Finned tube

A finned tube and water tube technology, applied in the field of heat dissipation accessories, can solve the problems of short life, general heat dissipation effect, poor corrosion resistance, etc., and achieve the effects of low manufacturing cost, simple structure, and improved heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

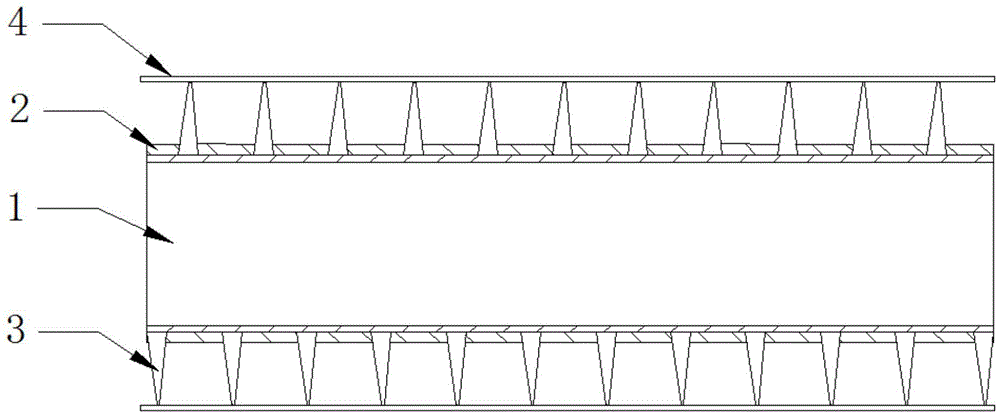

[0012] A finned tube, comprising a base pipe 1, an anti-corrosion layer 2, a heat sink 3, and a water pipe 4, the base pipe 1 is provided with an anti-corrosion layer 2, the outside of the anti-corrosion layer 2 is provided with uniformly wound heat sinks 3, and the top of the heat sink 3 is provided with There are water pipes4.

[0013] Further, the material of the anti-corrosion layer 2 is a corrosion-resistant cement coating.

[0014] Further, there are 4 water pipes 4 in total.

[0015] The embodiments of the present invention have been described in detail above, but the content described is only a preferred embodiment of the present invention and cannot be considered as limiting the implementation scope of the present invention. All equal changes and improvements made according to the creative scope of the present invention should still belong to the scope covered by this patent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com