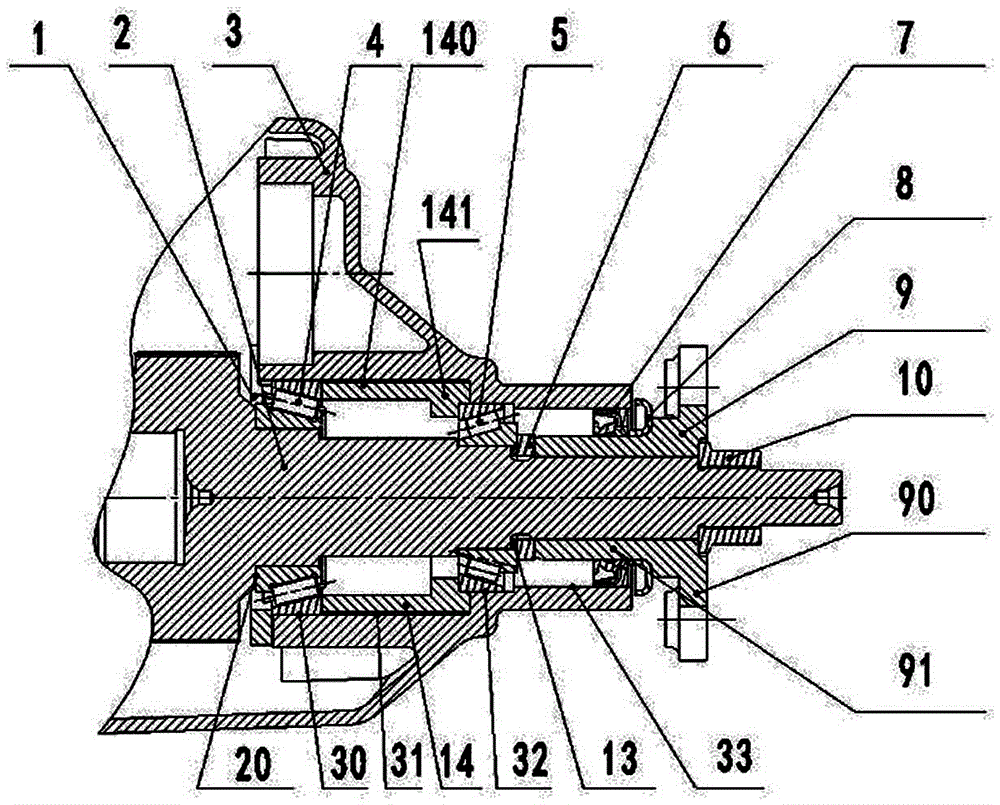

[0017] see figure 2 The main shaft installation structure of the rear drive transmission of the present invention includes a front bearing pressure plate 1, a main shaft 2, a front bearing assembly hole 30, a transition assembly hole 31, which are arranged from front to back and coaxial, and communicate with each other. Spindle case body 3 with rear bearing assembly hole 32 and flange assembly hole 33, front bearing 4, rear bearing 5, retaining ring 6, oil seal 7, dust cover 8, flange 9 and lock nut 10 all of which are taper bearings The front end of the main shaft 2 is provided with a front bearing stopper 20 protruding radially outward from the shaft body of the main shaft 2, and the flange 9 includes a disc body 90 and is integrated with the disc body 90 and formed by the The sleeve body 91 extending forward on one side of the di...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap