Ship noise reduction device

A technology for ships and pallets, which is applied in the field of ship noise reduction devices, can solve the problems of no major innovations, etc., and achieve the effects of saving economic costs, reducing vibration and sound radiation, and improving production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

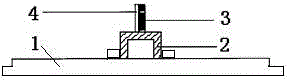

[0009] The present invention will be further explained below in conjunction with the accompanying drawings.

[0010] A ship noise reduction device, characterized in that it includes a supporting plate 1, a hollow vibration-proof mass block 2, a sound-absorbing material 3 and a belt plate 4, the hollow vibration-proof mass block 2 is installed on the supporting plate 1, and the supporting plate The middle of the plate is disconnected, and the hollow vibration-absorbing mass is fixed between two supporting plates;

[0011] The sound-absorbing material 3 is polyurethane, and the average sound absorption coefficient in the 10-3K frequency band is over 85%. The hollow anti-vibration mass 2 is a high-shear modulus and high-density metal material. The cross-sectional size of the hollow anti-vibration mass 2 is about 8-10 times the thickness of the supporting plate, the weight 2 of the hollow anti-vibration mass block should be greater than 60 of the total weight of the solid an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com