One-piece three-axis linkage composite automatic press-fitting machine

A three-axis linkage and integrated technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of poor compatibility of multi-model press-fitting in the production line, poor compatibility of composite models of the same model, and increase the difficulty of manufacturing line parts and other issues, to achieve the effects of saving production funds and manpower input, good system compatibility, and obvious overlapping linkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

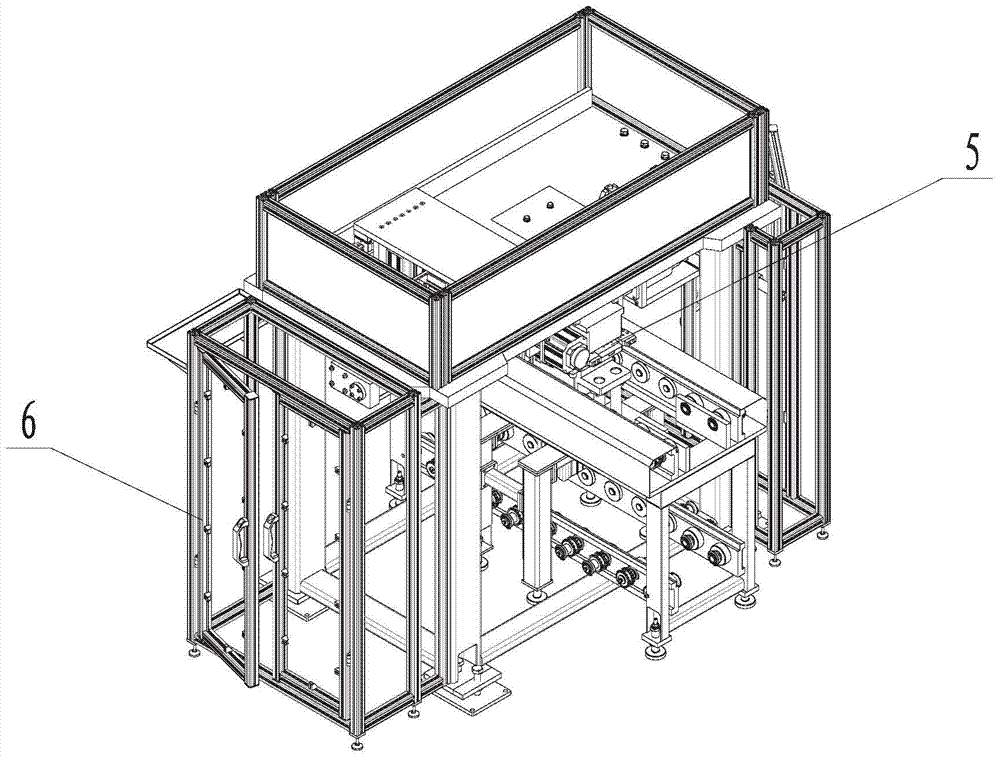

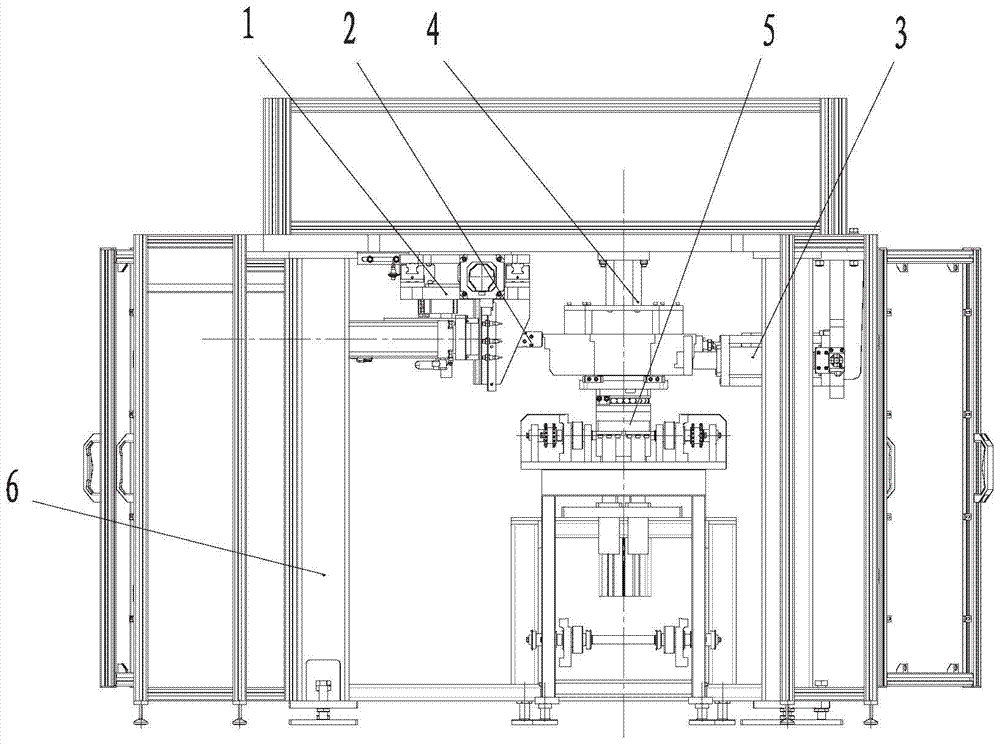

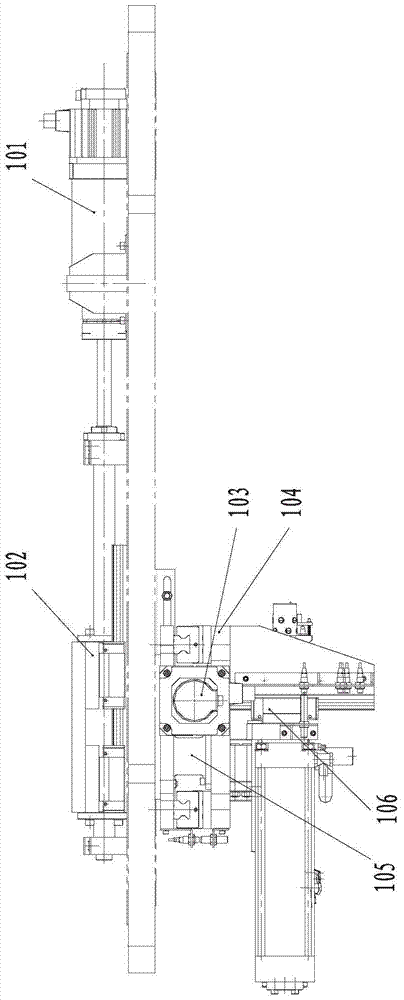

[0043] Such as figure 1 , figure 2 As shown, the present invention includes a body 6 and a horizontal positioning system and a vertical positioning system arranged on the body 6, and the body 6 adopts a "Π" form. The horizontal positioning system includes an integrated three-axis linkage positioning structure 1 and a reverse thrust execution structure 3 respectively arranged on both sides of the body 6. The integrated three-axis linkage positioning structure 1 is equipped with The press-fit execution structure 2. The vertical positioning system includes an upper limit structure 4 and a line body jacking structure 5 respectively arranged on the top and bottom of the machine body 6 and corresponding to each other. The workpiece to be pressed (engine cylinder head) is placed on the line body lifting structure 5, and is lifted up by the line body lifting structure 5 un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com