A demoulding method for a skeleton-free optical fiber ring demoulding skeleton

A fiber optic ring and skeletonless technology, which is applied in the field of skeletonless fiber optic ring stripping skeleton and stripping, can solve the problems of poor consistency of fiber optic rings, no relatively perfect methods, adverse effects on performance, etc., and achieve good consistency and smooth appearance , The effect of small additional stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

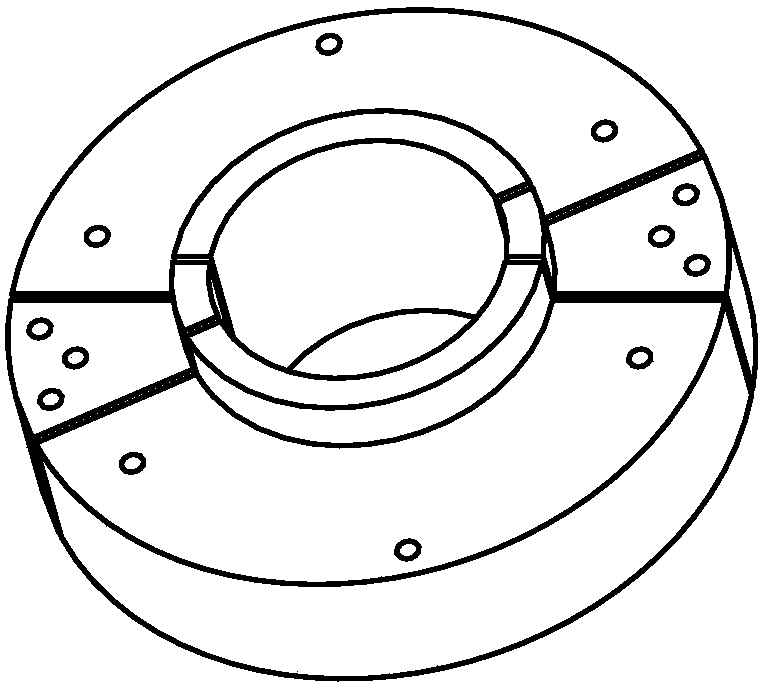

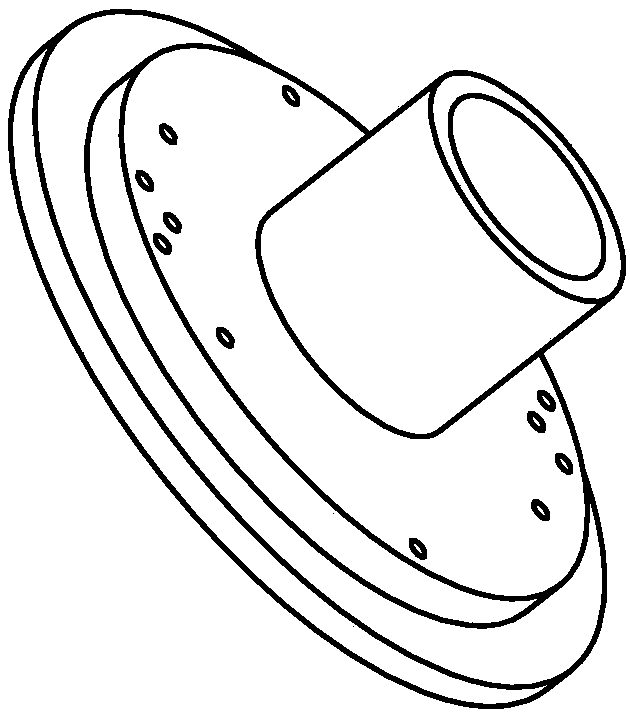

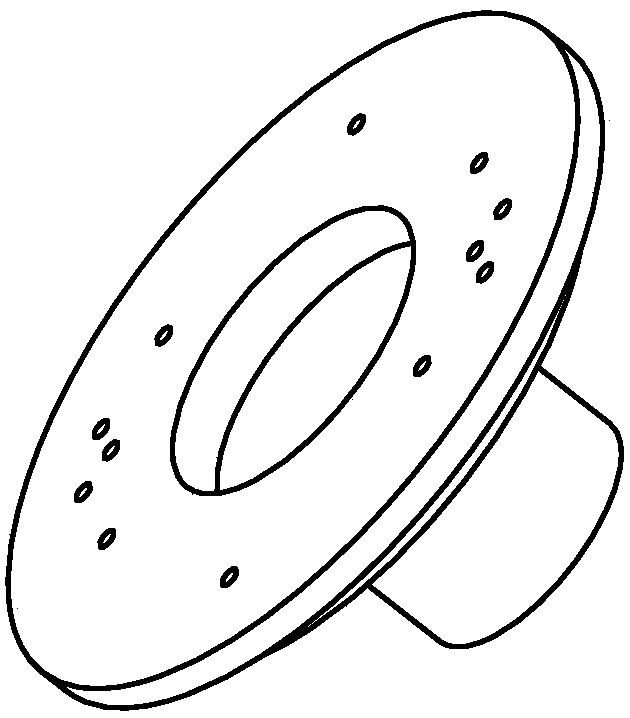

[0050] join figure 1 ~Figure 4, a skeletonless optical fiber ring release skeleton, including the following parts:

[0051] (1) The demoulding skeleton is a three-body structure with left, middle and right sides, the retaining ring 1 is on the left, the ring body 3 is in the middle, and the transition body 4 is on the right. Between the retaining ring 1 and the surrounding body 3 , between the surrounding body 3 and the transition body 4 are all connected and fastened by hexagon socket head cap screws 5 .

[0052] (2) The ring body 3 in the middle is cut into four fan pages by wire cutting, in an "X" shape, the angle between the small fan pages is 20-35 degrees, the angle between the large fan pages is 145-160 degrees, and the wire cutting width is 0.2~0.4mm. There are three screw holes for triangular positioning on each leaf. Before wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com