Method for producing connection element, and connection element

A technology for manufacturing connections and connectors, applied in the direction of towers, building types, buildings, etc., can solve the problems of complex manufacturing, dangerous shrinkage, uneven materials, etc., and achieve the effect of reducing the number of parts, improving fatigue strength, and reducing notch effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

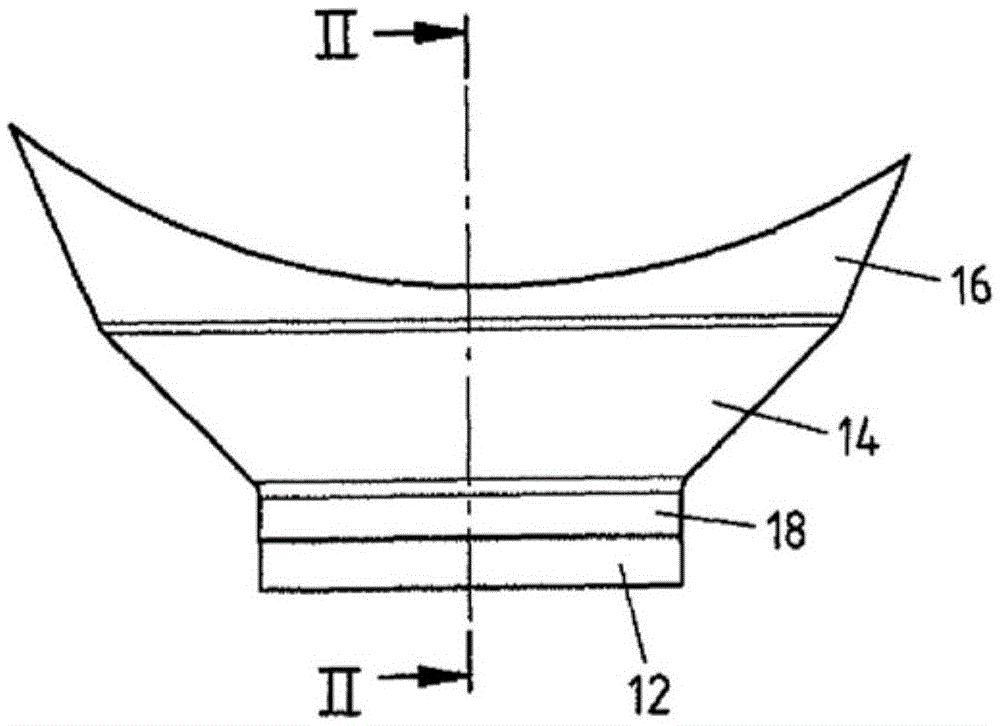

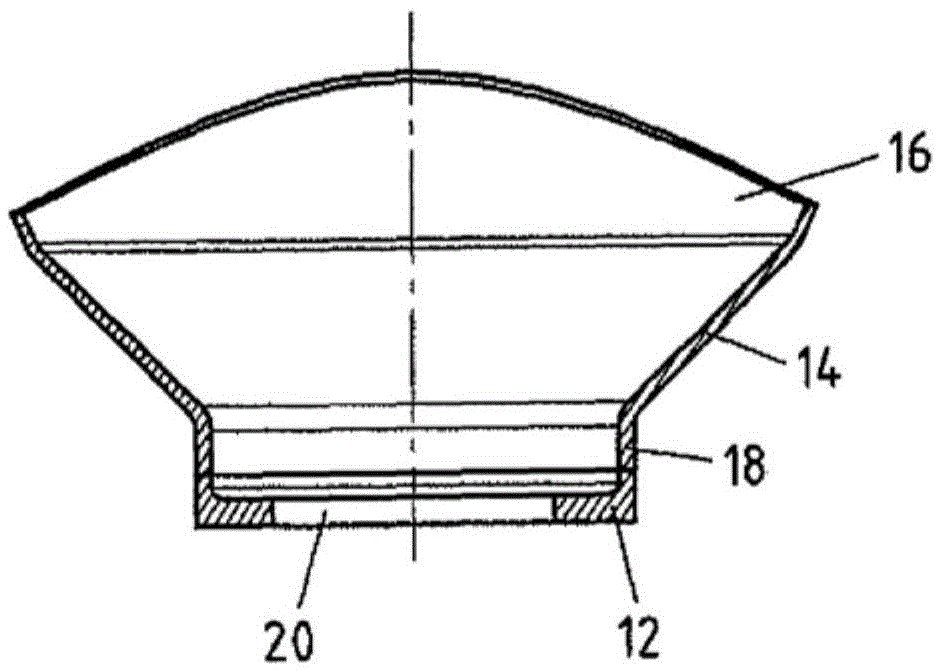

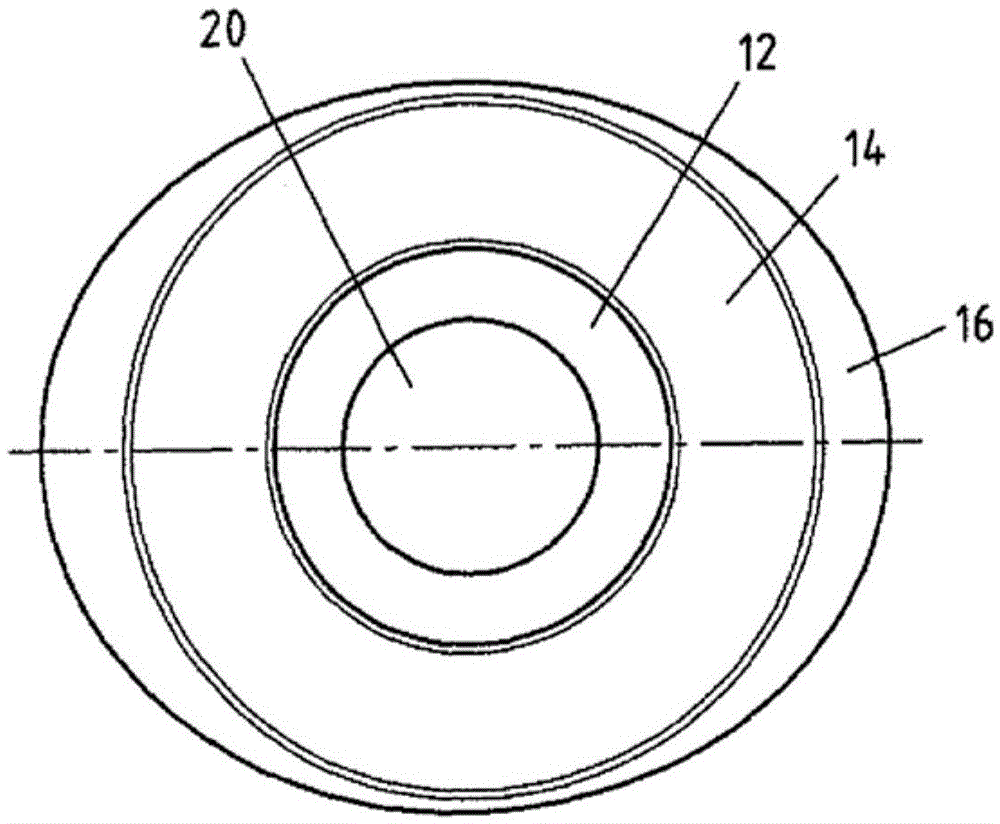

[0028] attached Figures 1 to 4 A first embodiment of a connection or fitting 10 according to the invention is shown in .

[0029] The connection or connecting element 10 shown is referred to below only as a connecting element, which is especially suitable for the steel structure of a tower, preferably for a wind power plant, and which is produced in particular by the method according to the invention.

[0030] The connecting piece 10 has a flange 12 and a housing 14, wherein the housing 14 is connected in one piece to the flange 12 and wherein the end of the housing 14 opposite the flange 12 is adapted to a steel structure, in particular having a round or polygonal shape. The profile of the part of the cross-sectional tubular corner bracket 30 which is to be connected to the housing 14 .

[0031] Here, the housing 14 has a conical shape with a section 16 which is likewise conical, but extends at a more gradual angle. The flange 12 is here connected to the tapering end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com