Automobile wheel trim

A wheel eyebrow and automobile technology, applied in the field of automobile wheel eyebrows and auto parts, can solve the problems of potential safety hazards, low processing efficiency, poor energy absorption effect, etc., achieve high-efficiency energy absorption, eliminate potential safety hazards, and reduce damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing of description, the present invention will be further described.

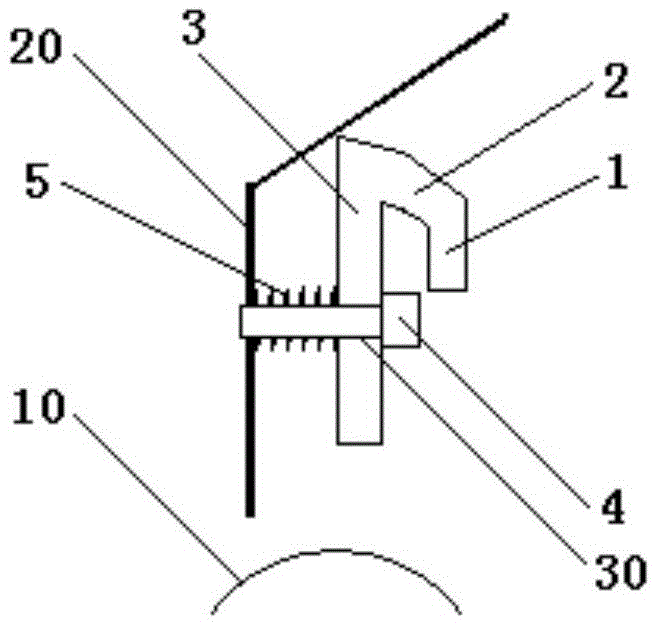

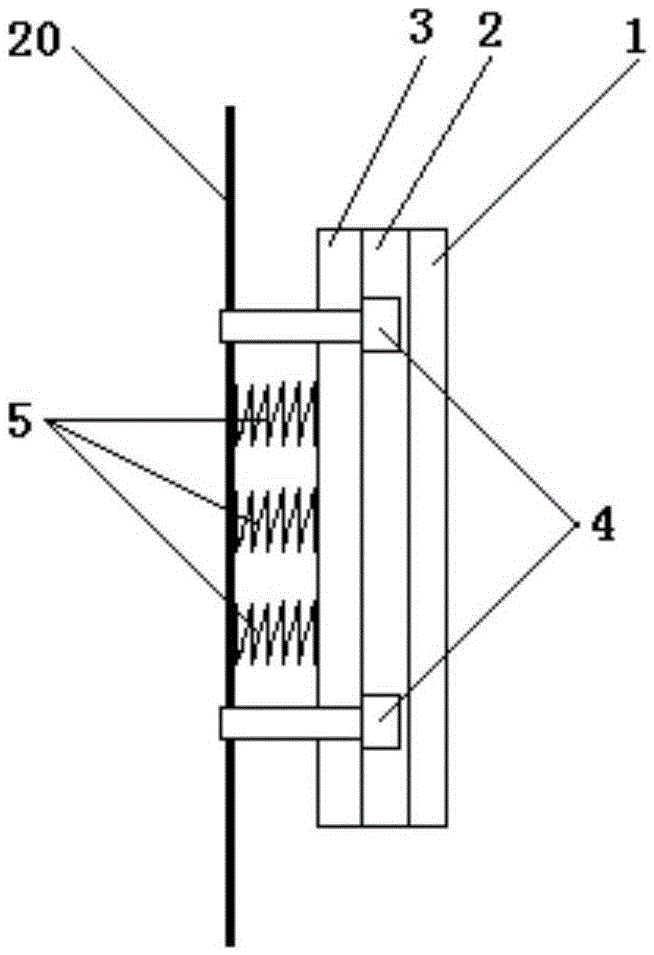

[0018] like figure 1 and figure 2 A kind of automobile wheel frown shown, comprises the outer plate 1, the top plate 2 and the inner plate 3 that are successively connected to the opening facing the automobile tire 10; The inner plate 3 is provided with a mounting hole 30 for fastening bolts 4 to pass through. The fastening bolt 4 penetrates the mounting hole 30 and is fixed on the automobile fender 20 through the tail to fix the inner panel 3 with the automobile body; The elastic members 5 distributed in parallel, the elastic members 5 are preferably steel wire springs or rubber spring coils, have a simple structure, and are economical and practical.

[0019] The bottom end of the inner plate 3 is provided with a mounting edge (not shown in the figure), and the mounting edge exceeds the bottom end of the outer plate 1; the mounting hole 30 is opened on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com