Combustor capable of injecting fluid at combustor outlet

A technology of burners and ejectors, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as unstable combustion and easy oscillation, and achieve the goals of enhancing combustion stability, reducing flame height, and improving combustion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

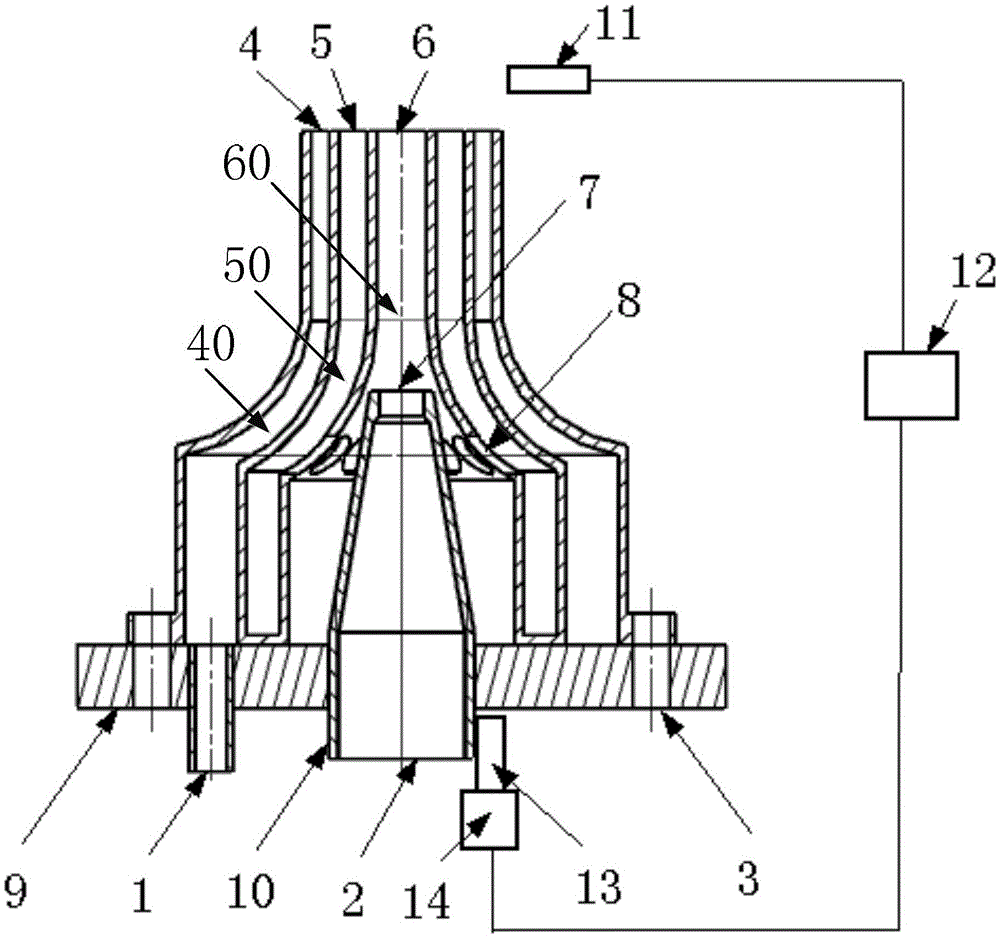

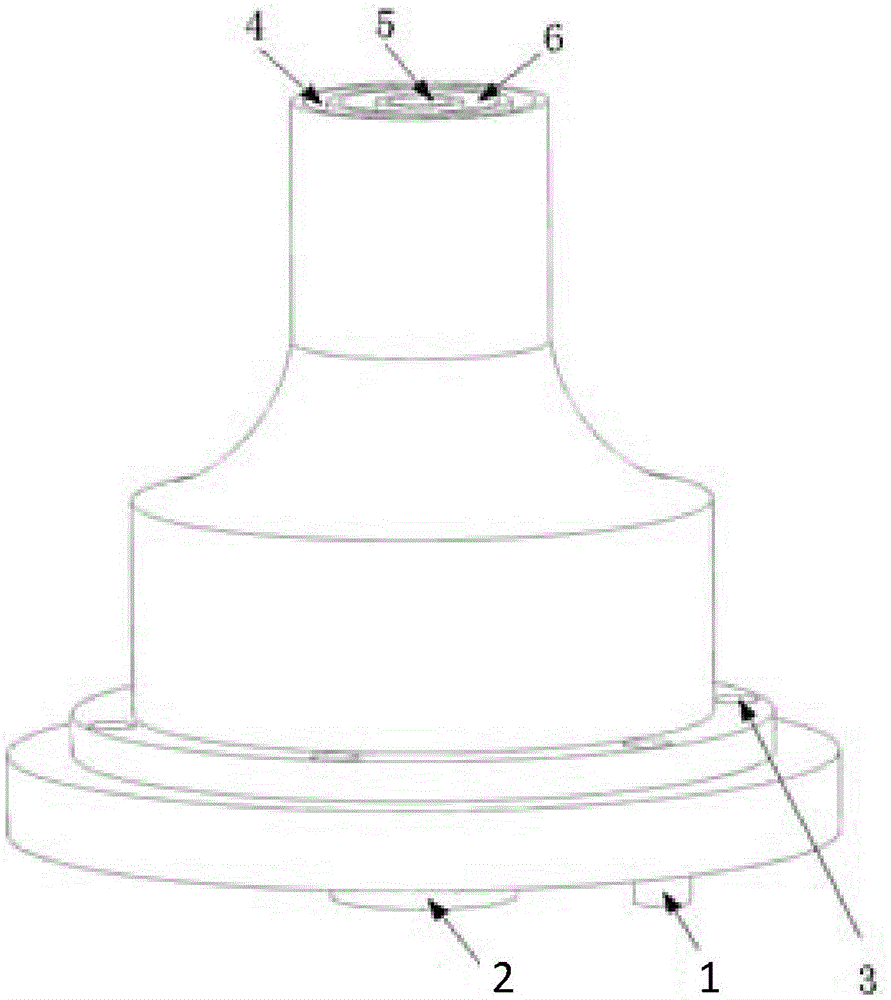

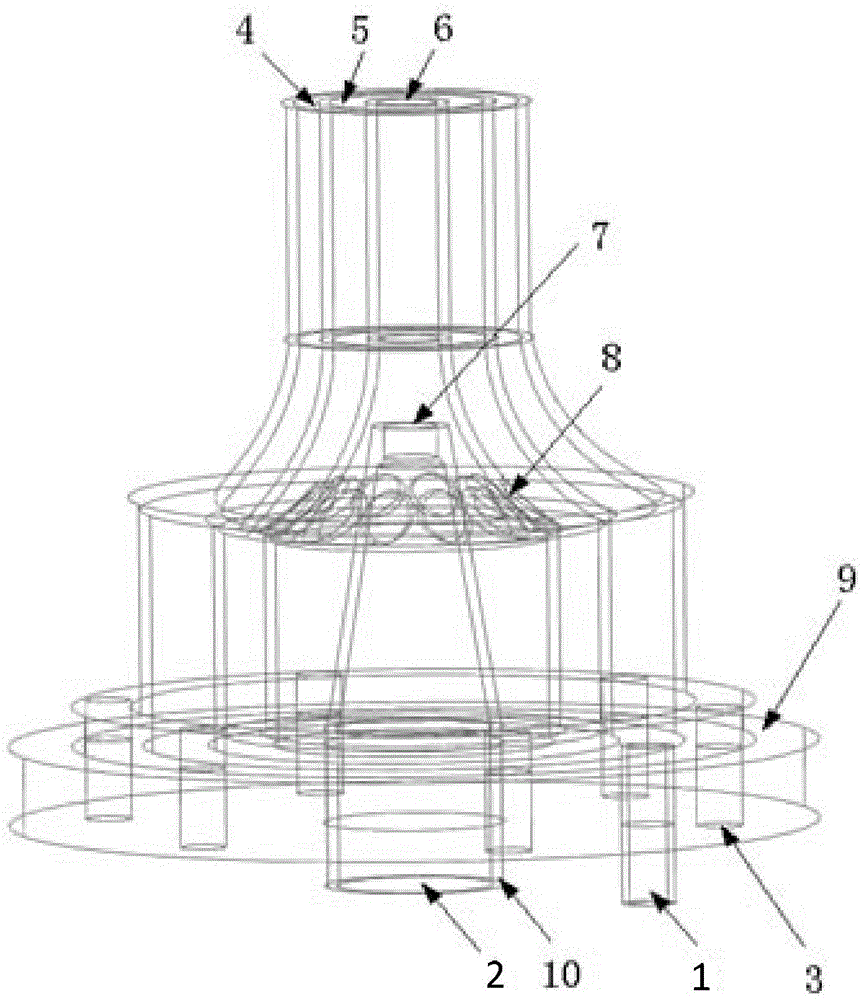

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. In the drawings of the present invention, the same reference numerals denote the same components.

[0038] In the burner that can inject fluid at the outlet of the burner according to the present invention, the fluid near the outlet of the burner is injected by the fluid participating in the combustion reaction. Under the control of the single-chip microcomputer, the amount of injected gas is automatically controlled according to the combustion state, which can be preheated. Combustion of reactants, promotion of fluid mixing in the combustion zone, improvement of combustion state, enhancement of combustion stability, shortening of flame length, widening the stable operating range of the burner, improving combustion efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com