Hot-spot-preventing photovoltaic panel

A technology for photovoltaic panels and heat protection, applied in the direction of photovoltaic power generation, photovoltaic modules, photovoltaic module support structures, etc., can solve the problems of shortening the life of photovoltaic panels, significant impact, waste of resources, etc., to eliminate hot spot effects, avoid The effect of frequent cleaning and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

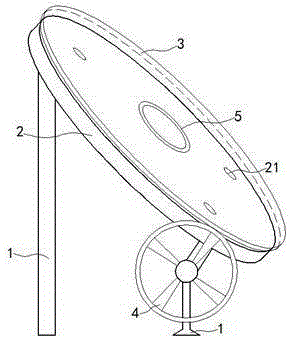

[0013] exist figure 1 In the shown embodiment, the anti-hot spot photovoltaic panel includes a bracket 1 and a power generation board 2, and the bracket 1 is installed on the lower side of the power generation board 2; the light-receiving surface of the power generation board 2 is inclined upward at an angle of 45 degrees; A rotating shaft is fixedly installed in the center of the power generation board 2, and a dust-proof plate 3 is sleeved on the rotating shaft. The dust-proof plate 3 is made of a high light-transmitting material, and its shape is a round cake. The upper surface of the dust-proof board 3 is inlaid with wire mesh, and the size of the wire mesh is relatively small, not shown in the figure; on the round edge of the dust-proof board 3, there are tooth grooves; between the dust-proof board 3 and Sealing oil is coated between the power generation panels 2; the anti-hot spot photovoltaic panel also includes a fan 4, and teeth meshing with the alveolar are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com