Automatic production line for plastic grafting clips

An automatic production line and grafting clip technology, applied in the field of agricultural grafting, can solve the problems of easy towing, entanglement, affecting the production efficiency and quality of plastic grafting clips, and different belt tension, so as to improve the scope of use, facilitate replacement, The effect of improving replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described below with reference to the drawings. In order to fully understand the present invention, many details are described below, but for those skilled in the art, the present invention can be implemented without these details.

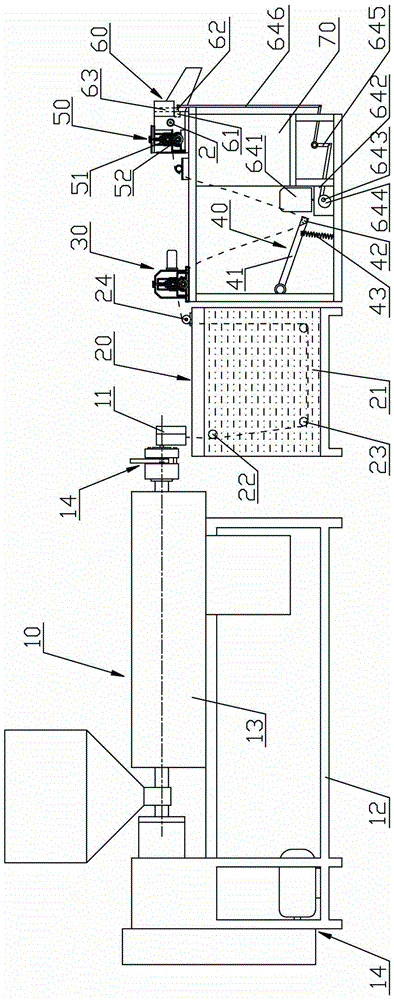

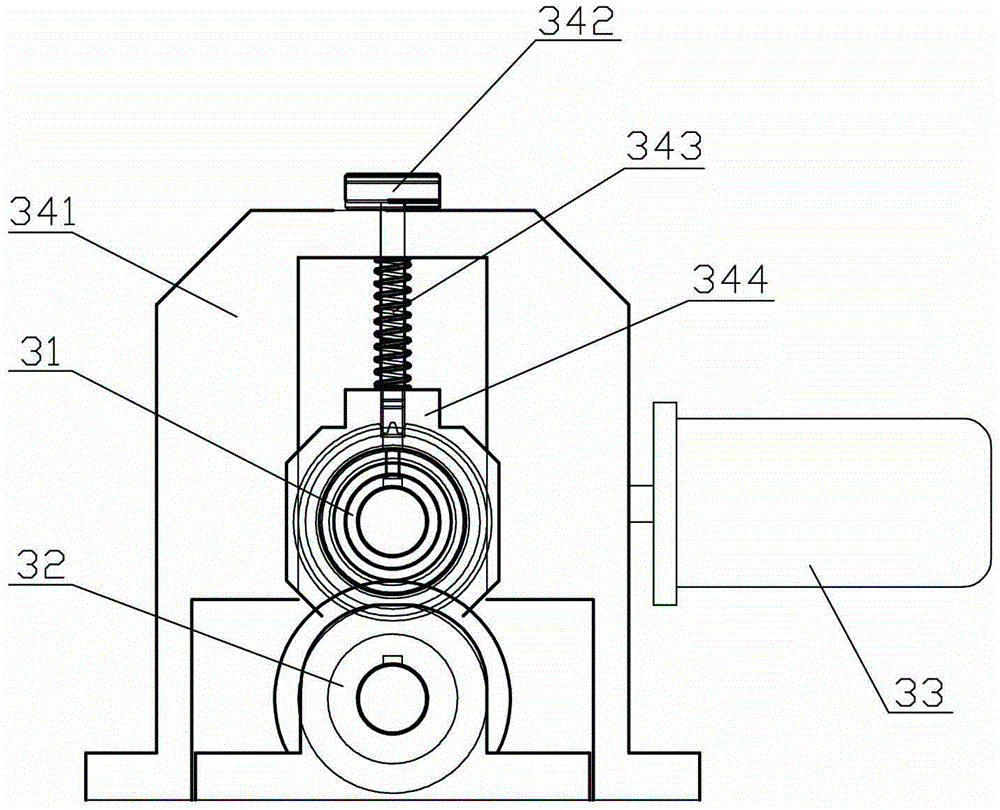

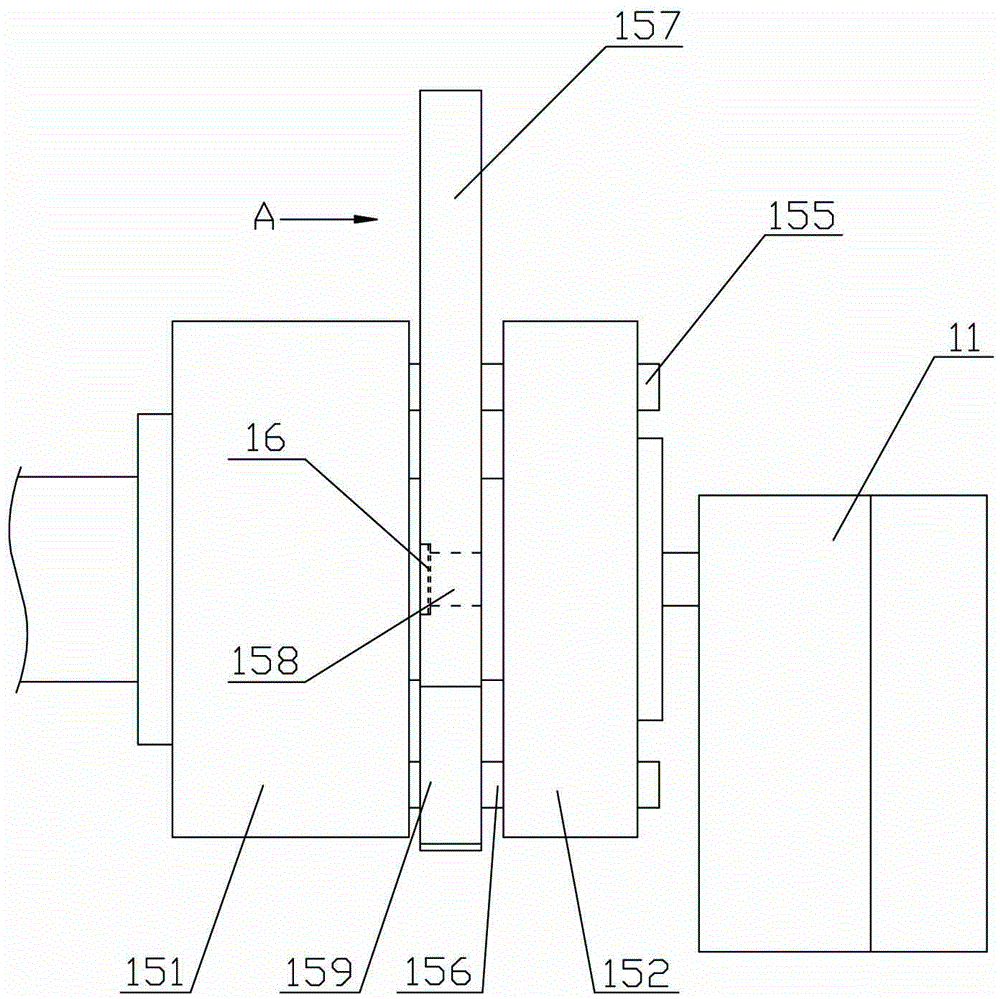

[0026] An automatic production line for plastic grafting clamps, refer to figure 1 , Including a screw extruder 10, a cooling mechanism 20, a towing mechanism 30, a tension control mechanism 40, a tape feeding mechanism 50, and a cutting mechanism 60 arranged in sequence. The end of the screw extruder 10 is connected to a grafting clip forming die 11, the cooling mechanism 20 includes a cooling groove 21, and the cooling groove 21 is provided with at least a belt guide pulley 22, a immersion guide pulley 23 and A belt guide pulley 24, the outlet of the grafting clip forming mold 11 is vertically downward and is arranged corresponding to the belt guide pulley 22 in the cooling tank 20; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com