Secondary-etching double-sided circuit board structure and processing technique thereof

A double-sided circuit board, secondary etching technology, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of uncontrolled product quality, long cycle cycle, large cost investment, etc., to simplify the production process The effect of operation difficulty, reduction of PCB production cost, and reduction of human resources investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

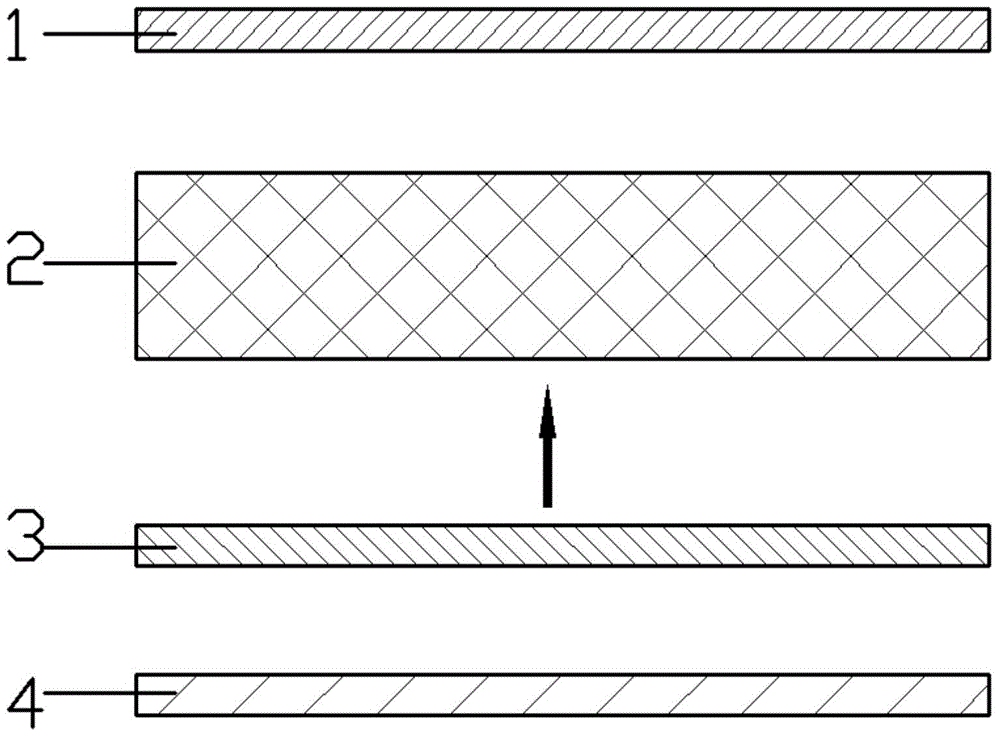

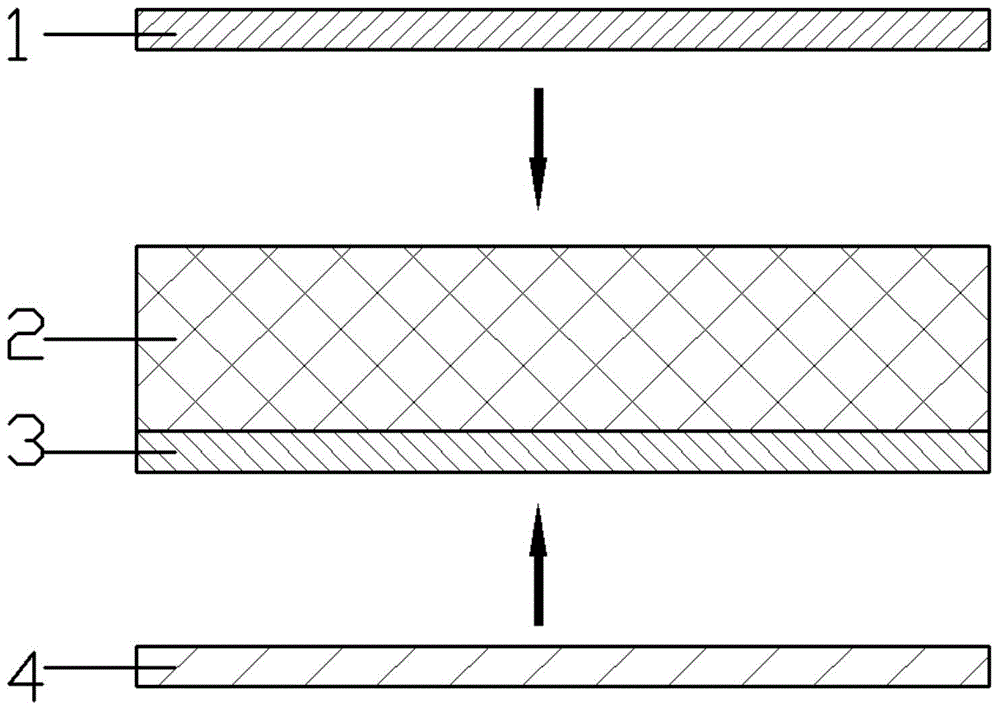

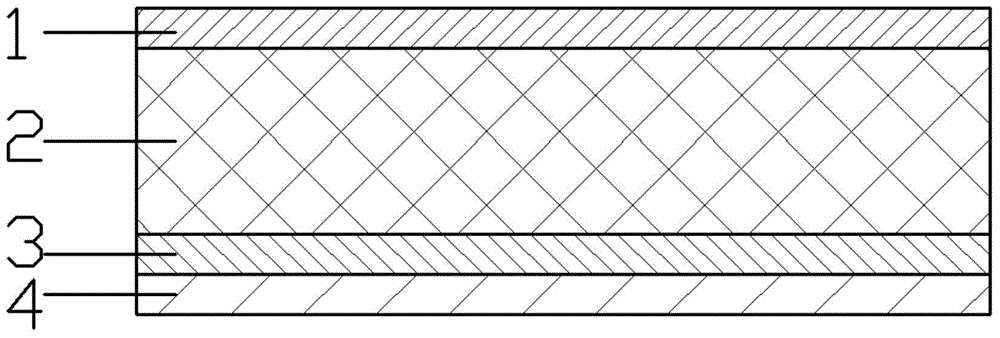

[0028] Such as image 3 As shown, a secondary etching double-sided circuit board structure includes: GTL line layer 1, insulating PP layer 2 and GBL step surface line layer, characterized in that: the GBL step surface line layer is composed of GBL inner line layer 3 and The GBL outer line layer 4 is formed, the insulating PP layer 2 is located between the GTL line layer 1 and the GBL inner line layer 3, the GBL outer line layer 4 is located on the other side of the GBL inner line layer 3, and the GBL outer line layer 4 is similar to the appearance shape of the GBL inner circuit layer 3, but the size B1 of the GBL inner circuit layer 3 is larger than the size B2 of the GBL outer circuit layer 4, and the size relationship is preferably: B1=B2+0.05mm. The production process of etching double-sided circuit boards includes the sub-process of the first circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com