Optical Dynamic Balancing Machine

A dynamic balancing machine and optical technology, which is used in static/dynamic balance testing, machine/structural component testing, measuring devices, etc. Convenient and fast, improve measurement accuracy, and overcome the effect of underground detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

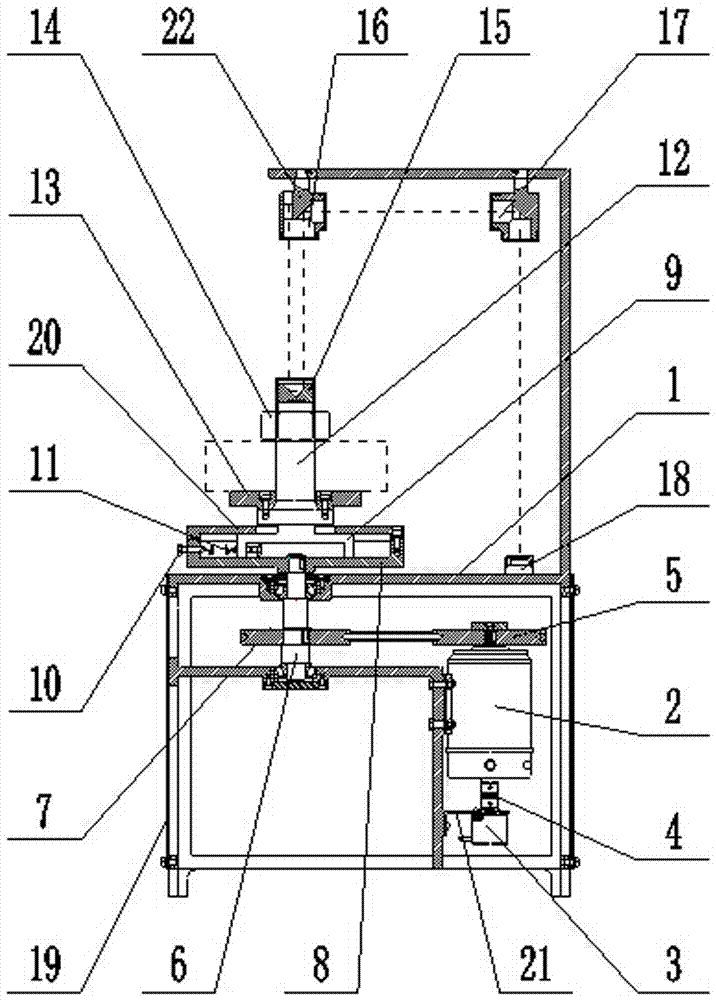

[0011] The optical dynamic balancing machine includes a frame 1. The side wall of the frame 1 is provided with a vertically arranged DC motor 2. A photoelectric rotary encoder 3 connected to the frame 1 is provided below the DC motor 2. The photoelectric rotary encoder 3 An elastic coupling 4 connected with the DC motor 2 is arranged, a driving wheel 5 is arranged above the DC motor 2, a rotating shaft 6 is arranged on the frame 1, and a driven wheel 7 is arranged on the rotating shaft 6, The driven wheel 7 and the driving wheel 5 are driven by a belt, and the upper end of the rotating shaft 6 is connected with a hollow flange 8 located above the frame 1, and the hollow flange 8 is sleeved with an inverted hollow flange I9. I9 and the hollow flange 8 are all screwed with some pairs of holed bolts 10 evenly arranged with both centers as the center of a circle, and each pair of holed bolts 10 is provided with an extension spring 11 connected to both, The upper end of the hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com