Flexible member assembling dimensional deviation control method based on multi-station assembly jig compensation

A technology for assembling fixtures and assembly dimensions, which is applied in the direction of program control, computer control, general control system, etc., can solve problems such as poor adaptive control, and achieve the effect of ensuring the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

[0033] Such as Figure 1-10 shown.

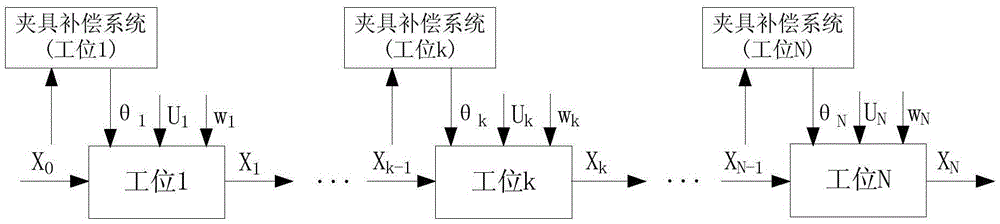

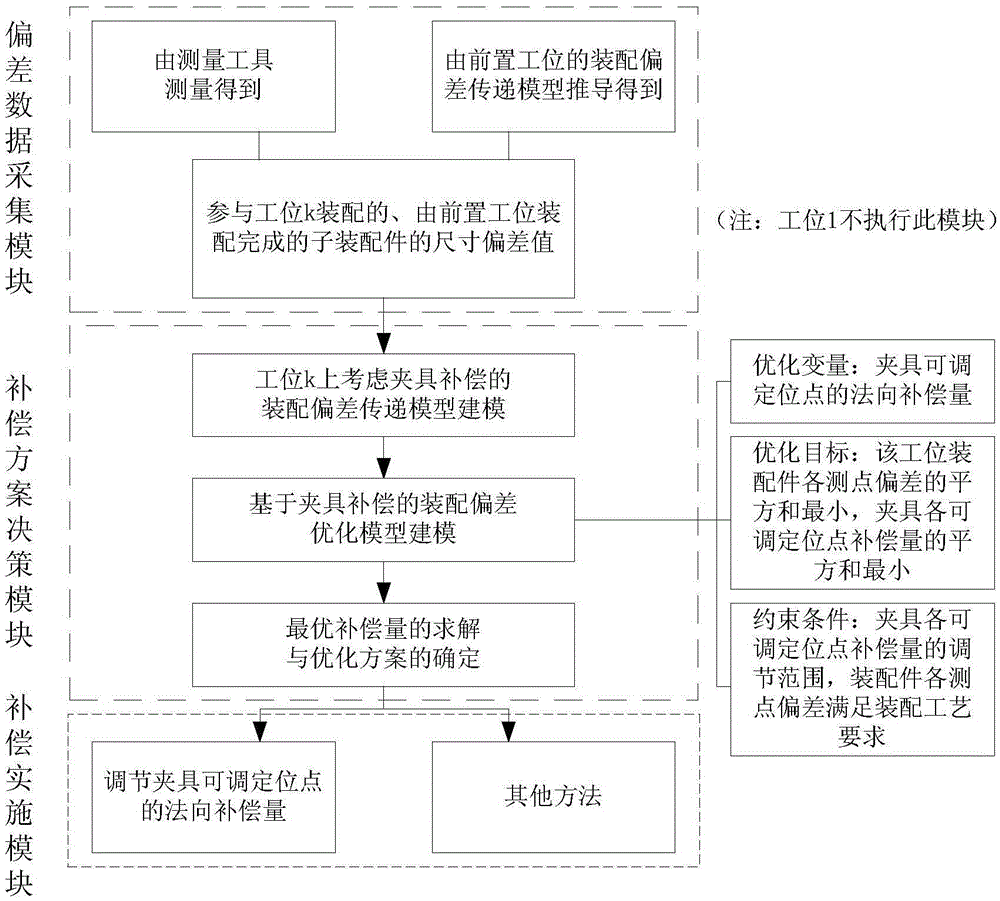

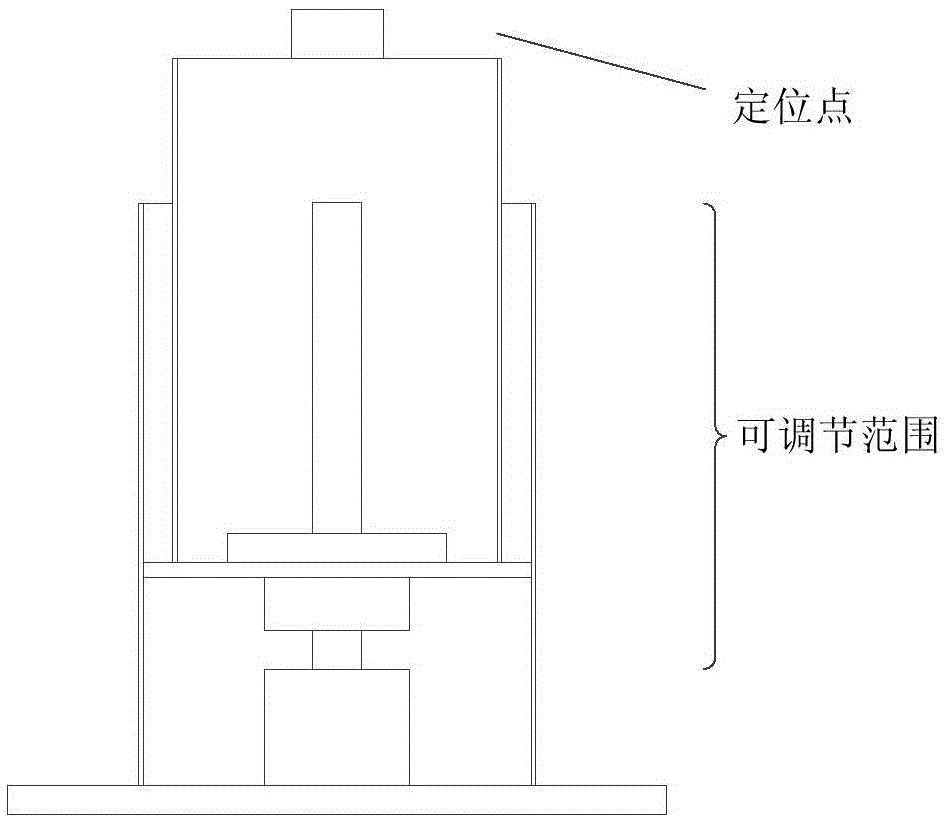

[0034]A dimensional deviation control method for flexible parts assembly based on multi-station assembly fixture compensation, which predicts and compensates assembly deviations station by station during the multi-station assembly process of flexible parts, and makes the position of the fixture positioning point participating in the fixture compensation within a certain position. It can be adjusted normally within the range. At the same time, based on the state space method in control theory, a fixture compensation system is added to the positioning or repositioning link of the multi-station assembly of flexible parts to collect deviation data, optimize compensation schemes and implement compensation, so as to reduce the number of stations to be assembled. assembly deviation on the The details are as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com